Pinhole type chain extension reactor for spandex elastic fiber

An elastic fiber and reactor technology, used in the field of liquid and liquid mixing and chain extension, can solve the problems of batch-to-batch product quality differences, low chain extension reaction efficiency, and high labor intensity, so as to ensure product quality and improve chain extension reactions. Efficiency, the effect of continuous conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

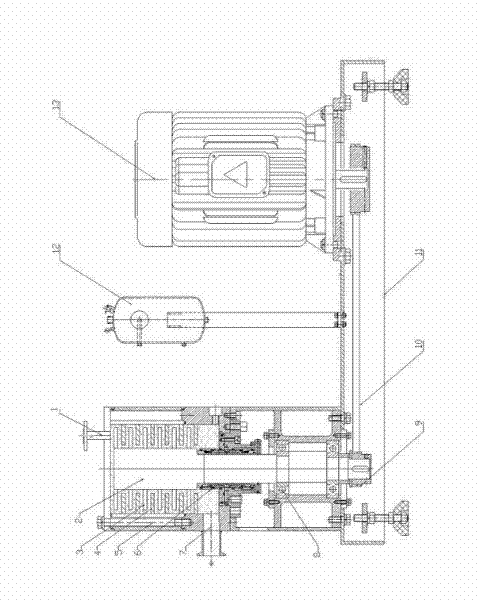

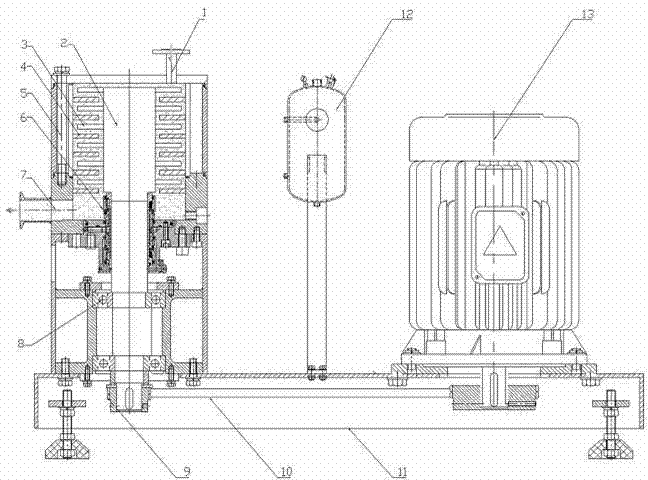

[0014] figure 2 It is a spandex elastic fiber pin-type chain extension reactor of the present invention. As shown in the figure, the fiber pin-type chain extension reactor is mainly composed of a main body inlet and outlet 1, a main shaft 2, a bearing seat 8, a pin rotor 3, Pin stator 4, shaft end mechanical seal 6, base 11, belt 10, motor 13; body inlet 1, main shaft 2, pin rotor 3, pin stator 4, body jacket 5, body outlet 7 constitutes the working chamber of the extended chain reactor; the pin rotor 3 is installed on the main shaft 2, and the pulley 9 is installed on the other end of the main shaft 2; the mechanical seal 6 at the shaft end acts as a shaft seal to prevent air from entering and material from leaking out; the bearing seat 8 is used to support , positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com