Onboard efficient cotton cleaning device

A high-efficiency and cotton-cleaning technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of increasing the trash content, incomplete separation of seed cotton, and affecting the separation of fine trash, so as to improve the separation effect of fine trash, The effect of reducing the impurity content of seed cotton and enhancing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

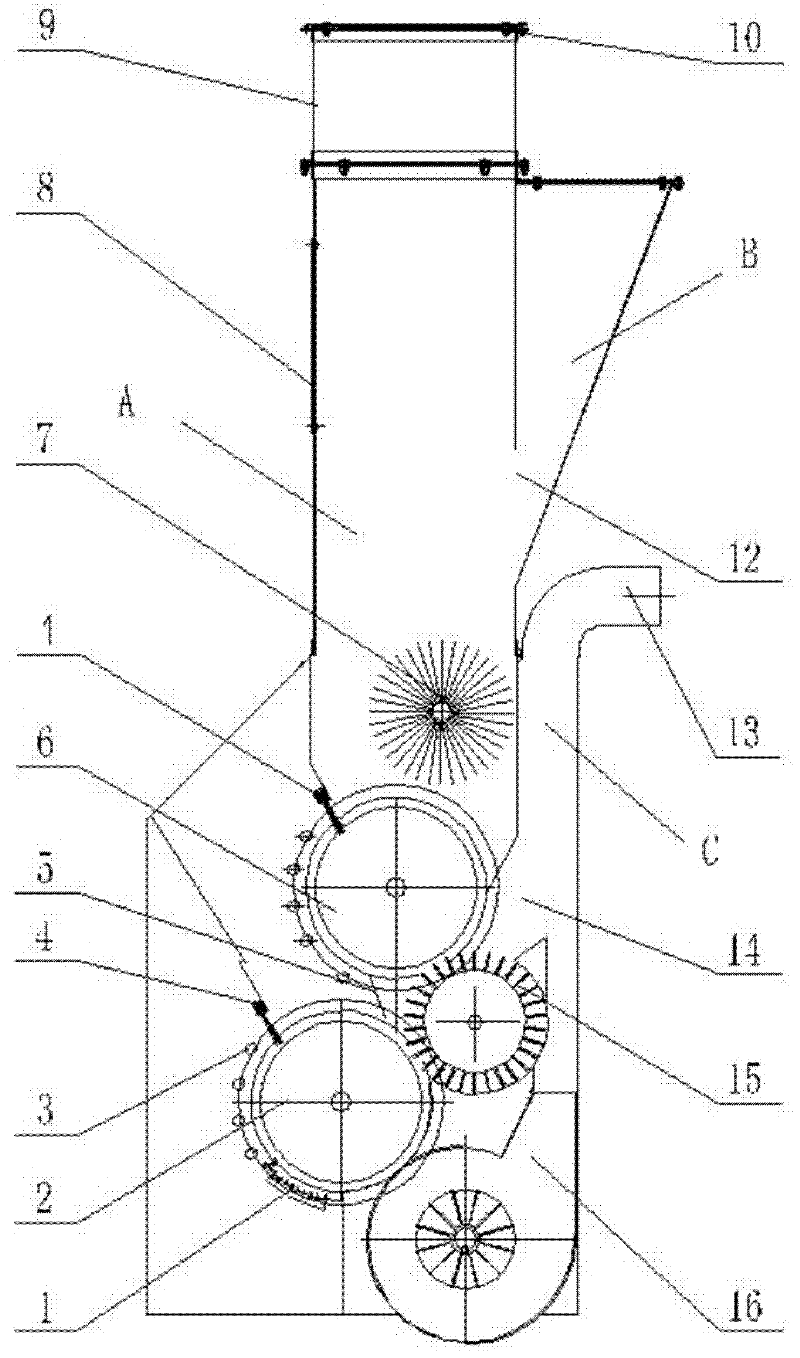

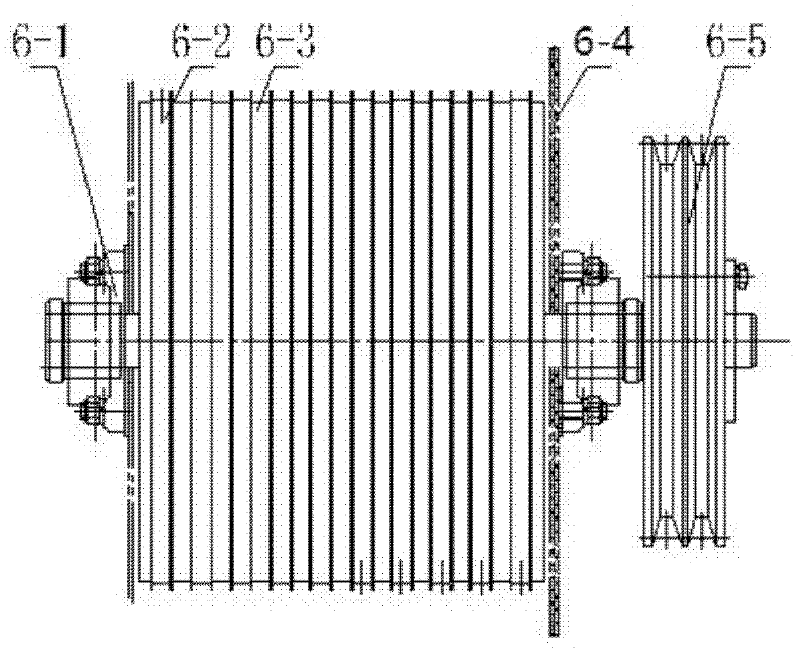

[0021] The basic structure of the airborne high-efficiency cleaning device of the present embodiment is as follows: figure 1 As shown, there is an input port 8 in the middle of one side of the vertical flow channel A at the top of the device, and the top of the vertical flow channel A is equipped with a honeycomb box 9 with honeycomb holes on the side wall, and the top of the honeycomb box 9 is equipped with a baffle. Cotton grid10. The lower part of the vertical flow channel A is equipped with parallel upper-stage toothed rollers 6 and lower-stage toothed rollers 2 supported in the lower casing. The upper brush and the lower brush 4 radially extending towards the upper toothed roller 6 and the lower toothed roller 2 are respectively installed on the lower end of the vertical channel A and the same side of the input port and the lower casing. Hairbrush 4 forms the inclination angle of about 60 ° (50 °-70 ° all can) with horizontal plane. On the side of the upper toothed roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com