High-performance ferrocement laminate (HPFL) reinforcement layer bond slip test device and method

A test device and reinforcement layer technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems that the strain gauge measurement cannot meet the experimental requirements, the loading system is designed separately, the shape of the failure surface is complex, etc., and the test process is safe and reliable. , High practical value, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

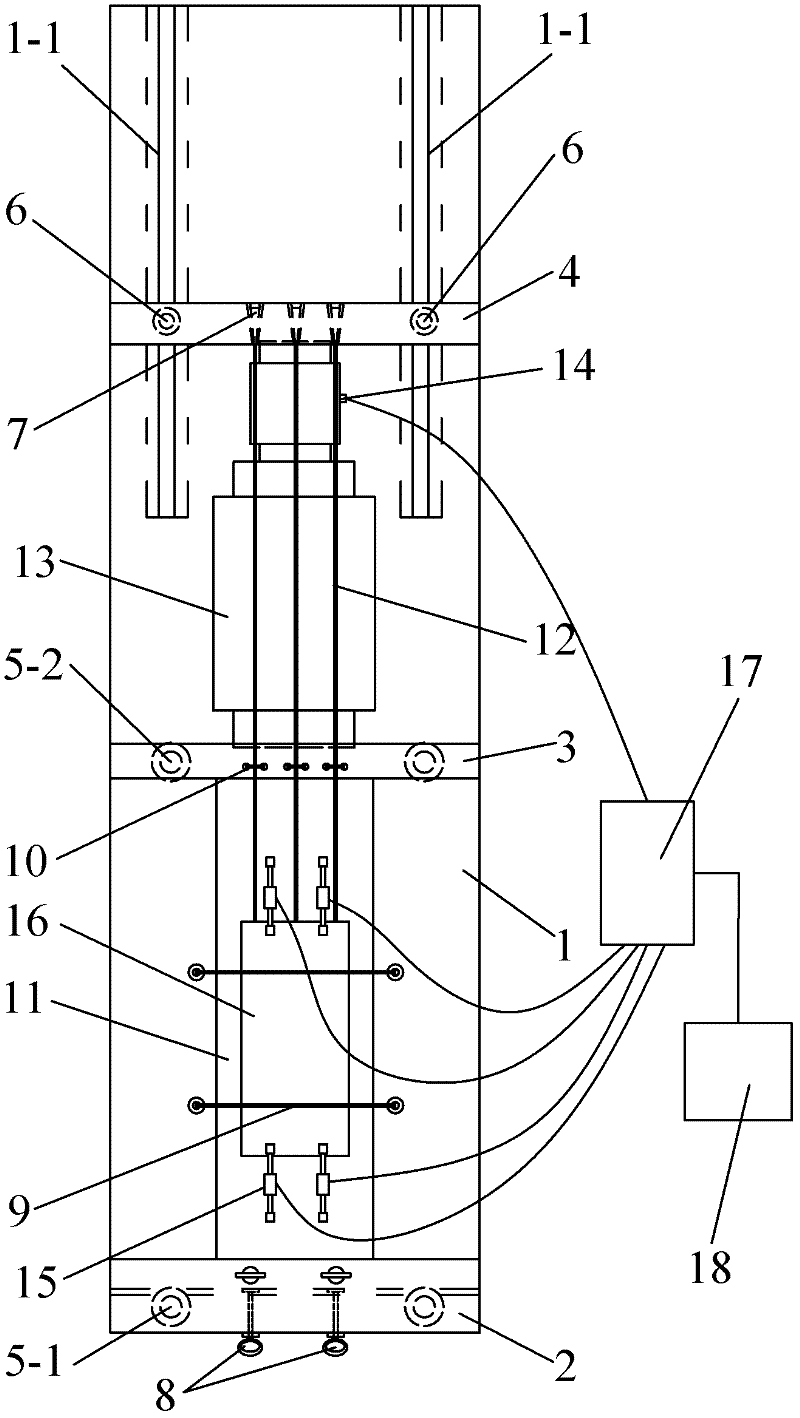

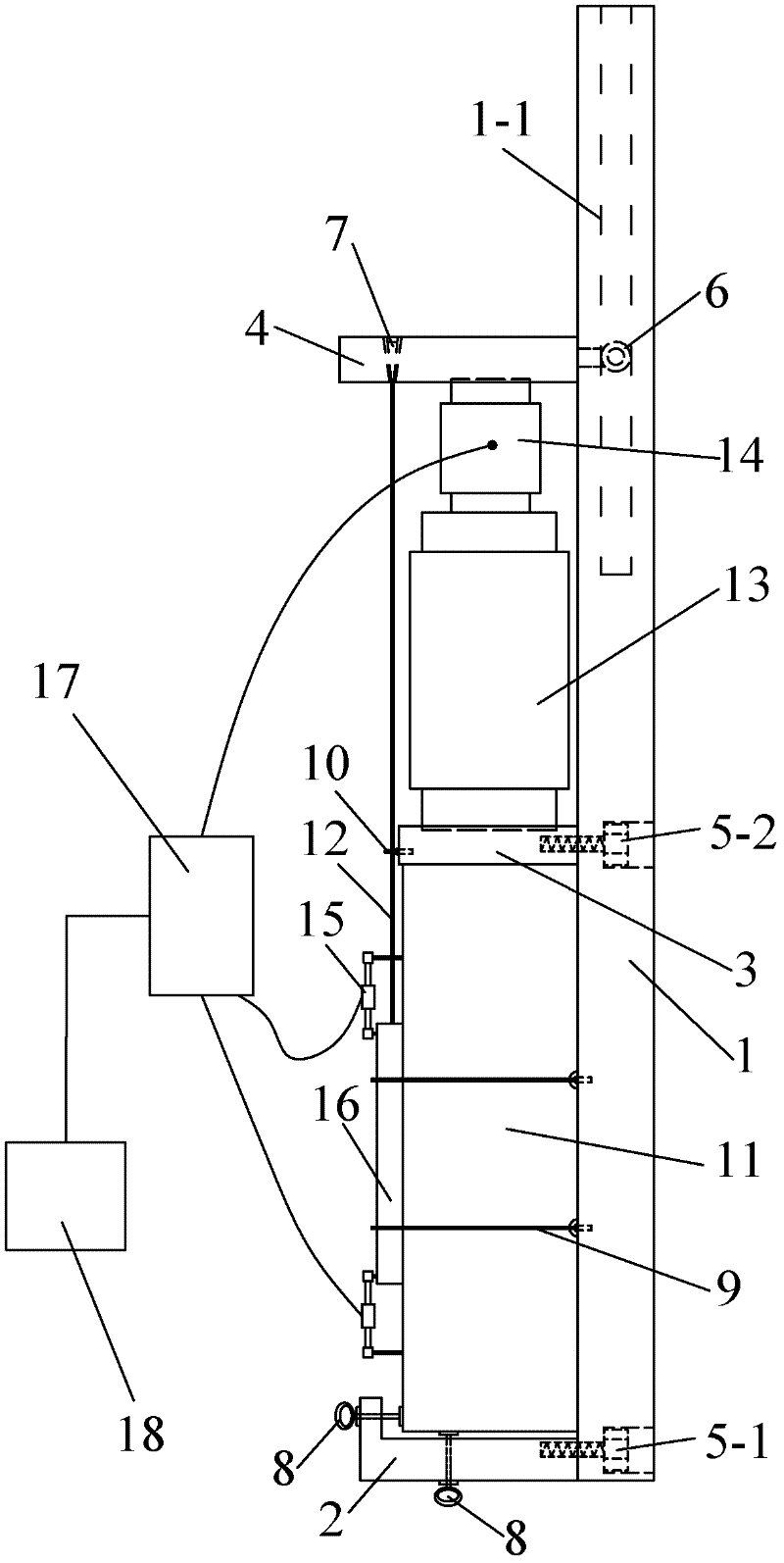

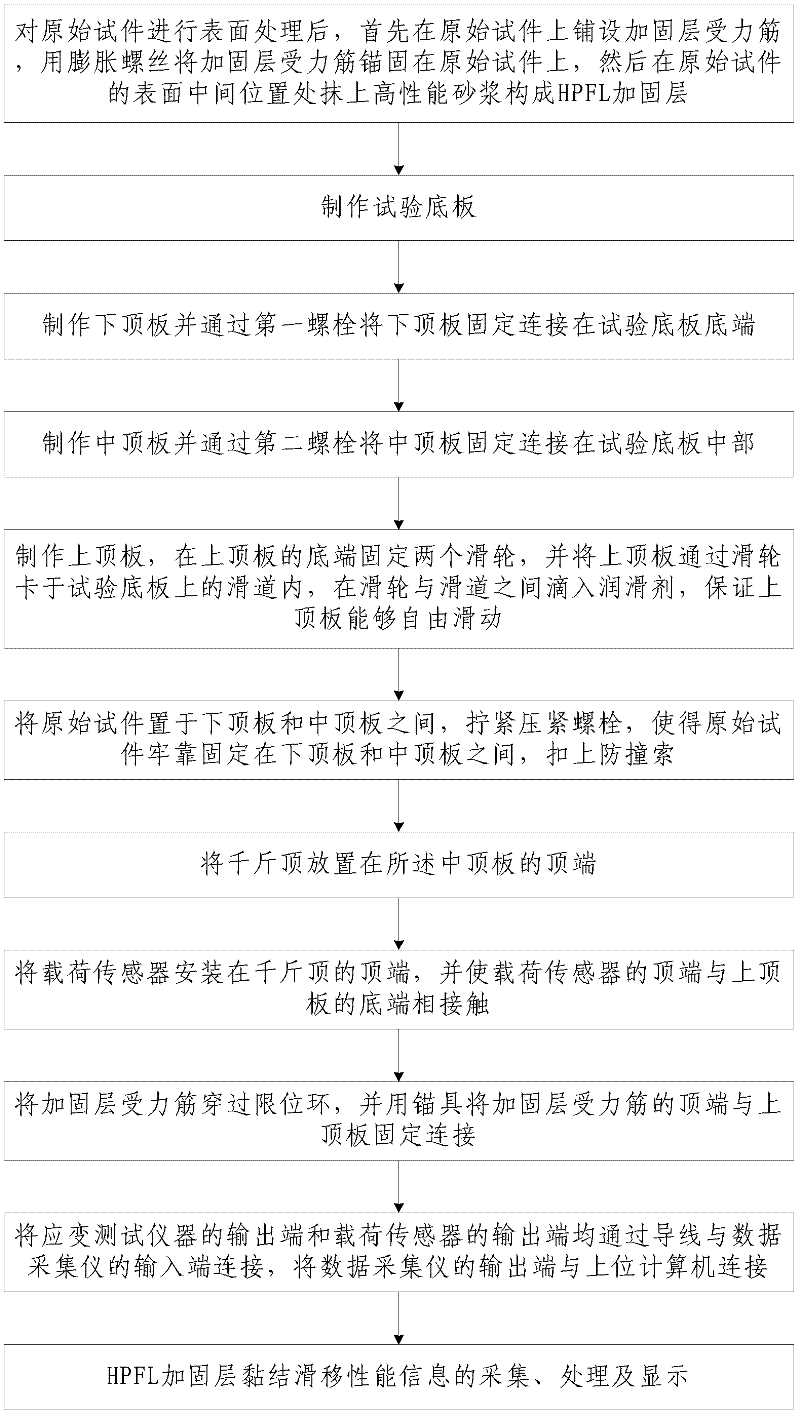

[0047] like figure 1 and figure 2 As shown, in the HPFL reinforcement layer bond-slip test device of the present invention, the HPFL reinforcement layer 16 is arranged at the middle position of the surface of the original test piece 11, and the HPFL reinforcement layer 16 is embedded with a reinforcement layer stress Rib 12, the HPFL reinforcement layer bond-slip test device includes a test bottom plate 1, a lower top plate 2 fixedly connected to the bottom of the test bottom plate 1 and used to fix the original test piece 11, and a middle top plate 3 fixedly connected to the middle of the test bottom plate 1 and the upper top plate 4 that is slidingly connected to the upper half of the test bottom plate 1, and embedded in the joint position of the HPFL reinforcement layer 16 and the original specimen 11 and used to measure the strain within a certain distance at the joint position of the HPFL reinforcement layer 16 and the original specimen 11 One or more strain testing ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com