Support frame and stopping structure

A technology of support frame and reset structure, applied in the field of support frame, can solve the problems of display defects, influence on display quality, impact, etc., and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

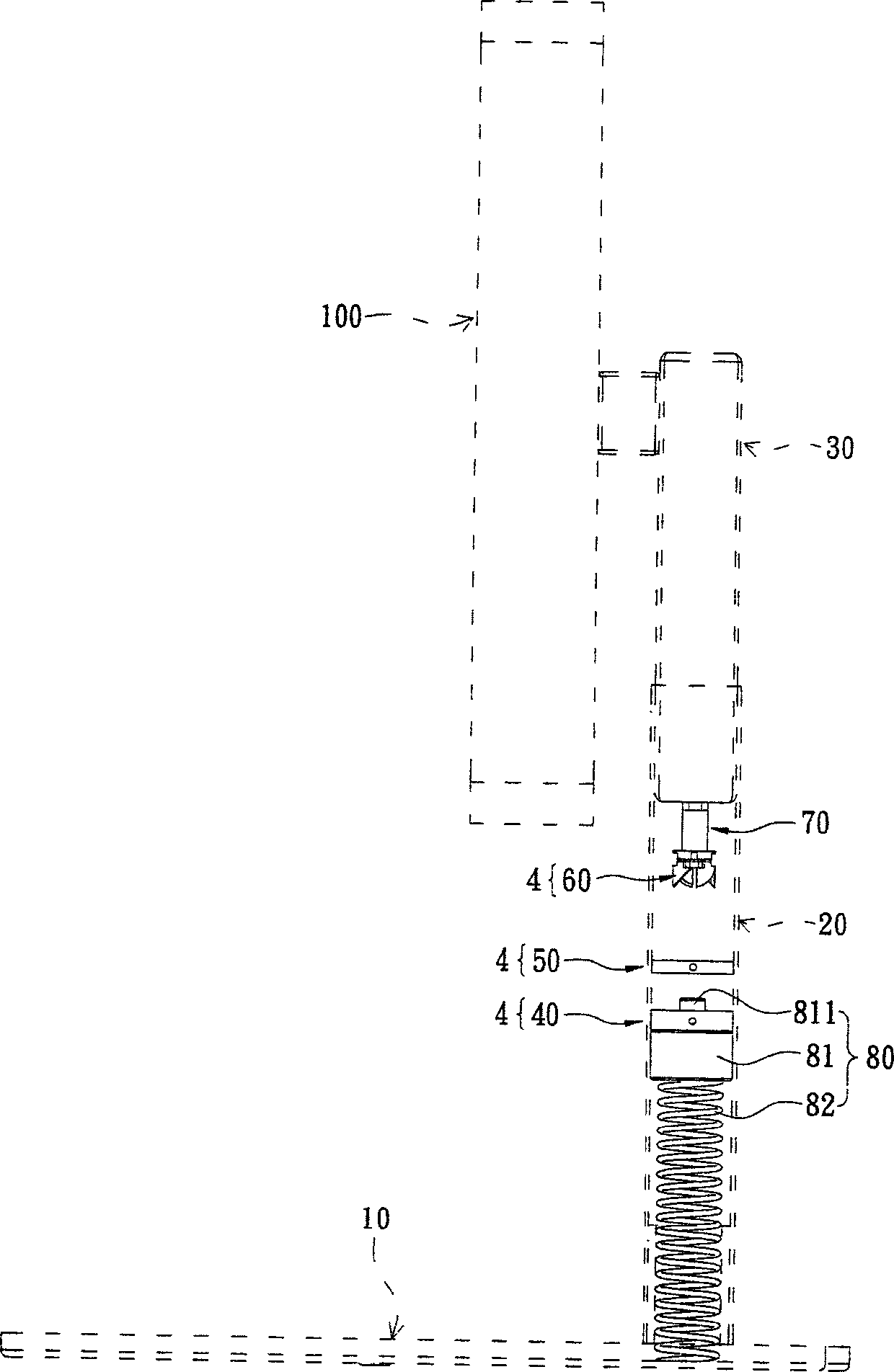

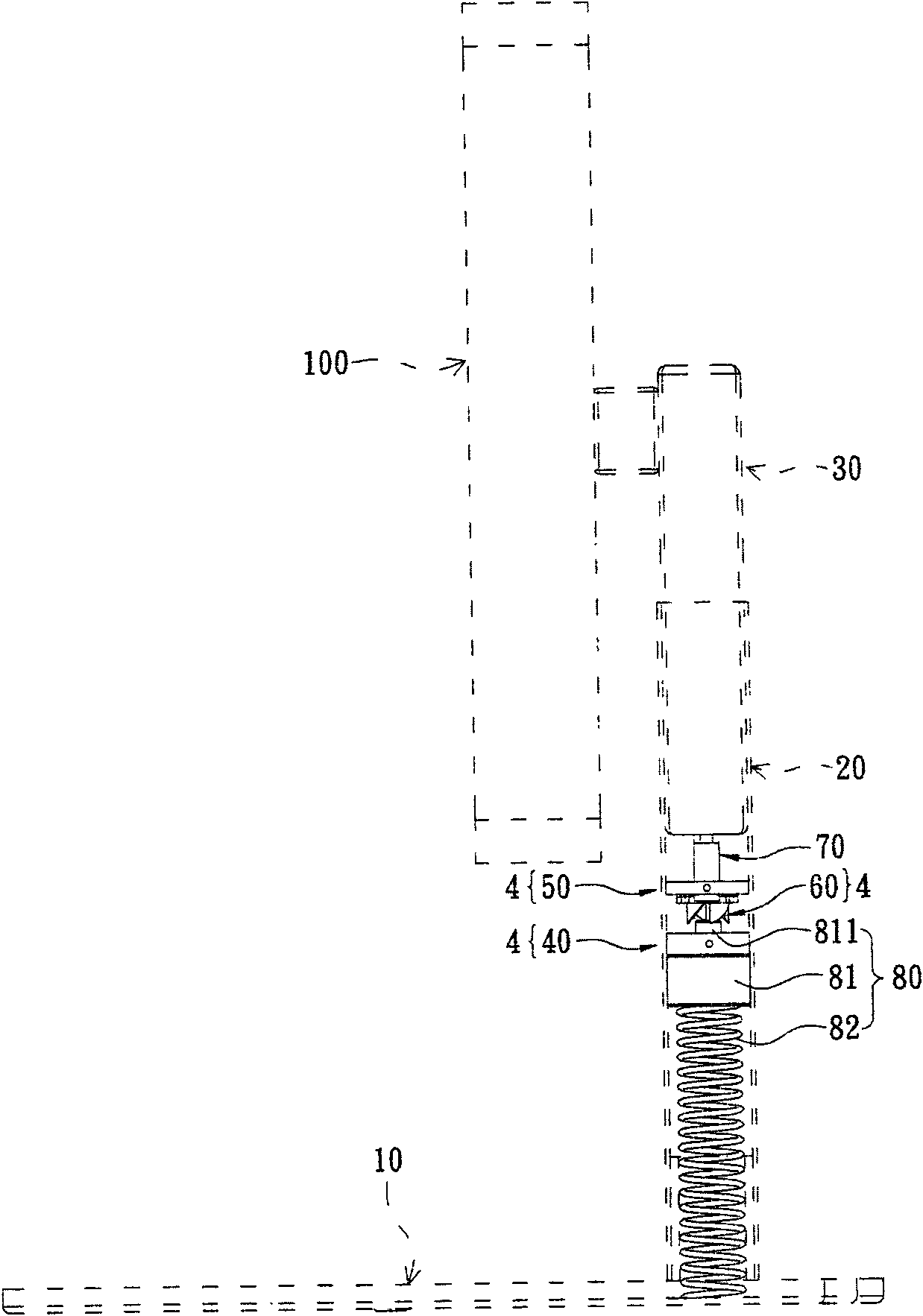

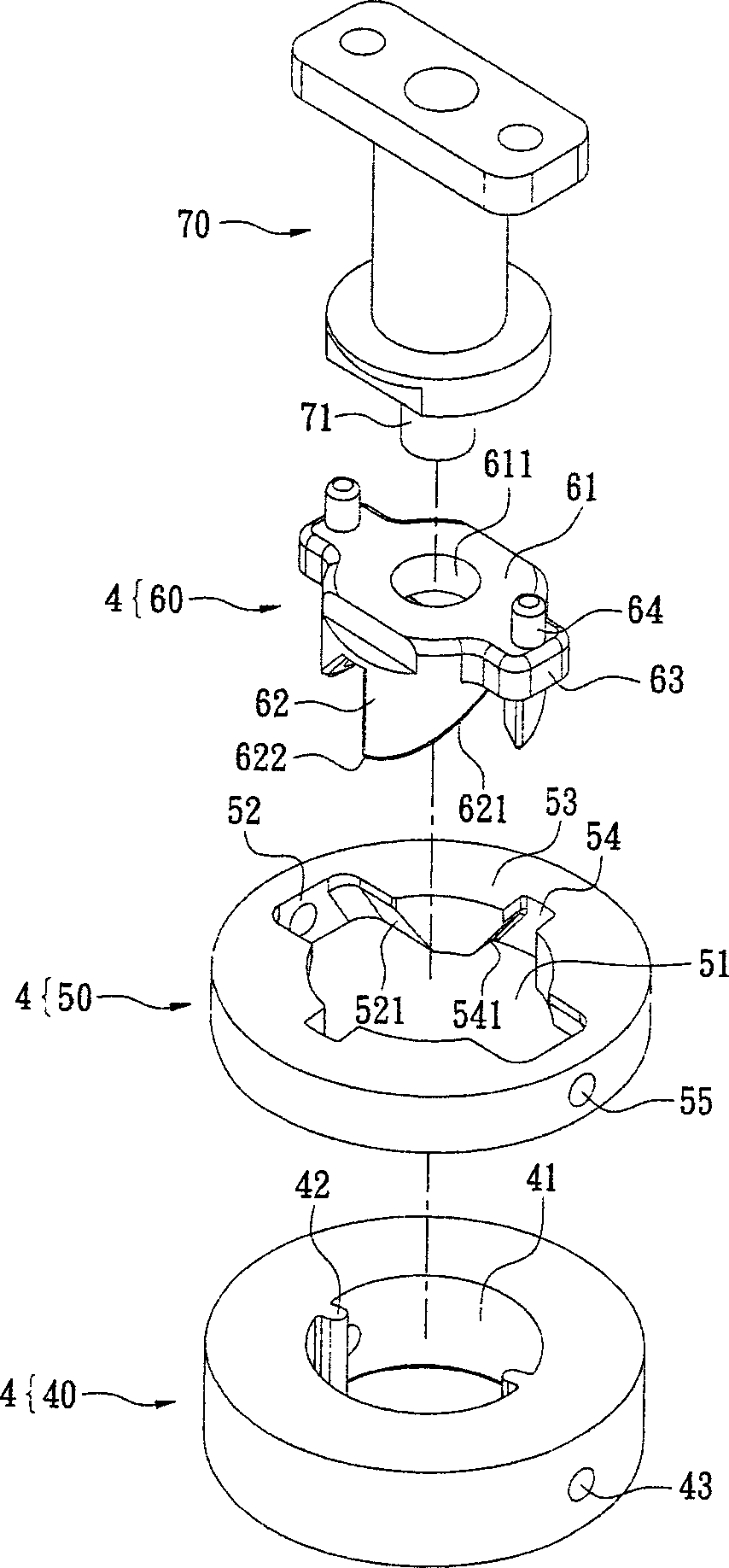

[0050] See figure 1 and figure 2 As shown, this embodiment provides a support frame, including: a base 10, a pillar 20, a moving part 30, and a latch structure 4. The pillar 20 is arranged on the base 10. The moving member 30 is disposed on the pillar 20 and can move relative to the pillar 20 along the up and down direction. The moving part 30 can be assembled on the rear side of a display 100 through other components. In addition, usually the support frame is provided with a certain force elastic member (not shown in the figure) between the pillar 20 and the moving member 30, such as a known coil-type constant force spring, to constantly apply an upward direction to the moving member 30 The force is applied so that the display 100 can move up and down relative to the pillar 20 through the movable member 30 and be positioned at a desired position. Since the structure of the above-mentioned constant-force elastic member is not the focus of the discussion in this case, it is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com