Automatic scale-cleaning shower head

A self-cleaning and shower technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of cleaning, time-consuming and laborious cleaning, and blocked water outlets, etc., and achieve the effect of safe and convenient use, simple and compact structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

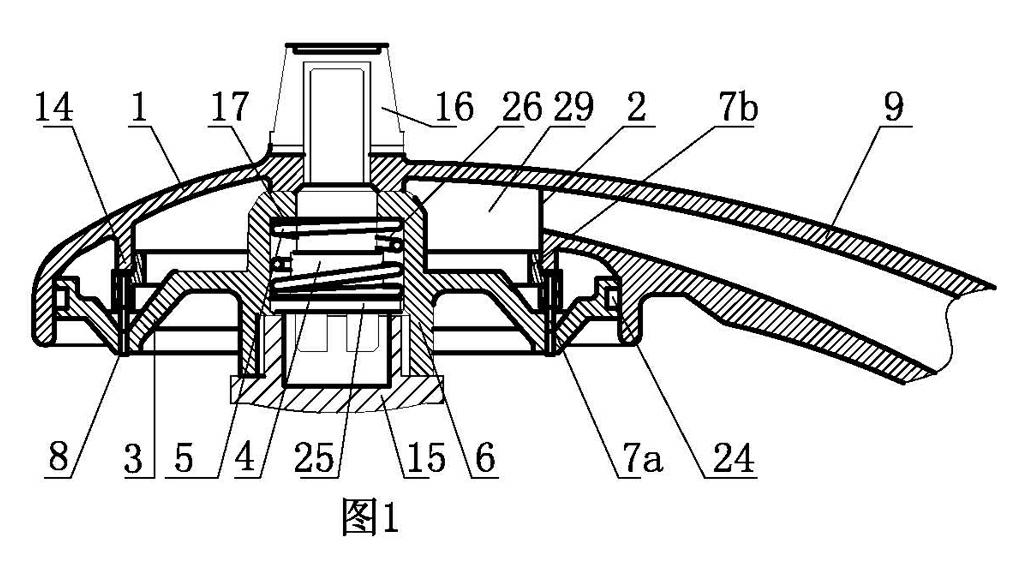

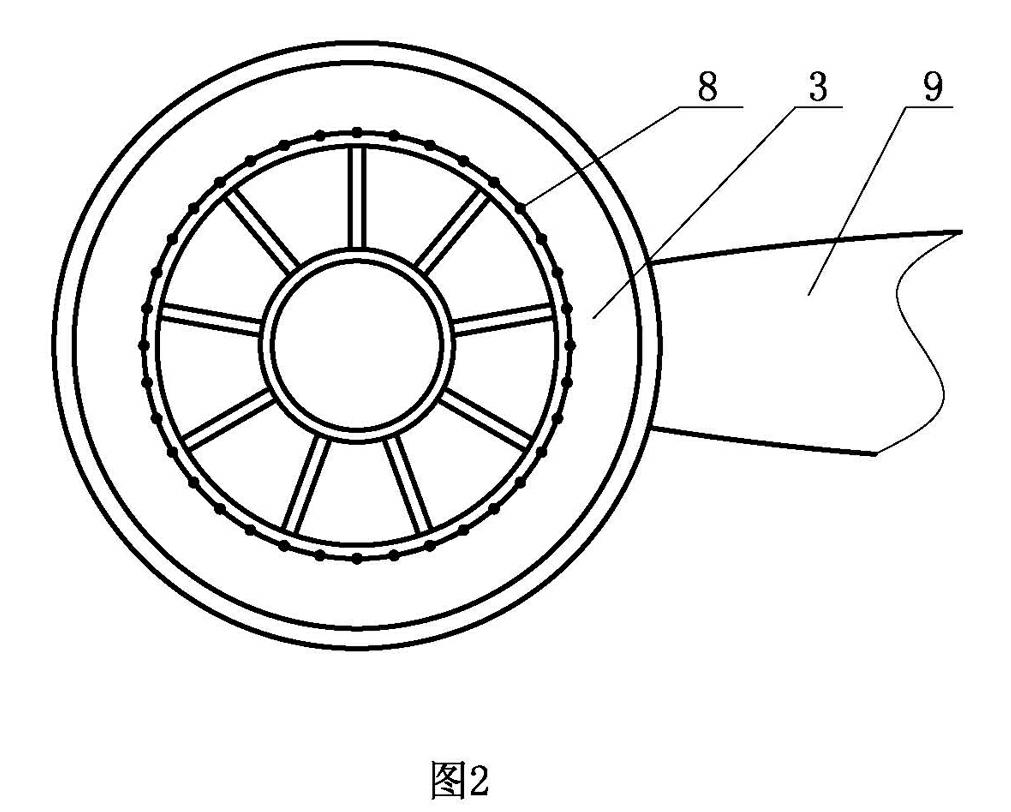

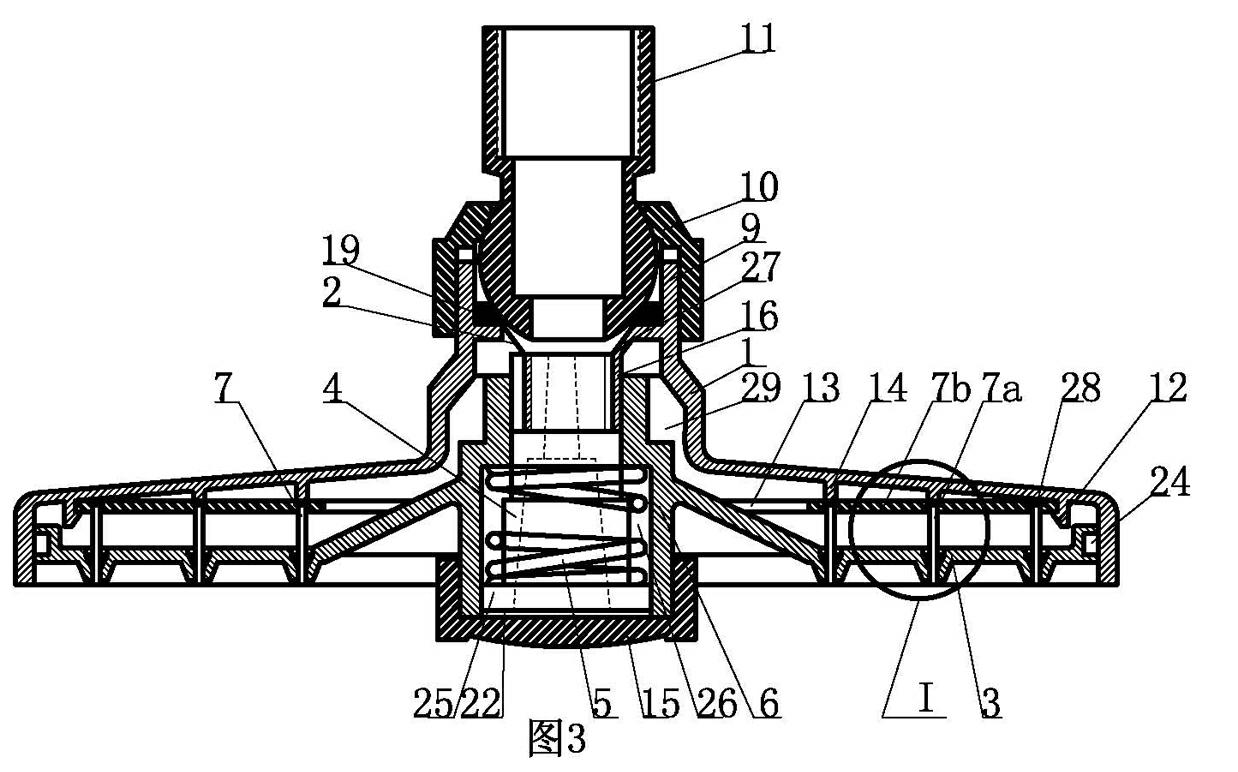

[0009] The self-cleaning shower head of the present invention comprises a housing 1, on which a water inlet 2 is opened, and the water inlet 2 communicates with the water outlet pipe of the shower. The housing 1 is provided with a water chamber 29 , and the water inlet 2 communicates with the water chamber 29 . The guide post 4 is fixedly installed in the water cavity 29, and the guide post 4 is fixed with the housing 1. The outer periphery of guide post 4 is movable to install sliding sleeve 6, and sliding sleeve 6 can slide up and down along guide post 4 reciprocatingly. The outer periphery of the sliding sleeve 6 is provided with a moving plate 3 , and the outer periphery of the moving plate 3 cooperates with the housing 1 . Offer several water outlet holes 8 on the mobile plate 3, as figure 2 As shown, the water outlet holes 8 are usually distributed in a circle. Several descaling needles 7 are fixedly installed in the casing 1, and the descaling needles 7 and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com