Multi-field coupled loading micro nanometer press-in testing system and method

A test system, micro-nano technology, applied in the direction of applying stable tension/pressure to test material strength, test material hardness, and measuring devices, etc., can solve problems such as increased system flexibility, reduced frame flexibility, and occupancy. Achieve the effect of high precision, high feasibility and reliability of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

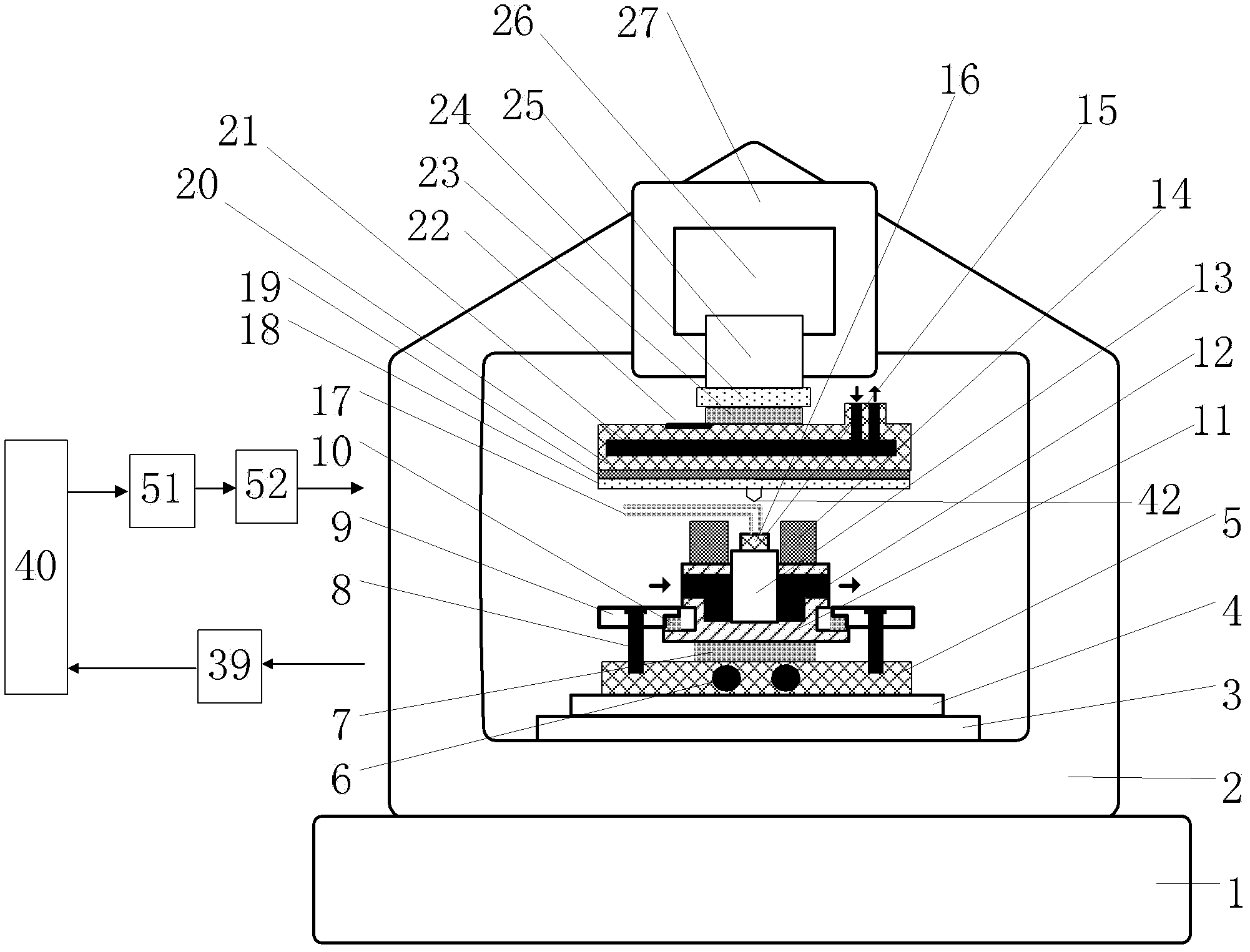

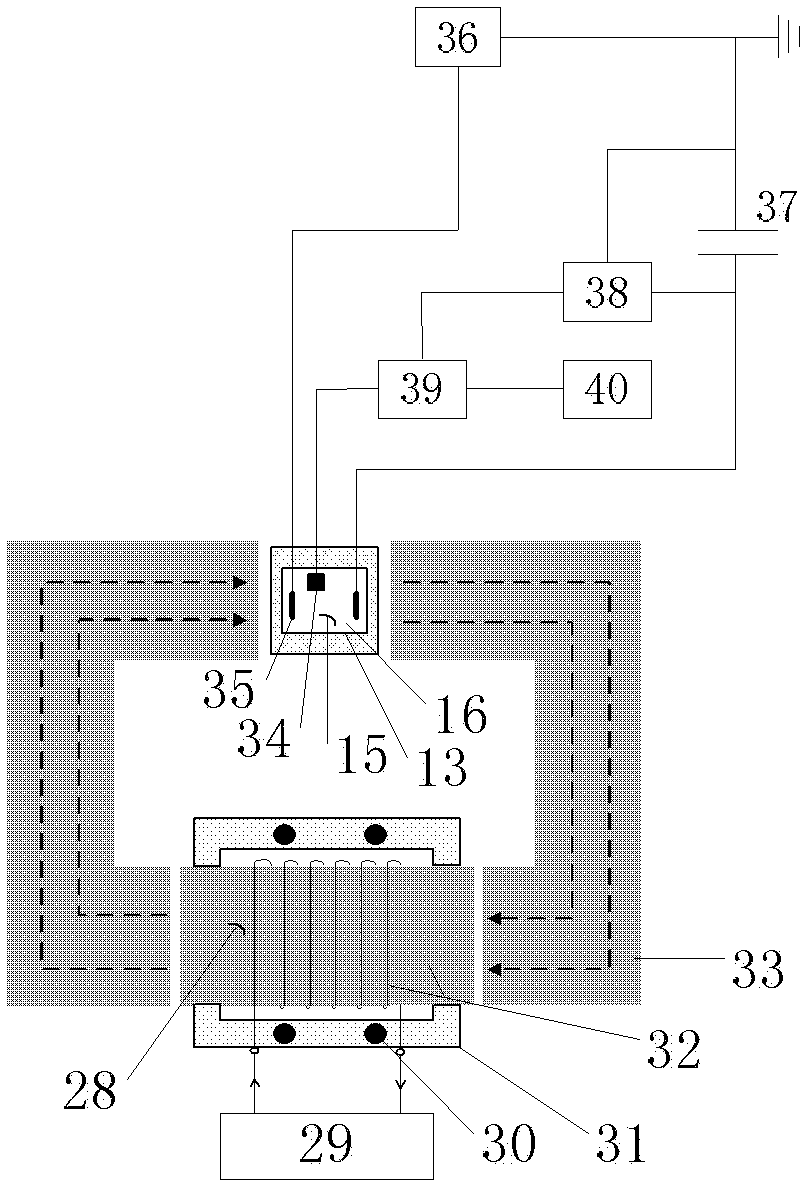

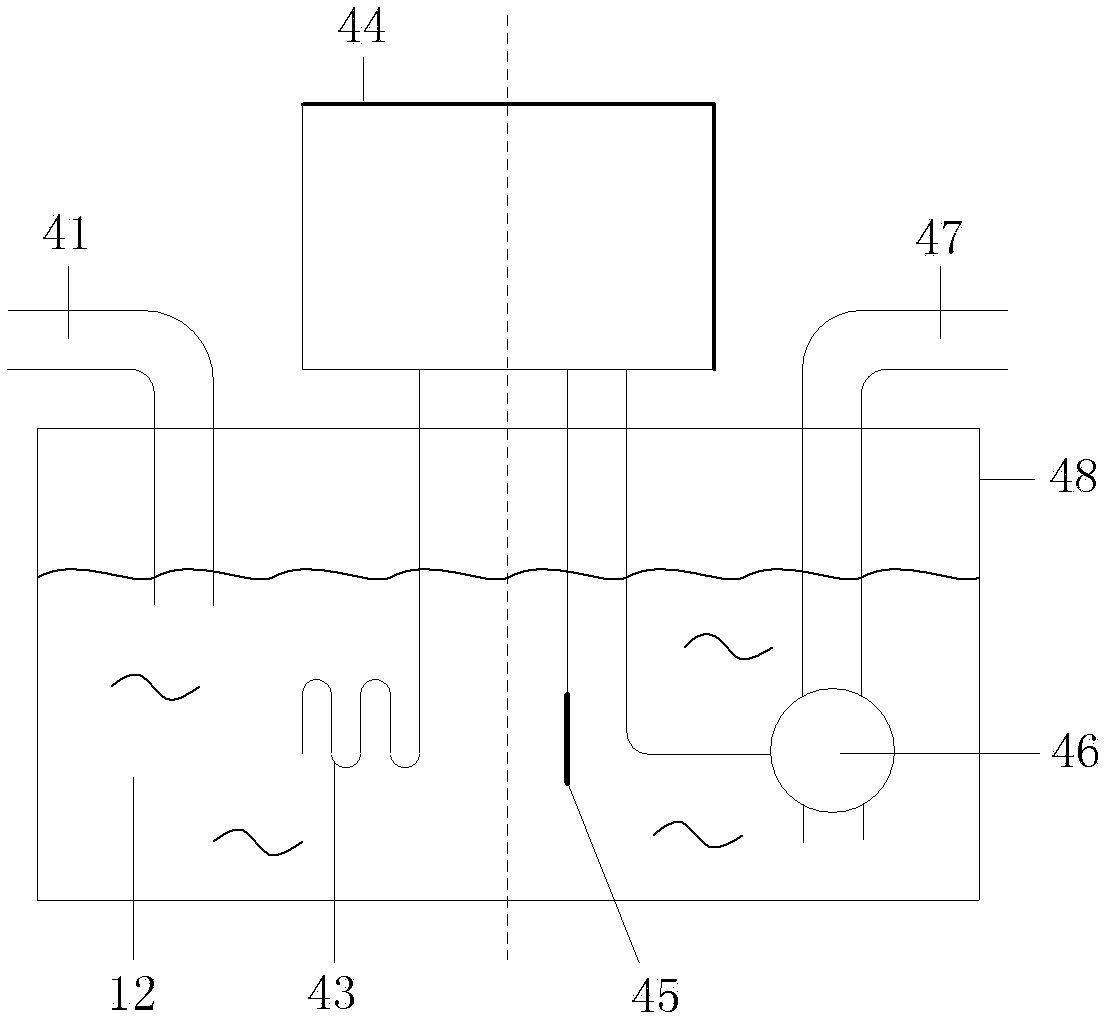

[0041] The invention provides a multi-field coupled loading micro-nano indentation test system, which consists of four parts: mechanical loading and measurement subsystem, electric field loading and measurement subsystem, magnetic field loading and measurement subsystem, and circulating oil bath thermal field loading and measurement subsystem composition. The mechanical loading and measurement subsystem includes a main frame 2, a horizontal coarse adjustment mobile platform 3 for horizontal position adjustment for testing, a horizontal precision mobile platform 4, and a motor drive unit 26 for vertical vertical position coarse adjustment for testing. The motor driving unit 26 is connected to the main frame 2 through the connection panel 27, and the lower end is connected in series with the piezoelectric stack driving unit 25, and the lower end of the piezoelectric stack driving unit 25 is respectively connected to the precision force sensor 24 and the capacitive displacement se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com