Rolling surface adhesive object scraping device for battery pole piece rolling machine

A battery pole piece and scraping device technology, which is applied to cleaning methods and utensils, cleaning methods using tools, and keeping roller equipment in an effective state, etc. Human resources and other issues, to avoid inadequate manual cleaning, ensure rolling quality, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

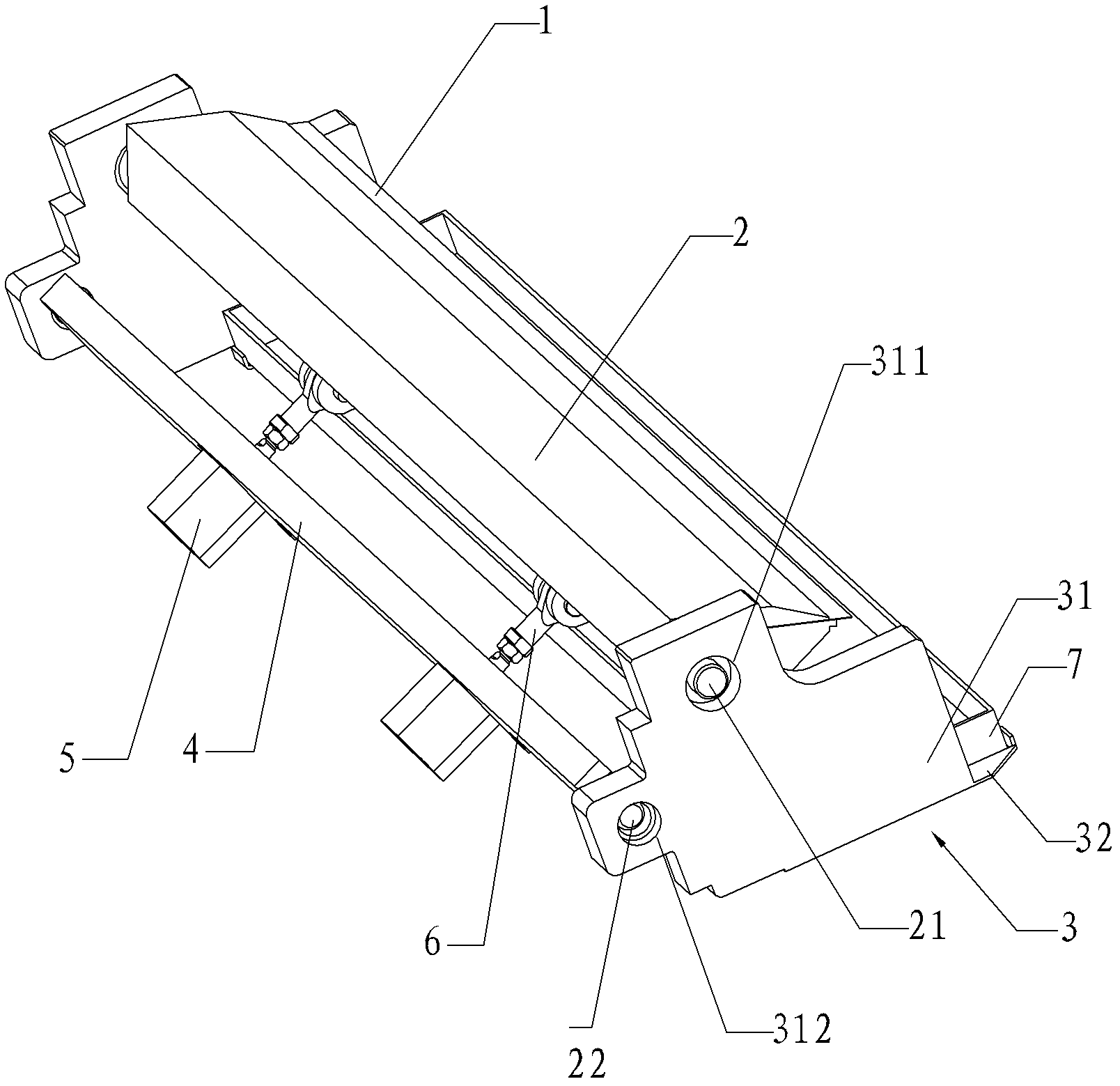

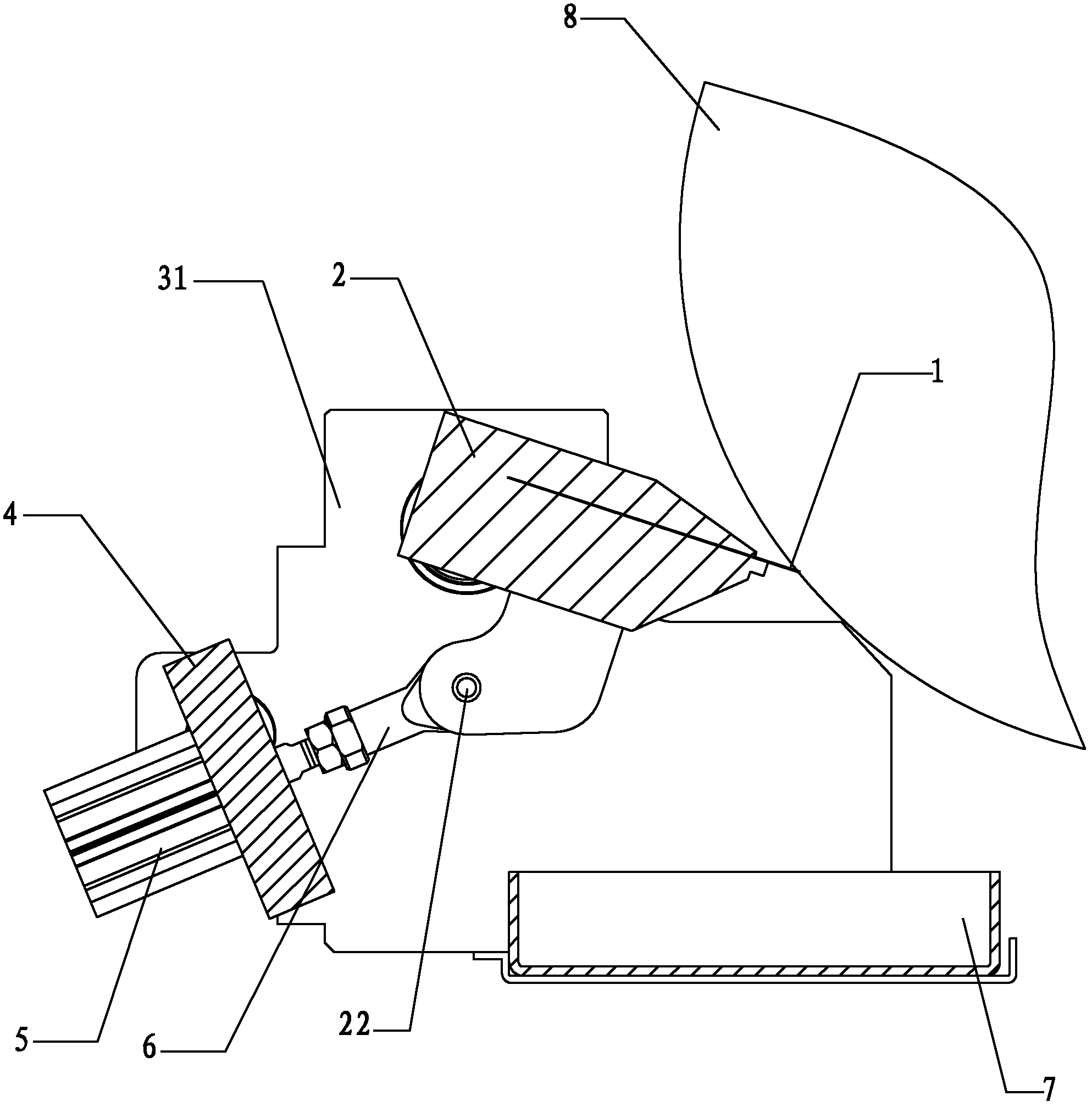

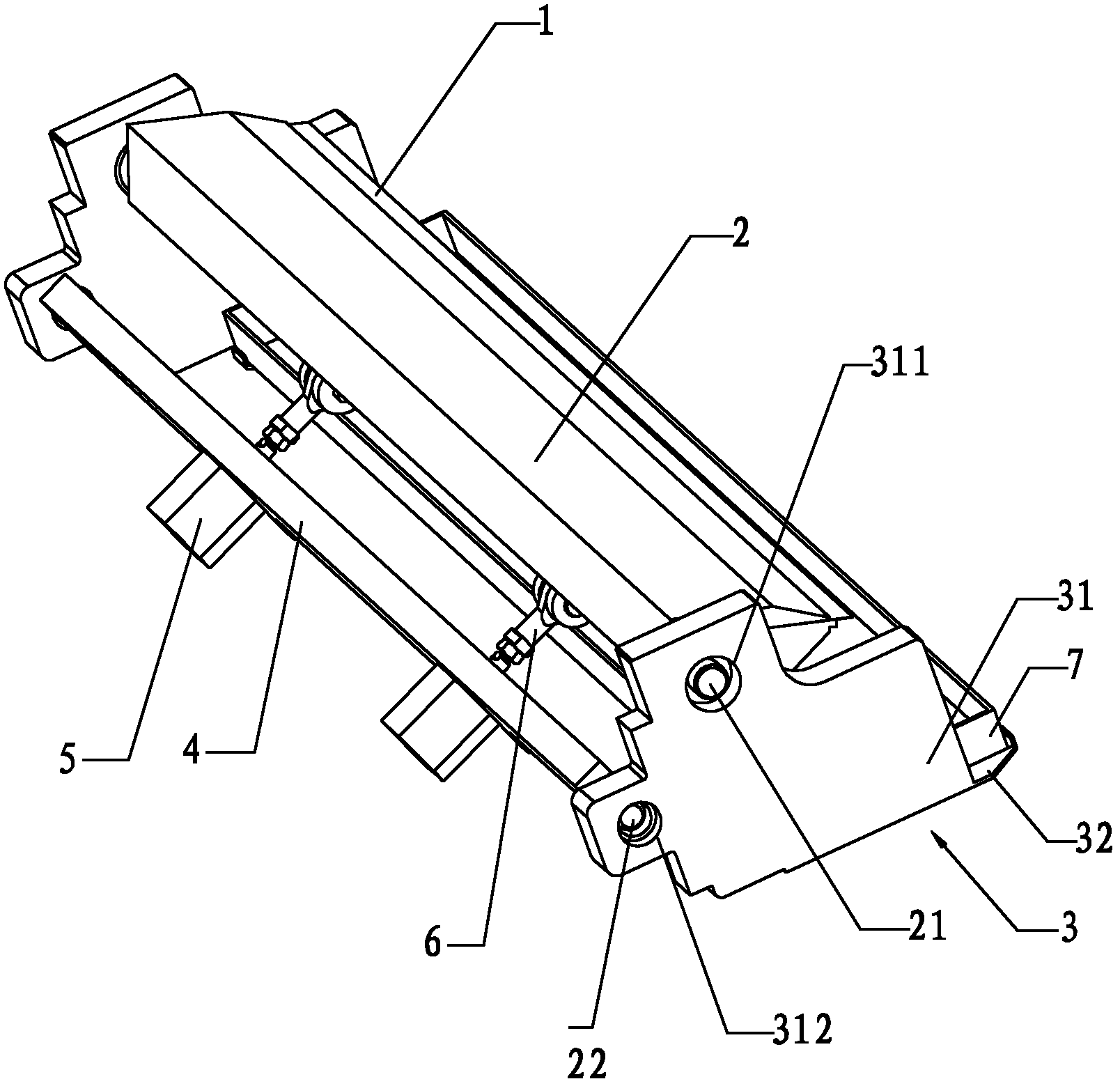

[0019] Reference attached figure 1 And attached figure 2 , The present invention provides an embodiment of a device for scraping adhesions on the roller surface of a battery pole piece rolling machine, including a fixed support 3, a blade holder 2, a blade 1, a power cylinder 5, and a power cylinder holder 4;

[0020] The fixed support 3 includes two parallel side walls 31 and a connecting plate 32 connecting the two side walls 31. The blade 1 is arranged on the blade fixing frame 2, and the blade fixing frame 2 is provided with first pins on both sides 21. The two side walls 31 are provided with first rotating holes 311 adapted to the first pin shaft 21, and the blade holder 2 is rotatably arranged on the fixed support through the cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com