Trackless drawer-type compact shelf

A technology of drawer-type compact shelves, which is applied in cabinets for storing books, household appliances, applications, etc., can solve problems such as difficulty in on-site installation, troublesome relocation of compact shelves, and tipping of the shelf body, so as to avoid the danger of tipping, relocation or adjustment The effect of convenient location and reduced handling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

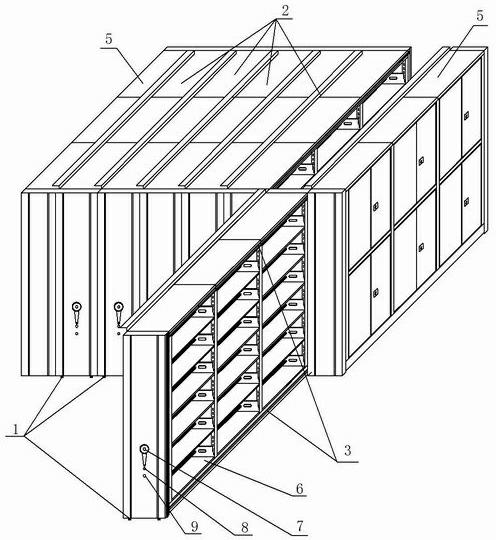

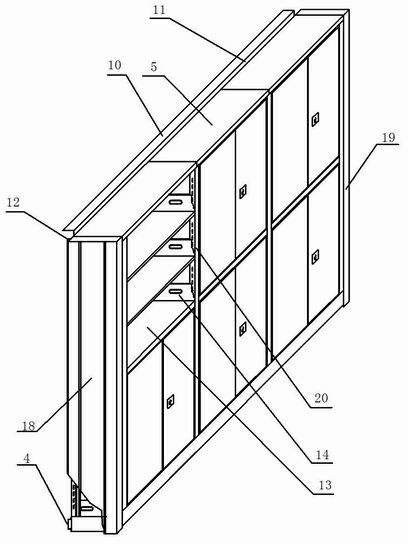

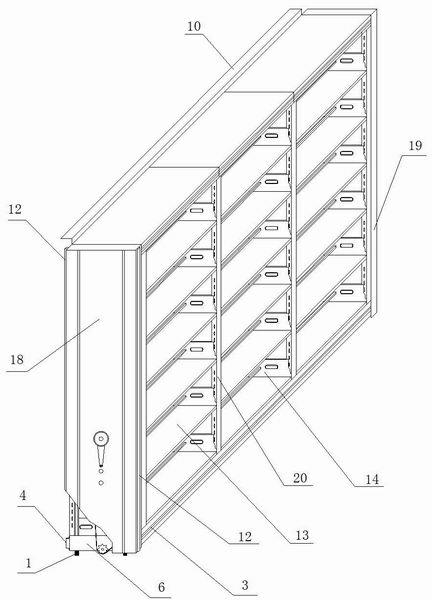

[0010] A trackless drawer-type compact shelf, which is composed of fixed column bodies 5 at both ends and a middle drawer-type frame body 2. The drawer-type frame body 2 includes a supporting plate 13, a hanging plate 14, a front panel 18, a rear panel 19 and a column 20. It is characterized in that a transmission system is set on the drawer-type frame body 2, and the hand crank 7, sprocket wheel 16 and chain 17 in the transmission system are installed on the connecting plate 15 at one end of the front panel 18 of the frame body, and the connecting plate 15 is also equipped with Safety lock 8 and safety locking mechanism 9, hand crank 7 link to each other with bevel gear set 21 on the frame body chassis 6 through sprocket wheel 16, chain 17, and bevel gear set 21 drives transmission shaft 23 on the chassis 6, rubber The wheel shaft 24 and the rubber wheel 1 move, and the rubber wheel 1 is mounted on the rubber wheel shaft 24 and fixed in the underframe 6 through the bearing 22;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com