Pressure reduction mechanism for air distribution cam shaft of diesel engine

A technology of decompression mechanism and camshaft, which is applied to machines/engines, mechanical equipment, engine components, etc., can solve the problems of insufficient intake air, difficulty in starting the diesel engine, affecting the air compression effect, etc., and achieves elimination of exhaust valve clearance, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

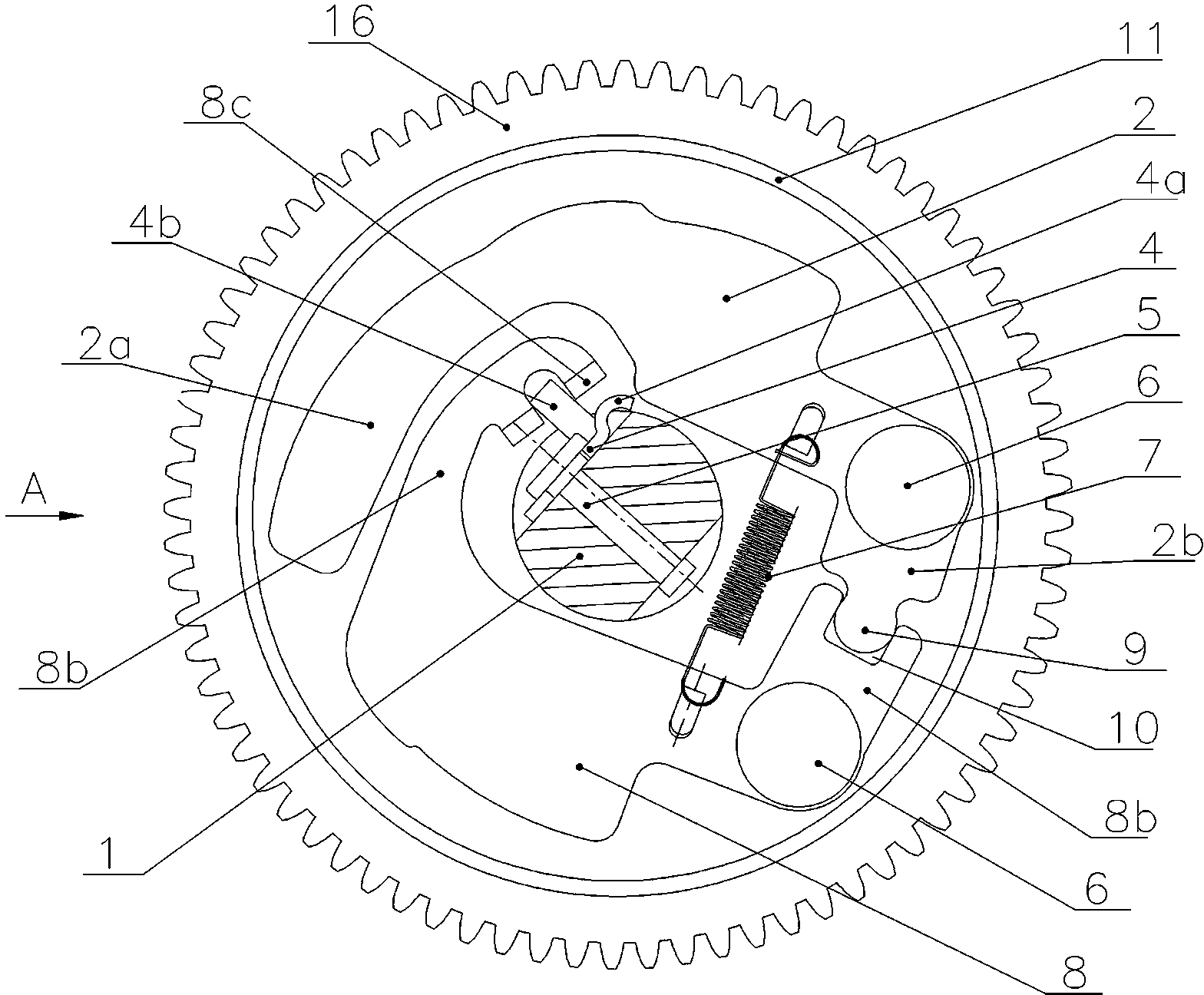

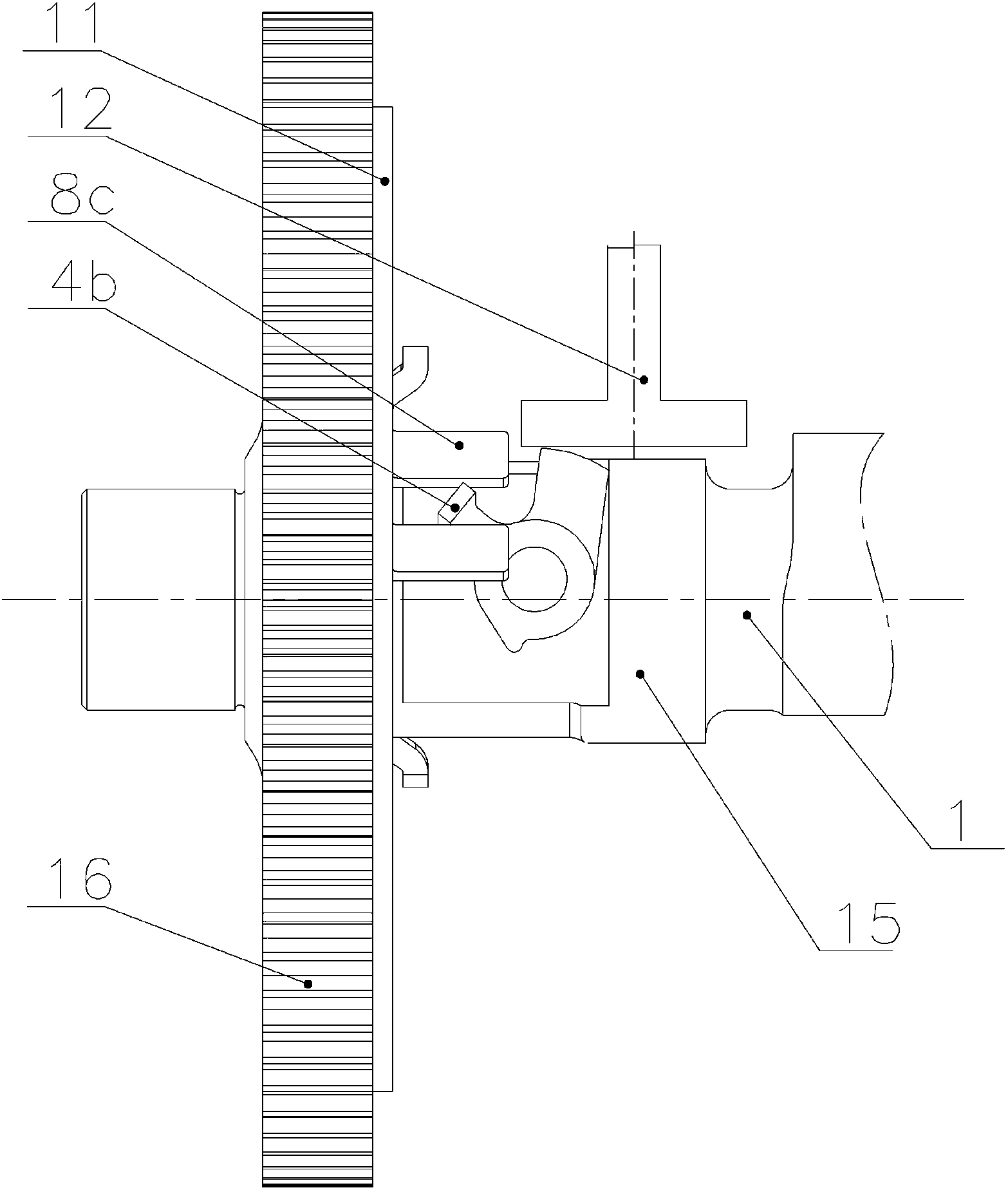

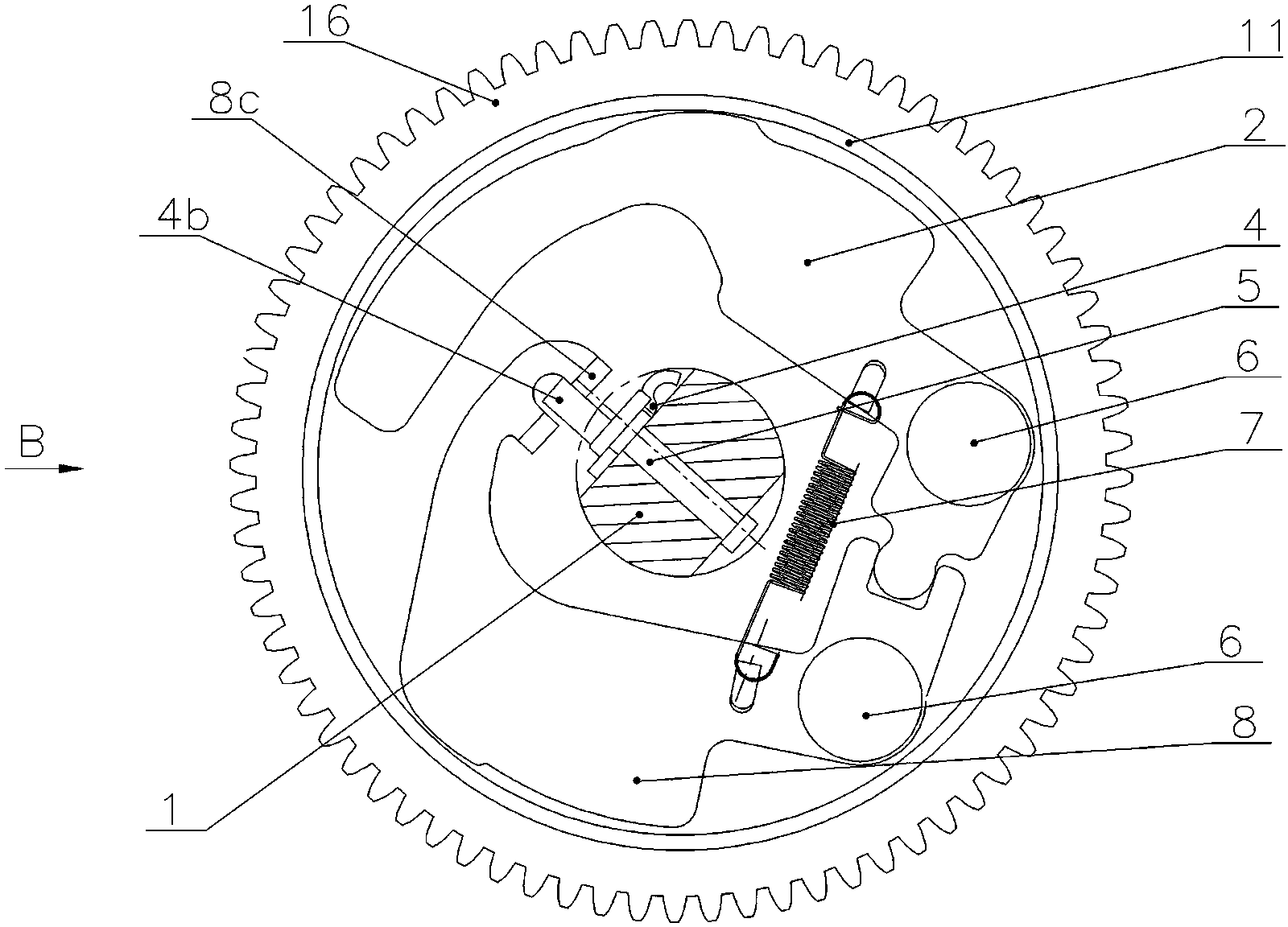

[0024] see Figure 1 to Figure 4, the decompression mechanism of the gas distribution camshaft of the diesel engine. The gas distribution camshaft 1 of the diesel engine is provided with intake and exhaust cams, and a timing gear 16 is fixed on the camshaft 1. The pressure block 4 and the decompression block 4 are located beside the exhaust cam 15 . The decompression block 4 includes a decompression support portion 4a and a lever portion 4b. An acute-angled angle is formed between the decompression support portion 4a and the lever portion 4b of the decompression block 4, and the angle of the acute-angled angle is 60°. ~80°, preferably 65°. The corner between the decompression support part 4a and the lever part 4b of the decompression block 4 is hinged with the camshaft 1 through a pivot pin 5, and the camshaft 1 is provided with a tangent plane on the shaft section of the decompression block 4, and the exhaust cam The axial end adjacent to the base circle portion of 15 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com