Preparation method of penehyclidine hydrochloride powder injection for injecting

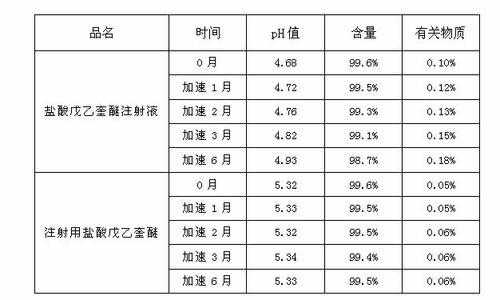

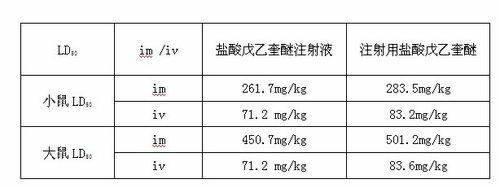

A technology of penehyclidine hydrochloride and powder injection, which is applied in the preparation of penehyclidine hydrochloride powder injection and the field of preparation of penehyclidine hydrochloride for injection, and can solve the problems of content decrease, pH value and related substance increase, etc. To achieve the effects of reducing the chance of contact, stabilizing related substances and content, and reducing the speed of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

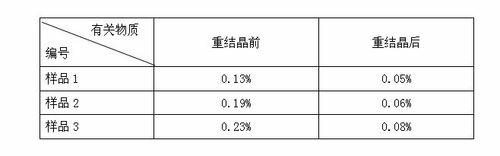

[0066] A. Take 100g of penehyclidine hydrochloride, add 600ml of anhydrous ethanol-anhydrous ether (1:2), heat to 78°C to dissolve, add 0.2g of activated carbon to stir, first decarburize with coarse filtration, and then use 0.22 The microporous membrane of μm is filtered to obtain a clear liquid;

[0067] B. Under a sterile environment, recrystallize the clear liquid in step B, filter under reduced pressure, wash with 300ml of absolute ethanol-anhydrous ether (1:2), drain, dry at 105°C, and pulverize to obtain pentyl hydrochloride Diethylquilidine sterile powder, ready for use after packaging;

[0068] C, the preparation of penehyclidine hydrochloride powder injection for injection

[0069] a. Glass bottle treatment: Clean the glass bottle with ultrasonic waves, rinse it with pure water, then rinse it with water for injection, and sterilize it with tunnel-type dry heat at 320°C for 5 minutes to obtain a clean, sterile, dry, heat-free glass bottle;

[0070] b. Treatment of r...

Embodiment 2

[0073] A. Take 100g of penehyclidine hydrochloride, add 700ml of anhydrous ethanol-anhydrous ether (1:2), heat to 75°C to dissolve, add 0.3g of activated carbon to stir, first decarburize by coarse filtration, and then use 0.22 The microporous membrane of μm is filtered to obtain a clear liquid;

[0074] B. Under a sterile environment, recrystallize the clear liquid in step B, filter under reduced pressure, wash with 300ml of absolute ethanol-anhydrous ether (1:2), drain, dry at 105°C, and pulverize to obtain pentyl hydrochloride Diethylquilidine sterile powder, ready for use after packaging;

[0075] C, the preparation of penehyclidine hydrochloride powder injection for injection

[0076] a. Glass bottle treatment: Clean the glass bottle with ultrasonic waves, rinse it with pure water, then rinse it with water for injection, and sterilize it at 180°C for 1.5 hours to obtain a clean, sterile, dry, heat-free glass bottle;

[0077] b. Treatment of rubber stoppers: wash the rub...

Embodiment 3

[0080] A. Take 100g of penehyclidine hydrochloride, add 100ml of anhydrous ethanol-anhydrous ether (1:10), heat to 40°C to dissolve, add 0.2g of activated carbon for injection and stir, first decarburize by coarse filtration, and then use 0.22 The microporous membrane of μm is filtered to obtain a clear liquid;

[0081] B. Under a sterile environment, recrystallize the clear liquid in step B, filter under reduced pressure, wash with 400ml of absolute ethanol-anhydrous ether (1:10), drain, dry at 105°C, and pulverize to obtain pentyl hydrochloride Diethylquilidine sterile powder, ready for use after packaging;

[0082] C, the preparation of penehyclidine hydrochloride powder injection for injection

[0083] a. Glass bottle treatment: Clean the glass bottle with ultrasonic waves, rinse it with pure water, then rinse it with water for injection, and sterilize it with tunnel-type dry heat at 320°C for 5 minutes to obtain a clean, sterile, dry, heat-free glass bottle;

[0084] b....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com