Internal-expansion sealing cover for round-mouth cans

A technology of inward expansion and round mouth, which is applied in the direction of anti-rot containers, closures, containers, etc. It can solve the problems of poor sealing effect and outdated sealing method, and achieve good effect and novel sealing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described now in conjunction with accompanying drawing,

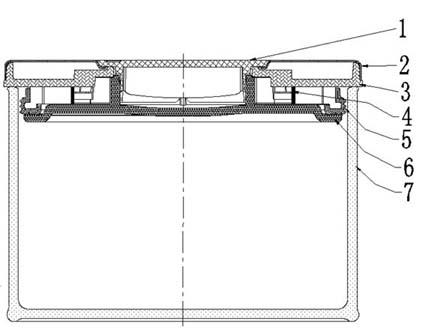

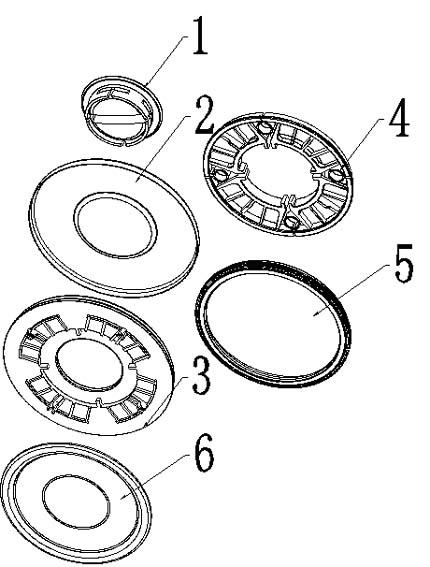

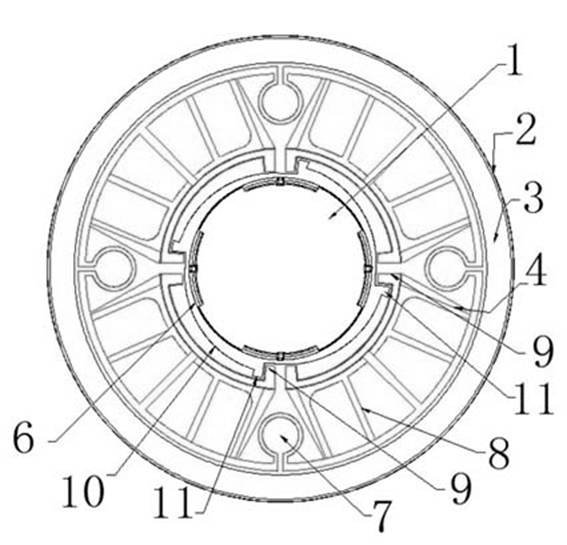

[0012] An internal expansion sealing cover for round-mouthed tanks, consisting of a stainless steel outer cover 2 covering the outer edge of the tank mouth and an inner cover 6 that acts as a seal; The knob 1, the inner cover 6 are combined with the inner cover lining 3 with the knob clamping position; its composition is: a circular expansion hoop 4 is embedded in the inner cover, and the circular expansion hoop is composed of four quarters The expansion hoop is connected by an open elastic circle 7. The expansion hoop is composed of a quarter circle with a large diameter and a quarter circle with a corresponding small diameter. It is composed of five straight ribs 8 connected. The circle is attached to the involute surface 10 that gradually changes from the narrow surface to the wide surface with the limit gear 9 at both ends; the top column 11 connected with the knob 1 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com