Flexible flat cable assembly and assembling method thereof

A technology of flexible flat and cable components, which is applied in the field of flexible flat cable components and their assembly, which can solve the problems of soldering short circuit and the inability to accurately control the amount of tin, etc., and achieve the effect of good electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

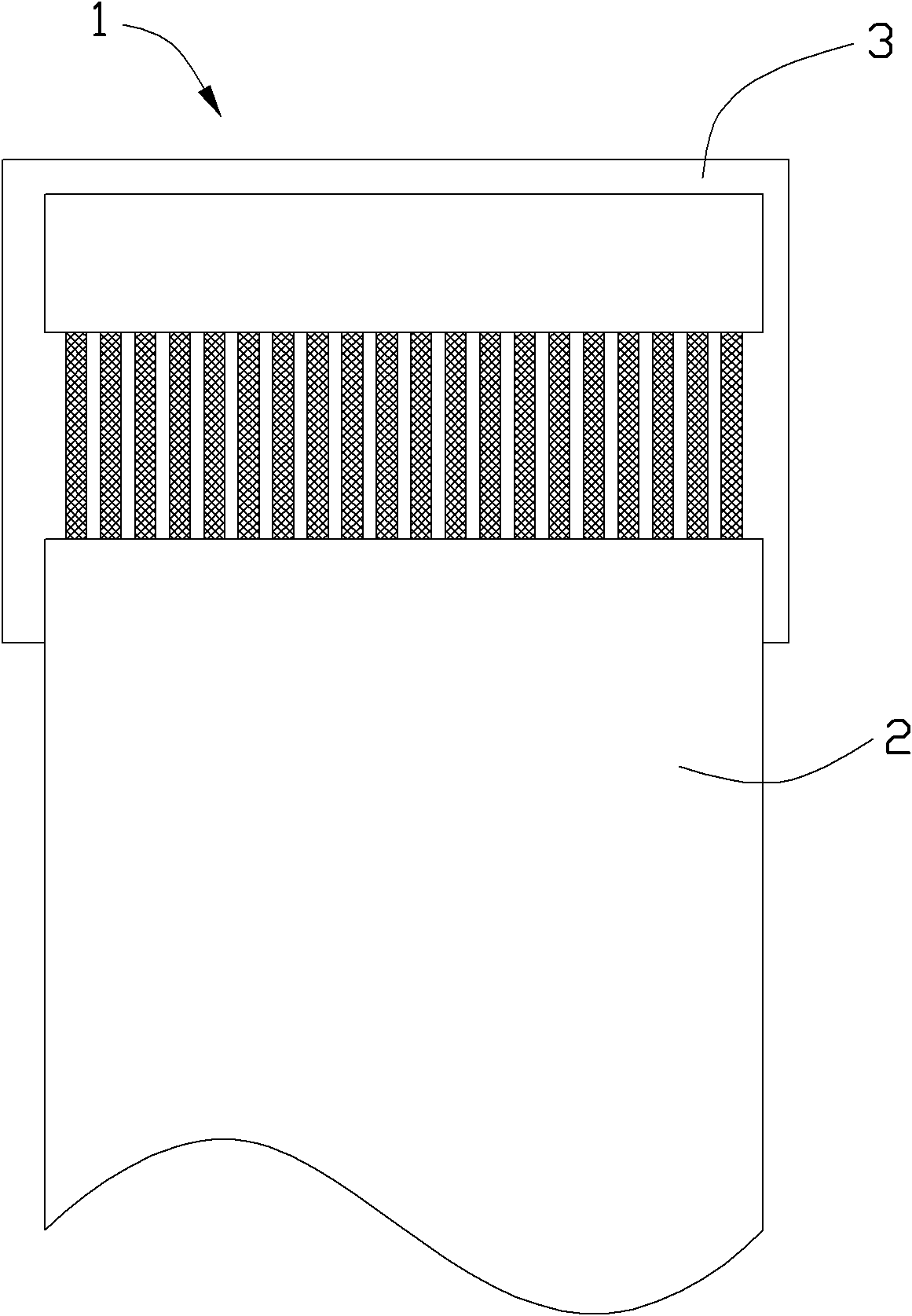

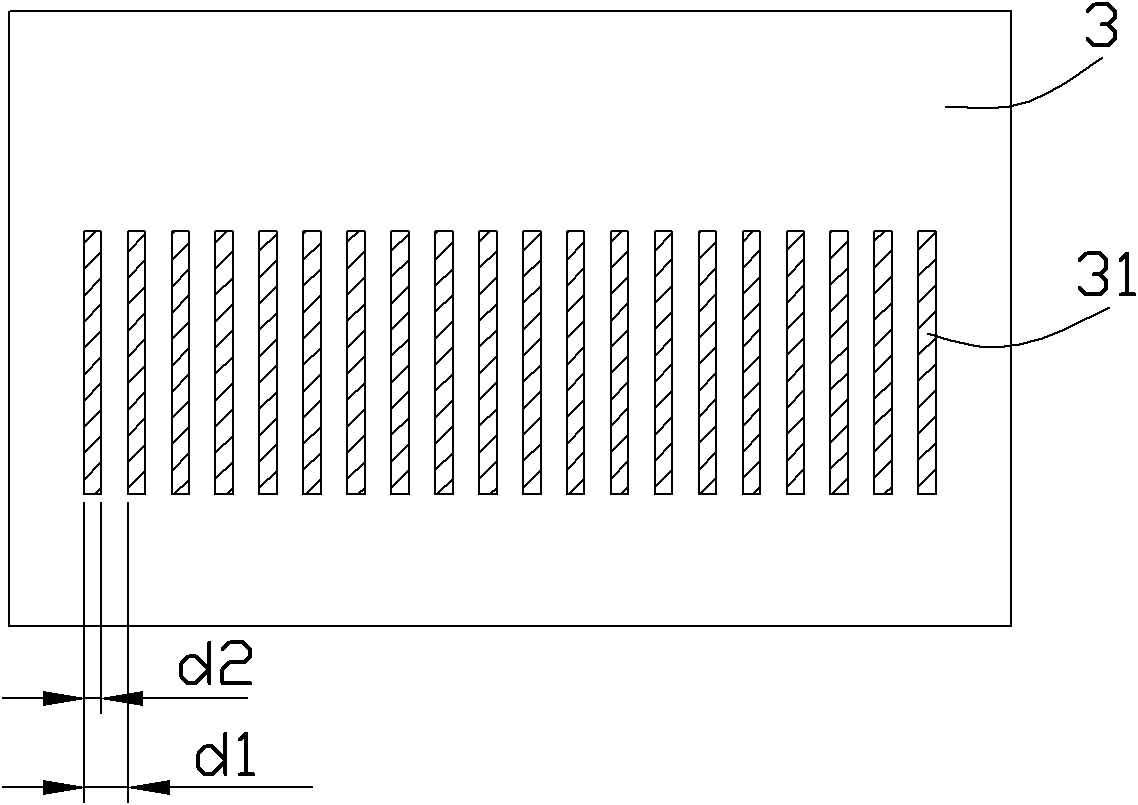

[0016] see figure 1 , the flexible flat cable assembly 1 of the present invention includes a flexible flat cable 2 and a printed circuit board 3 welded together with the flexible flat cable 1 .

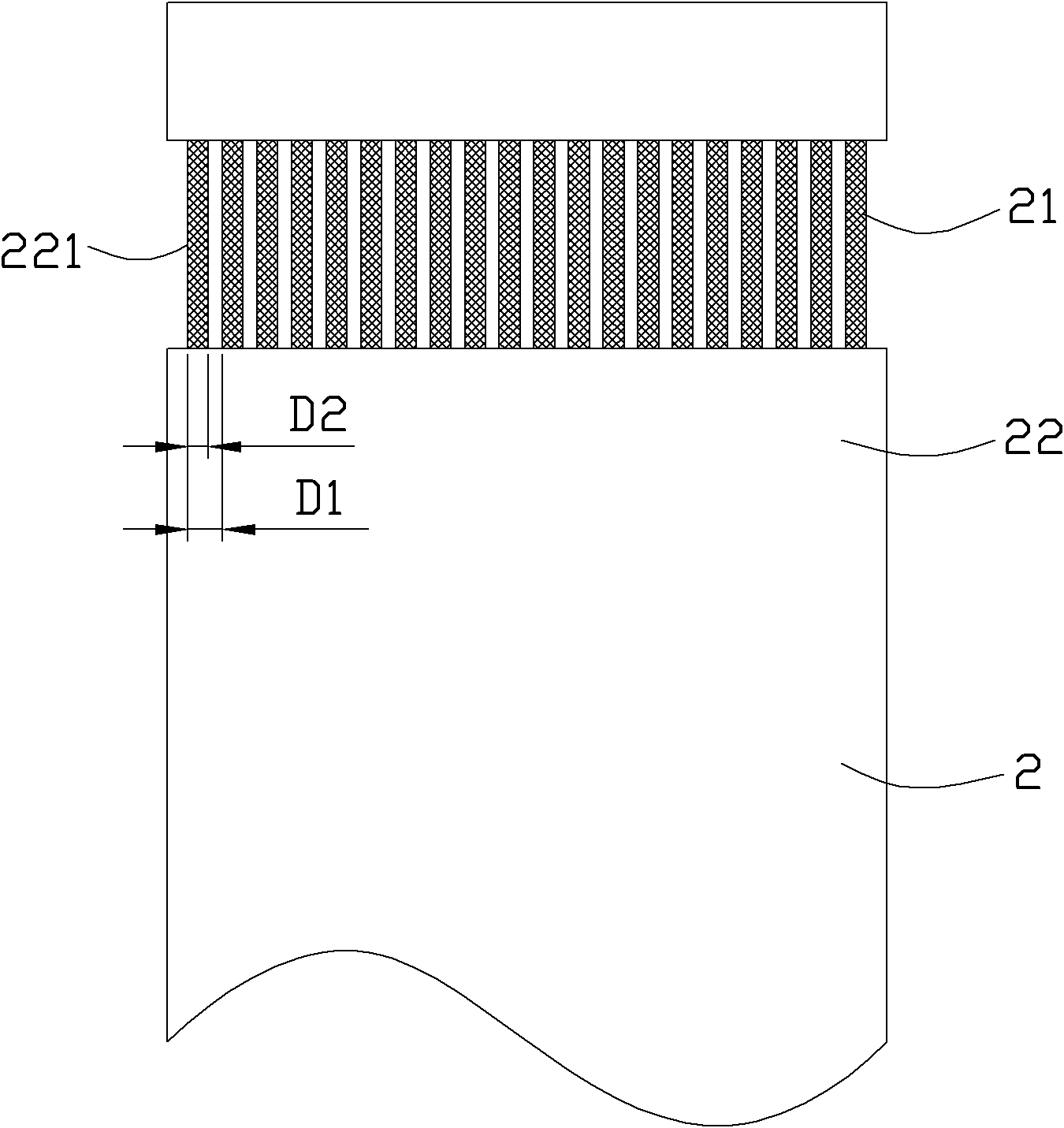

[0017] see figure 2 , the flexible flat cable 2 includes a plurality of conductors 21 arranged in parallel and at intervals in the transverse direction and an insulator 22 covering the conductors 21 . The insulator 22 of the flexible flat cable 2 is provided with a gap 221 so that a section of the conductors 21 in the longitudinal direction is exposed outside the insulator 22 in the vertical direction, and a free end of the conductors 21 is still covered by the insulator 22 . The distance ( D1 ) between two adjacent conductors 21 in the plurality of conductors 21 is less than 0.5mm, and the specific value can be set as 0.5mm, 0.4mm, 0.3mm, 0.2mm and other values. When the distance ( D1 ) between two adjacent conductors 21 is 0.5 mm, the width ( D2 ) of the conductors 21 is 0.3 mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com