Foam drainage gas recovery method for natural gas horizontal well

A foam drainage and natural gas technology, applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve problems such as undiscovered ideas, products, process design methods and theoretical basis research, and achieves wide application range and simple operation Safe and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

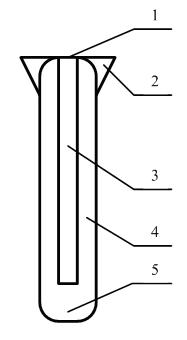

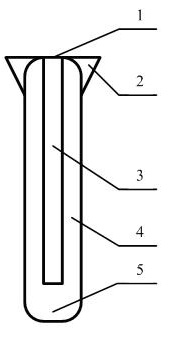

[0012] The present invention will be further described in conjunction with accompanying drawings.

[0013] refer to figure 1 . The downhole power bubble row rod is composed of an air nozzle 1, an empennage 2, a booster 3, a casing 4, and a protective headgear 5. The booster 3 is wrapped with a shell 4, the bottom of the tail end of the shell 4 is provided with an air jet 1, four tail fins 2 are installed outside the tail end of the shell 4, and a protective headgear 5 is installed on the head of the shell 4. The material for making the empennage 2, the housing 4 and the protective headgear 5 is a solid foaming agent, and the solid foaming agent is composed of polyoxyethylene alkyl ether, polyethylene glycol, urea, imidazoline, dodecylbenzenesulfonic acid Sodium and saturated alcohol sulfates. Wherein, the mass percentage of polyoxyethylene alkyl ether is 15%, the mass percentage of polyethylene glycol is 12%, the mass percentage of urea is 3%, the mass percentage of imidazo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com