Energy-saving double-circulation system of machine room

A circulation system and machine room technology, applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as redundant cooling capacity of equipment, different heat generation of equipment, and imperfect building insulation, etc., to achieve reduction Dispersion release, elimination of air circulation dead angle, elimination of transmission loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

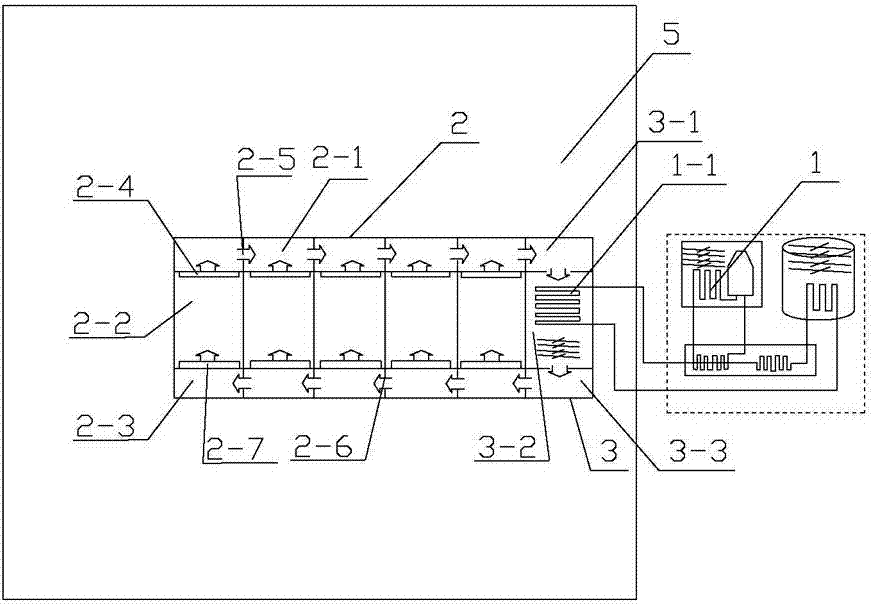

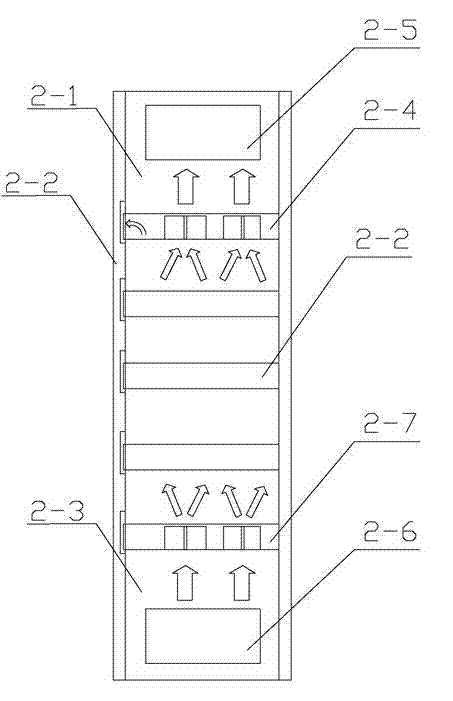

[0019] Embodiment 1: As shown in the figure, this kind of machine room energy-saving dual-cycle system includes a heat exchanger 1, a heat exchanger cabinet 3 and an energy-saving cabinet 2 arranged outside the computer room 5, and the energy-saving cabinet 2 Including cabinet upper air cavity 2-1, equipment installation unit 2-2, cabinet lower air cavity 2-3, temperature controlled exhaust unit 2-4 and temperature controlled air supply unit 2-7, said temperature controlled exhaust unit 2- 4 Including the main exhaust fan 2-4-1, at least one temperature-controlled exhaust outlet 2-4-2, maintenance air supply outlet A2-4-4, and the process associated with the temperature-controlled exhaust outlet 2-4-2 At least one air volume controller A2-4-3 for air volume control. The temperature-controlled air supply unit 2-7 includes a main blower 2-7-1, at least one temperature-controlled air supply port 2-7-2, a maintenance air supply port B2-7-4, and the temperature-controlled air supply...

Embodiment 2

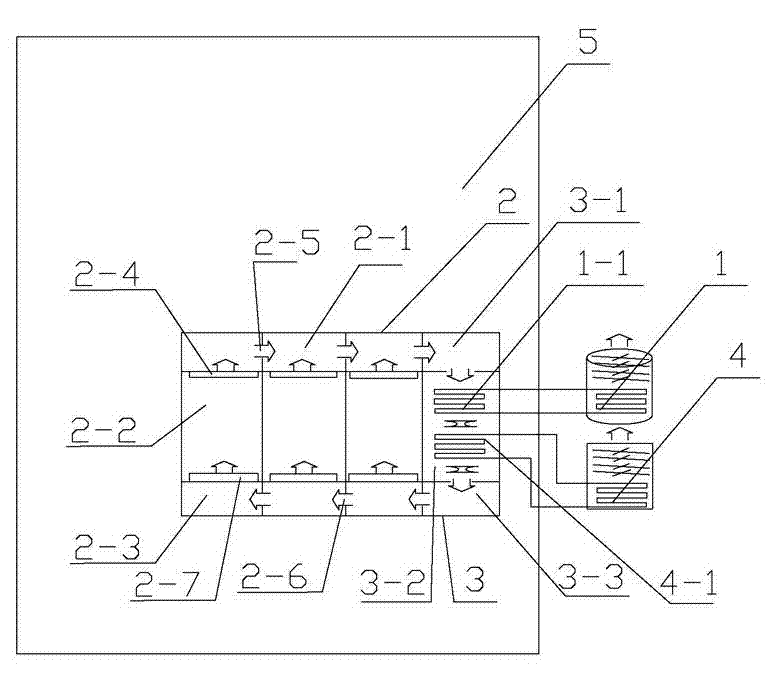

[0022] Example 2: Such as figure 2 As shown, the difference from Embodiment 1 is: the heat exchange device 3-2 is equipped with an air-conditioning evaporator 4-1, and the air-conditioning evaporator 4-1 is installed in the indoor evaporator 1-1 of the heat exchanger. On one side, the air conditioner evaporator 4-1 is connected to the outdoor condenser of the air conditioner 4 outside the machine room 5 through a pipe to form a circulating pipe for auxiliary heat dissipation. In the case of low heat exchange efficiency, the air conditioner 4 serves as an auxiliary refrigeration system to perform auxiliary refrigeration processing on the wind entering the lower air cavity 3-3 in the heat exchange device 3-2.

[0023] Principle analysis of equipment energy saving system:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com