Construction method for PVC (poly vinyl chloride) drainage direct-buried pipe fitting

A technology of directly buried pipes and pipe fittings, which is applied in the direction of construction, building structure, and building materials processing. It can solve the problems of high installation cost, low construction efficiency, and easy water seepage, so as to improve construction efficiency, improve construction efficiency, The effect of reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

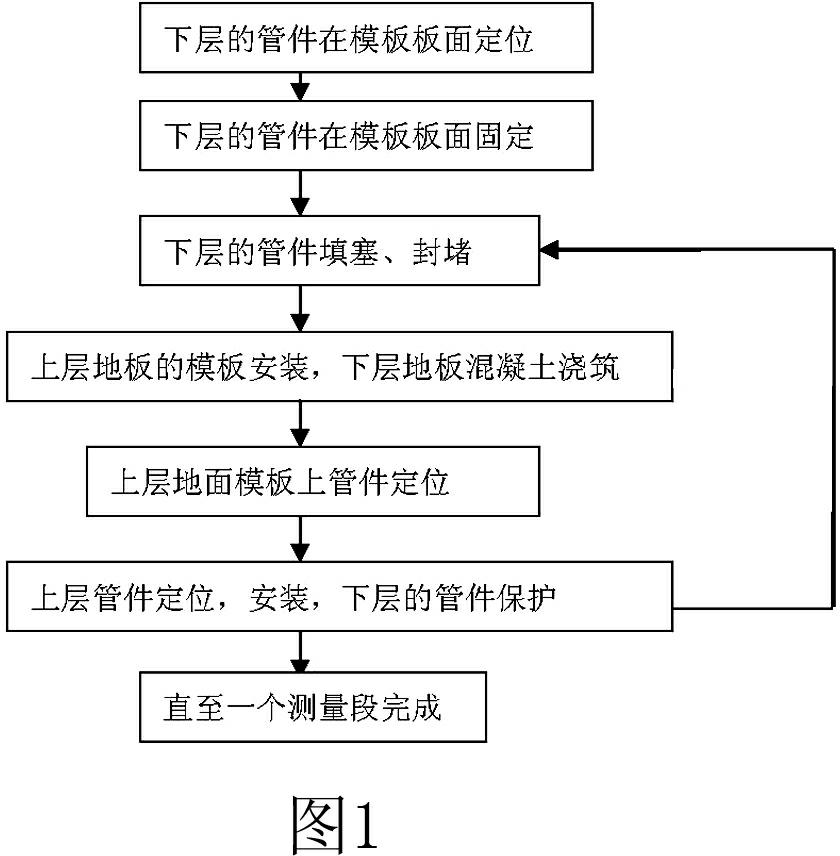

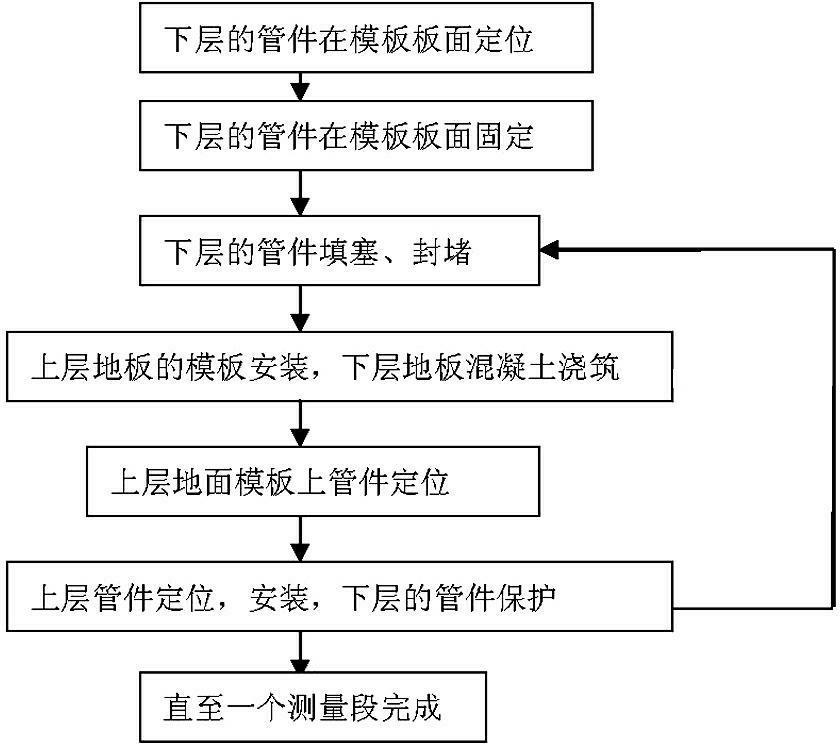

[0029] Examples see figure 1 Shown, a kind of PVC drainage directly buried pipe fitting construction method is characterized in that: comprises the following steps:

[0030] Step 1: Divide the whole building into several measurement sections according to the height of the building; each measurement section has 4 to 5 floors

[0031] Step 2, supporting the ground formwork on the lower floor of the first measurement section;

[0032] Step 3: According to the construction drawings, refer to the axis of the slab surface and the measurement control line, supplemented by the center line of the beam, locate the center coordinates of each pipe fitting on the lower ground formwork of the first measurement section, determine the installation position of the pipe fittings, and install the pipe fittings with screws Go to the lower ground formwork of the first measurement section; use the center coordinates as the origin, take the outer diameter of the pipe fittings to be installed as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com