Treatment method for realizing rapid resource treatment and zero emission of vegetable waste

A technology of vegetable waste and processing method, which is applied in the field of rapid resource and zero-emission treatment of vegetable waste, can solve the problems of waste, secondary pollution of resources, etc., achieves small nutrient loss, small nutrient loss, improved quality and quick effect The effect of small molecule organic nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

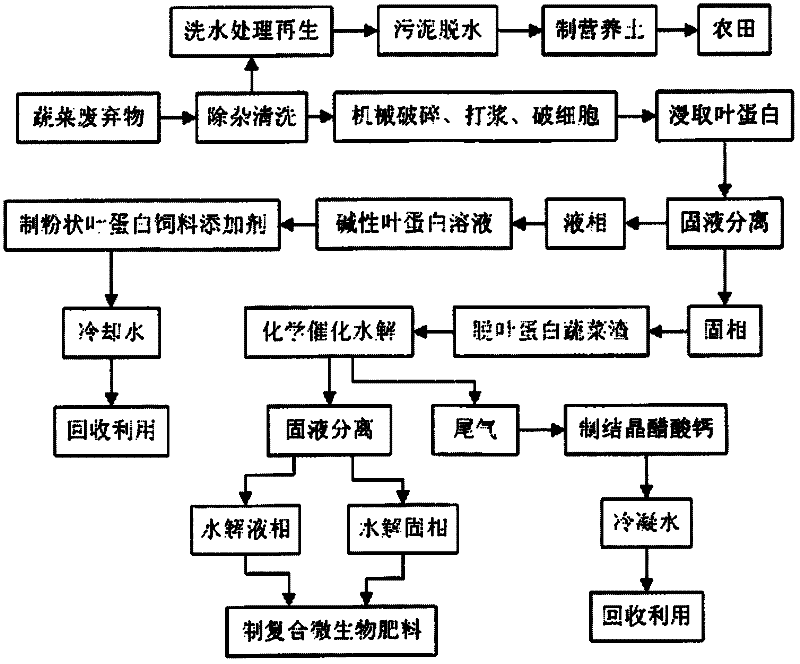

[0032] Further illustrate the present invention below in conjunction with accompanying drawing.

[0033] Such as figure 1 As shown, the processing method of vegetable waste quick recycling and zero discharge of the present invention comprises the following steps:

[0034] 1) Impurity removal: first use a vibrating sieving machine to remove the sediment on the surface of the vegetable waste, and then use a mixture of water and compressed air 5 times the volume of the vegetable waste in a water tank with an automatic transmission stainless steel mesh belt. After the vegetable waste is washed, drained and dehydrated by a rolling machine, the gas-water volume ratio in the mixture is 1:1, and the cleaning water is treated according to conventional water to produce regenerated water for recycling of the whole set of equipment, and the dewatered sludge is used as nutrient soil. return to farmland;

[0035] 2) Mechanical crushing, beating, and cell wall breaking: use a scissor crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com