Roller conveyor and method for operating same

A conveyor and roller technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as the height of the roller body, and achieve the effects of improving heat load, stabilizing supply voltage, and avoiding overvoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] At the outset, it should be pointed out that the same reference symbols or the same component designations are used for the same components in the differently described embodiments, wherein the disclosure content contained in the entire description can be transferred to the components with the same reference symbols or the same component designations. parts. Likewise, positional indications such as top, bottom, side, etc. selected in the description relate to the currently described and illustrated figure and can be transferred to the new position as appropriate in the event of a position change.

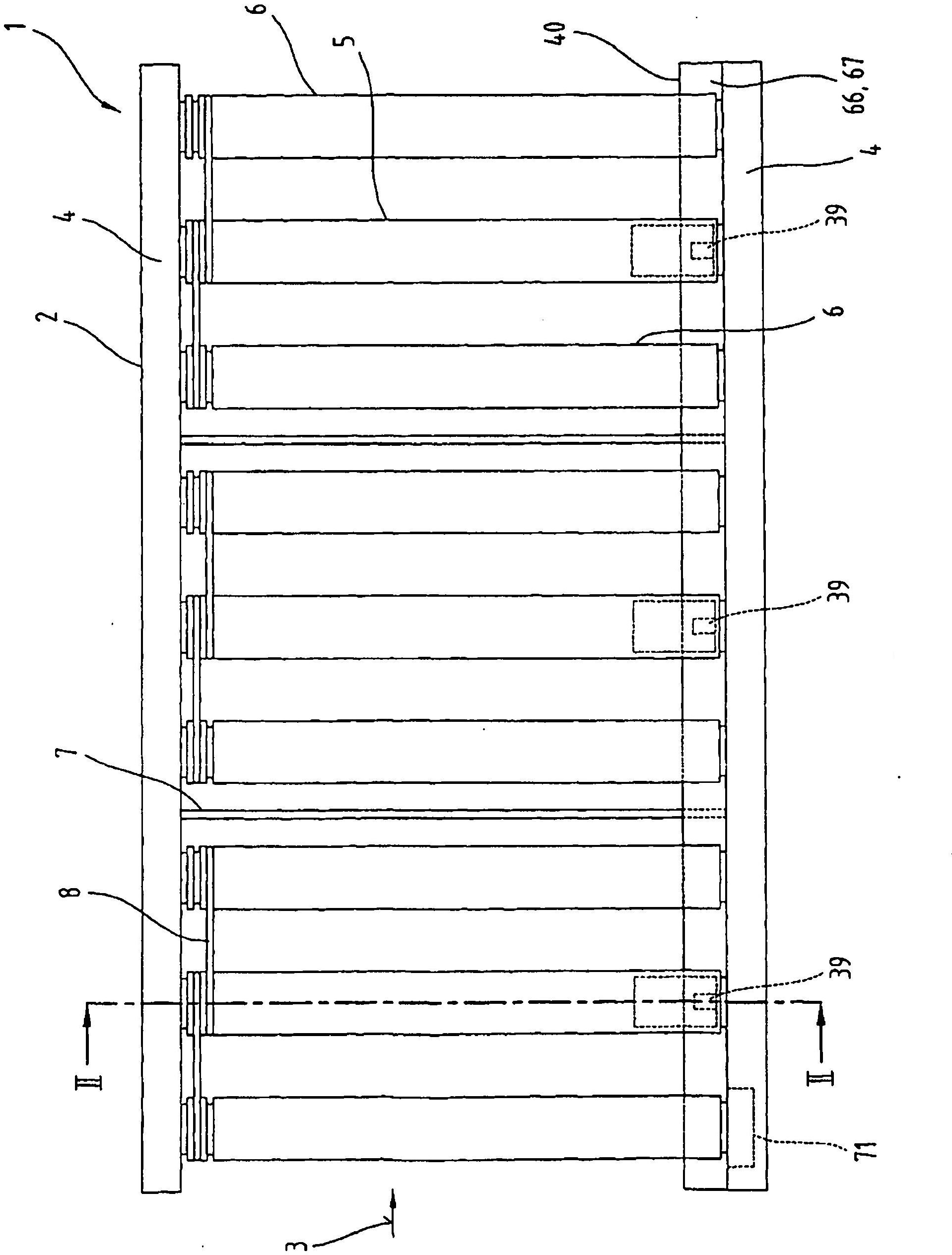

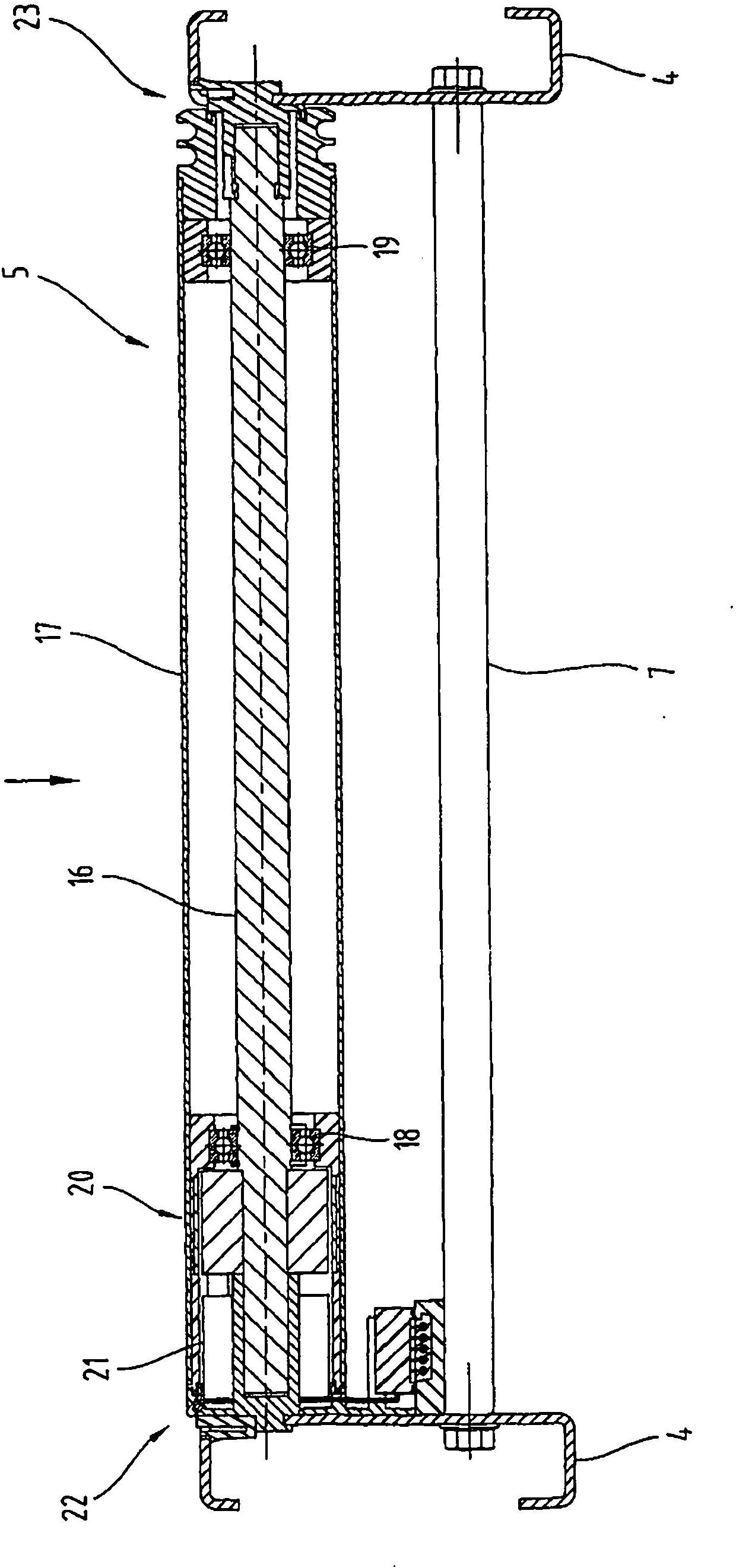

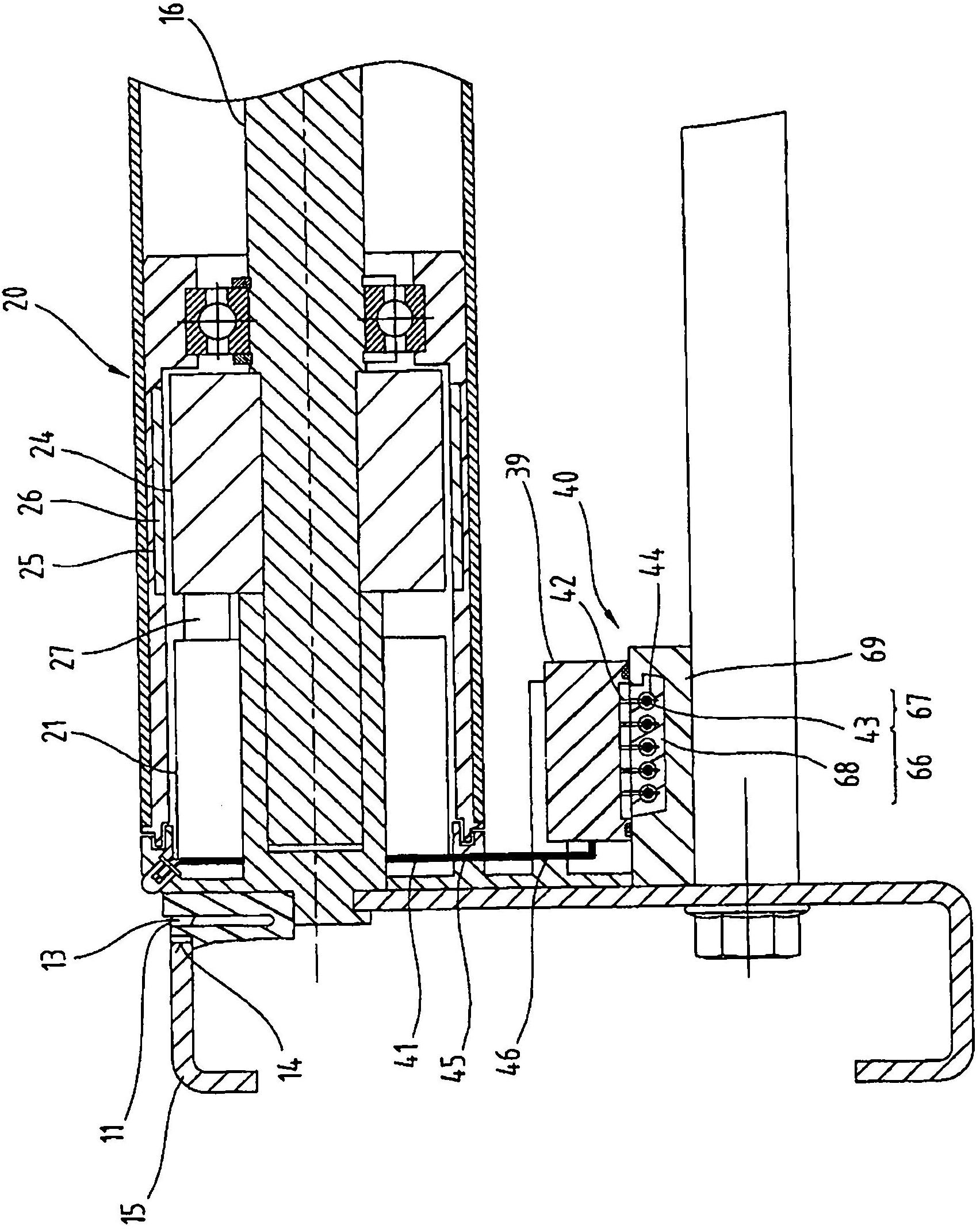

[0029] figure 1 shows a partial plan view of a conveyor system with a roller conveyor 1 for conveying loads, such as containers. The conveying device 1 comprises a frame 2 with a frame profile 4 extending parallel to the conveying direction 3 and conveying rollers 5, 6, wherein the conveying roller 5 is equipped with a motor (drive motor) which will be explained in detail fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com