Additive for crack self-repairing cement-base material, use method thereof and cement-base material

A technology of cement-based materials and additives, which is applied in the field of cement-based materials and self-repairing additives for cracks in cement-based materials. It can solve the problems of inconvenient mixing of concrete, lack of self-regulation and self-repair, and inability to ensure uniform distribution of concrete structures. Effect of Labor Repair Funding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Bacterial culture

[0026] Prepare the culture medium (the composition of the medium is shown in Table 1), adjust the pH = 7.0, sterilize at 121°C for 25 minutes, dry in an oven at 60°C, and inoculate the strain Bacillus halodurans into the Erlenmeyer flask containing the medium ( Aseptic operation), shaking culture at 30°C (oscillating frequency 170r / min) for 24h on a shaking table to obtain a turbid bacterial liquid, the concentration of the bacterial cells contained in the bacterial liquid is (5~6)×10 6 individual / mL. The bacterial liquid was placed in a centrifuge at 7000r / min for 5 minutes, and the bacterial sludge was obtained by freezing and centrifuging.

[0027] Table 1 Medium composition

[0028]

[0029] Selection of carrier

[0030] As a necessary condition for the self-healing of cracks, the carrier mainly plays the role of adsorbing microorganisms and giving them enough space to survive, and the selected slag and ceramsite are both porous. The parti...

Embodiment 2

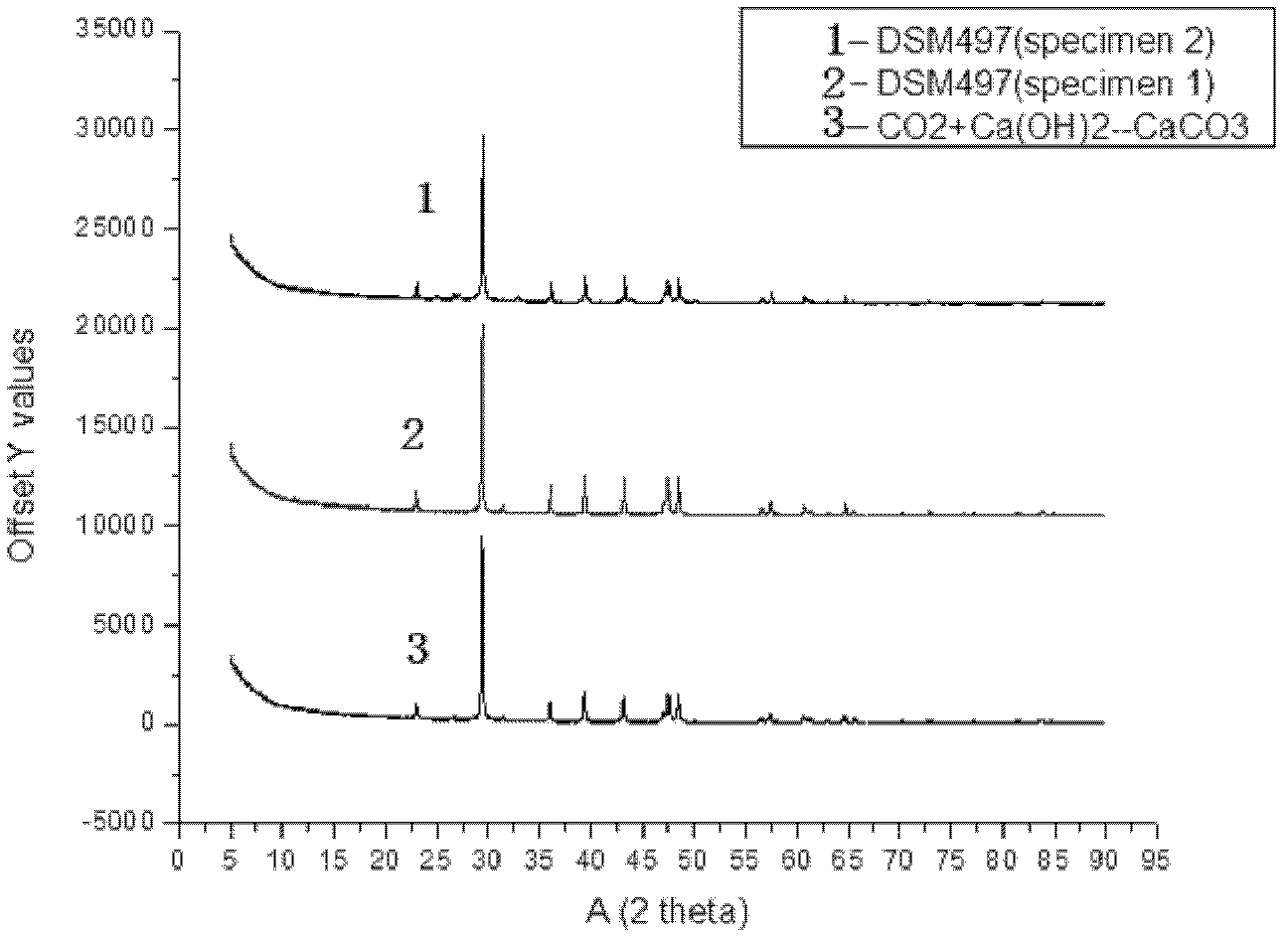

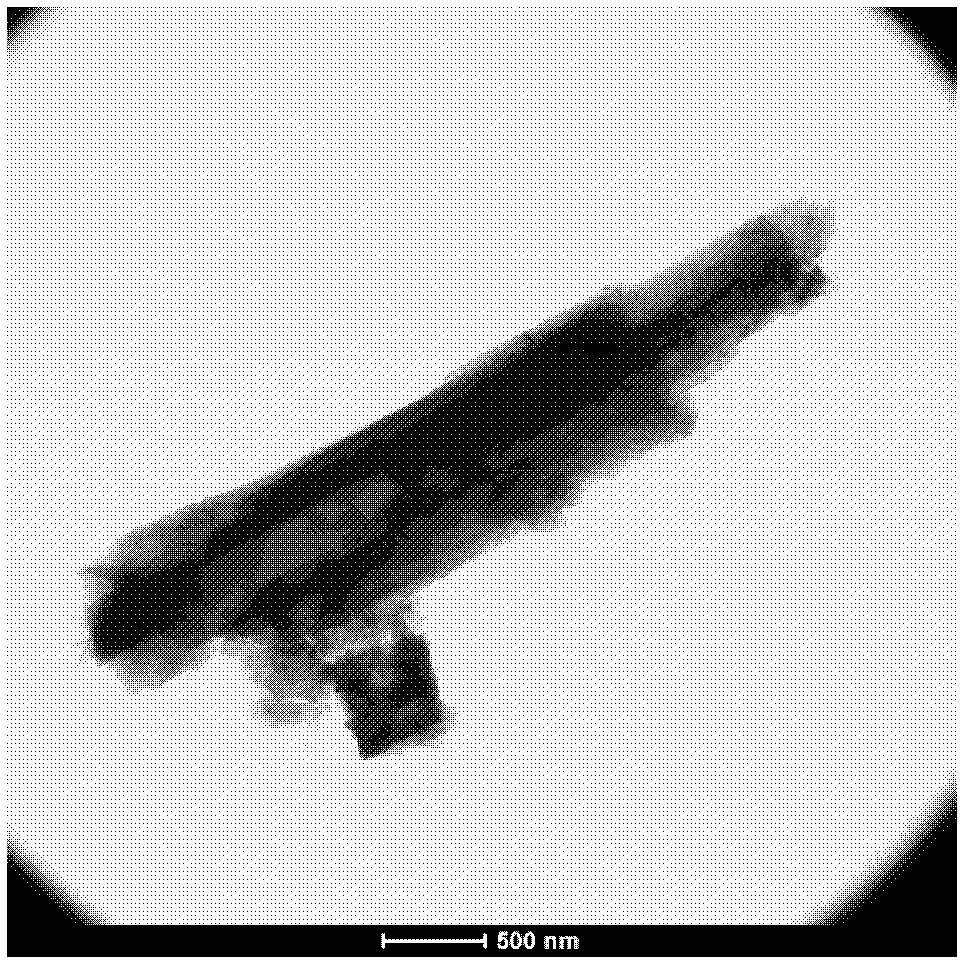

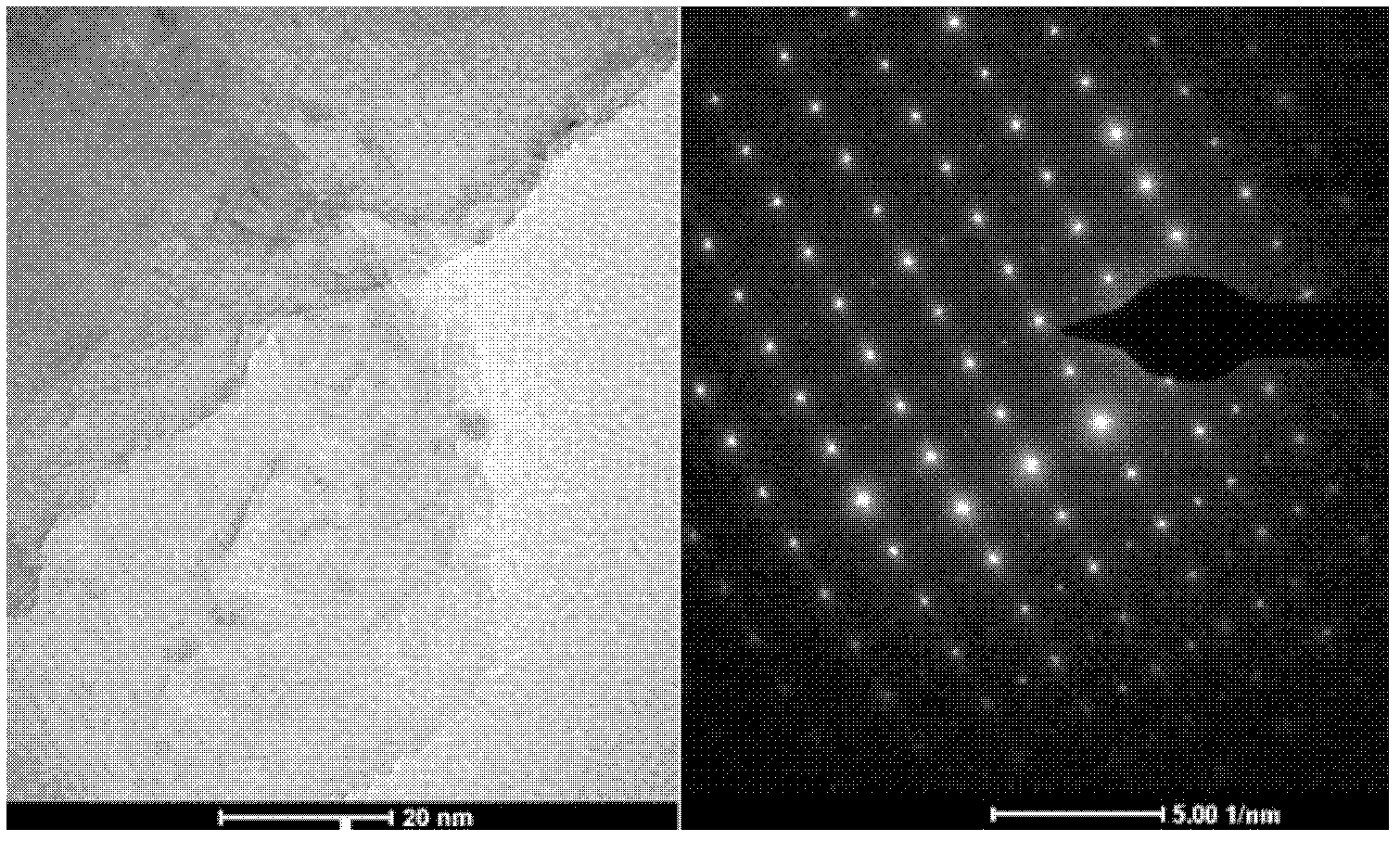

[0044] According to the mixing ratio shown in Table 3, at the same time, each group was mixed with 100 mL of bacterial sludge obtained by centrifuging the bacterial liquid to form a mortar sample. Cured for 7 days in a standard curing room to obtain the concrete material of the present invention, manufactured cracks according to the method of Example 1, and then repaired, calcium carbonate precipitates could be obviously formed in the cracks in 5 days, and a layer of compact concrete could be formed after 40 days It proves that the cement-based material of the present invention does have self-healing function.

[0045] Table 2 Mortar sample molding mix ratio

[0046]

[0047] The calcium lactate is formulated as a 1%wt aqueous solution for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com