Split type vacuum thermal insulation ultrasonic electromagnetic frying pan

A technology of vacuum heat preservation and electromagnetic frying pan, which is applied in the field of electric frying pan, which can solve the problems of easy loss of heat, long heating time, and difficulty in cleaning, etc., achieve the effects of rapid heating and cooking of food, ensuring nutritional value, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the split type vacuum heat preservation ultrasonic electromagnetic frying pan of the present invention will be described in detail below in conjunction with the accompanying drawings.

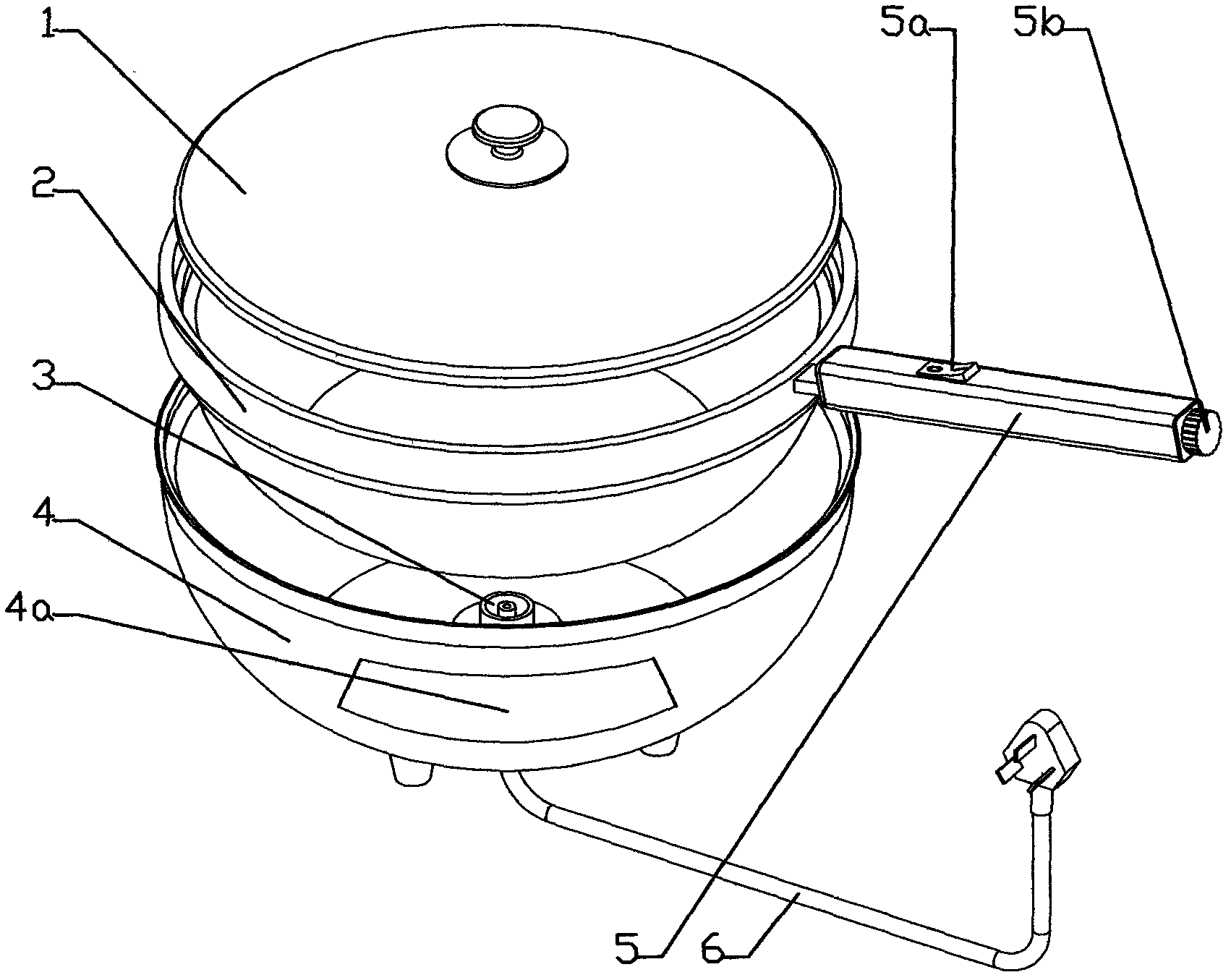

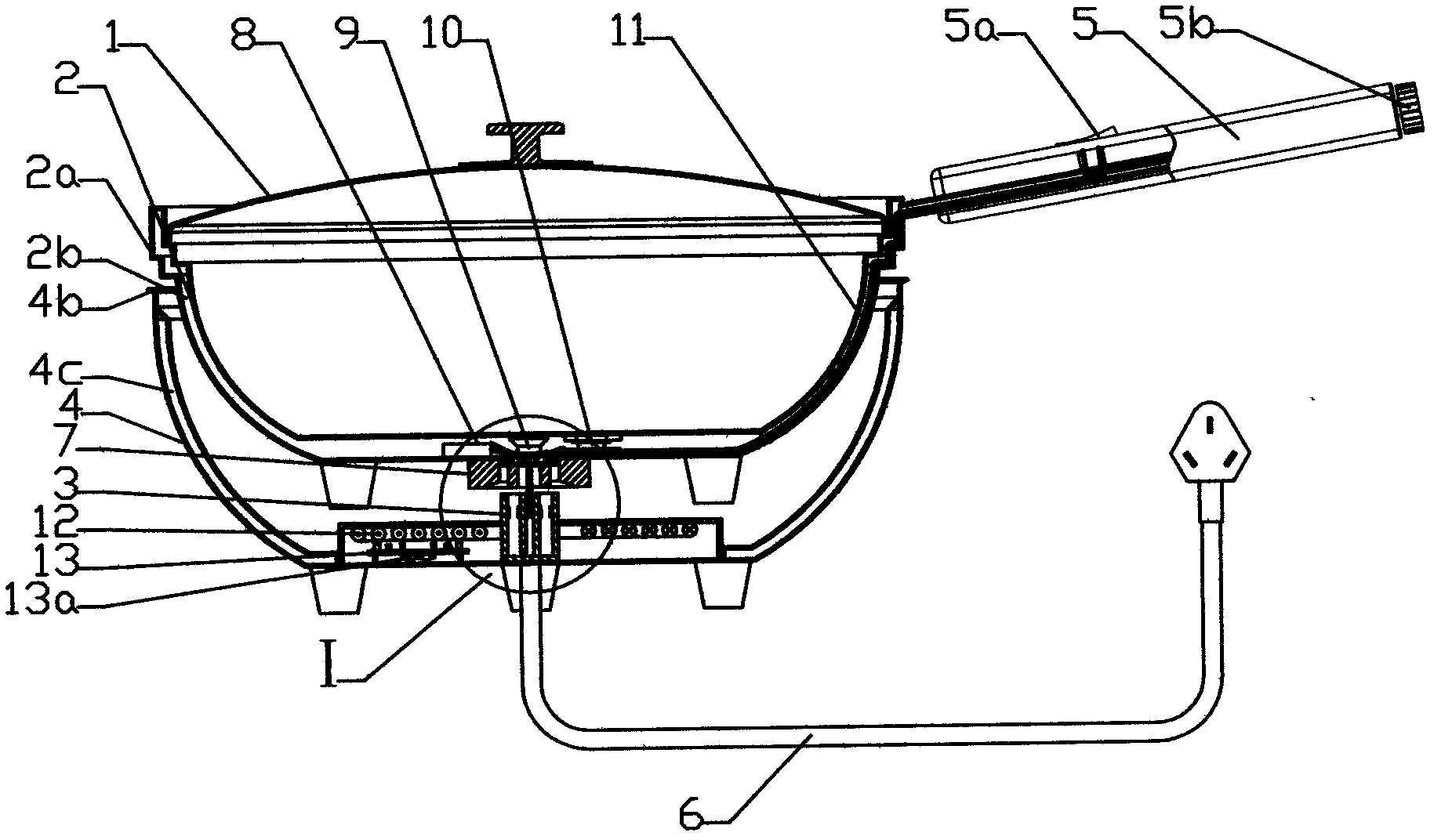

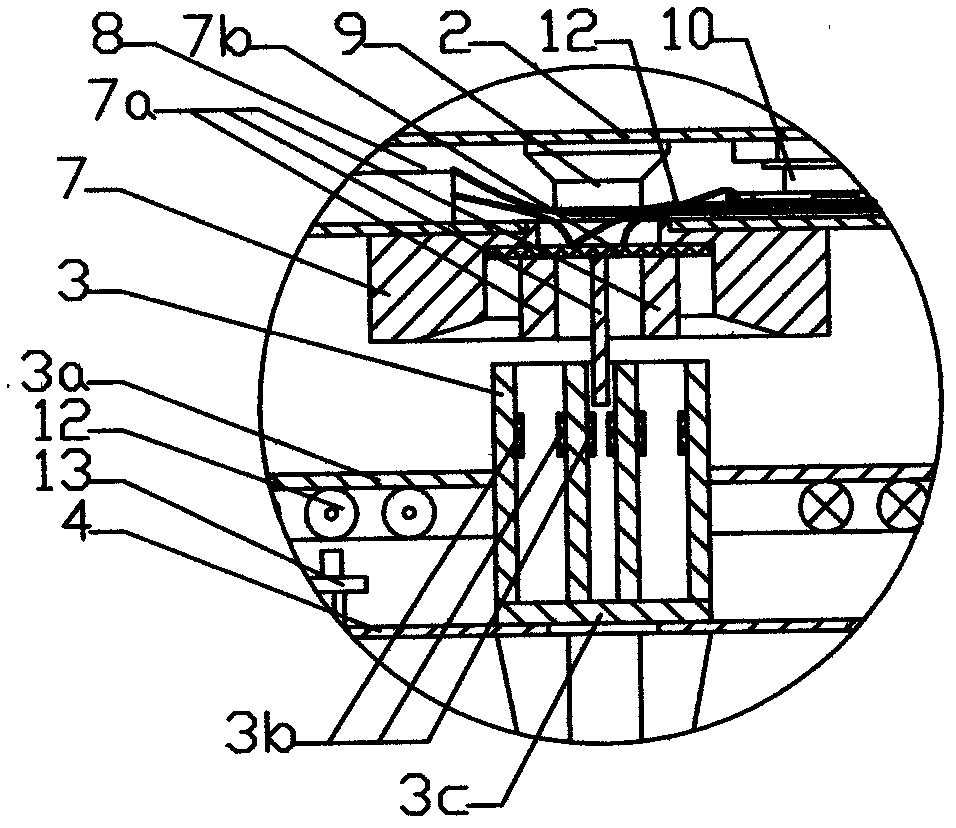

[0018] Such as figure 1 , 2 As shown, a split-type vacuum heat preservation ultrasonic electromagnetic frying pan includes a pot cover 1, a pot body 2, a pot handle 5, a base 4 used with the pot body 2, an ultrasonic device installed on the pot body 2 and a temperature control device. device, and the electromagnetic heating device contained in the base 4.

[0019] Such as figure 2 As shown, the pot body 2 is a double-layer pot body, and its inner cavity is a heat-insulating cavity 2b, which can be a vacuum chamber for more heat preservation. It is a thermal insulation chamber 4c, which can be a vacuum chamber. There is a step 4b matching the above-mentioned ladder structure on the edge of the base 4, which facilitates the placement of the double-layer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com