Portable electronic equipment

An electronic device and portable technology, applied in the direction of chassis/cabinet/drawer parts, etc., can solve the problems of uneven lens assembly gap, lens warping, wide frame area, etc., to enhance the sense of product value and solve the gap. The effect of uneven, enlarged display area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

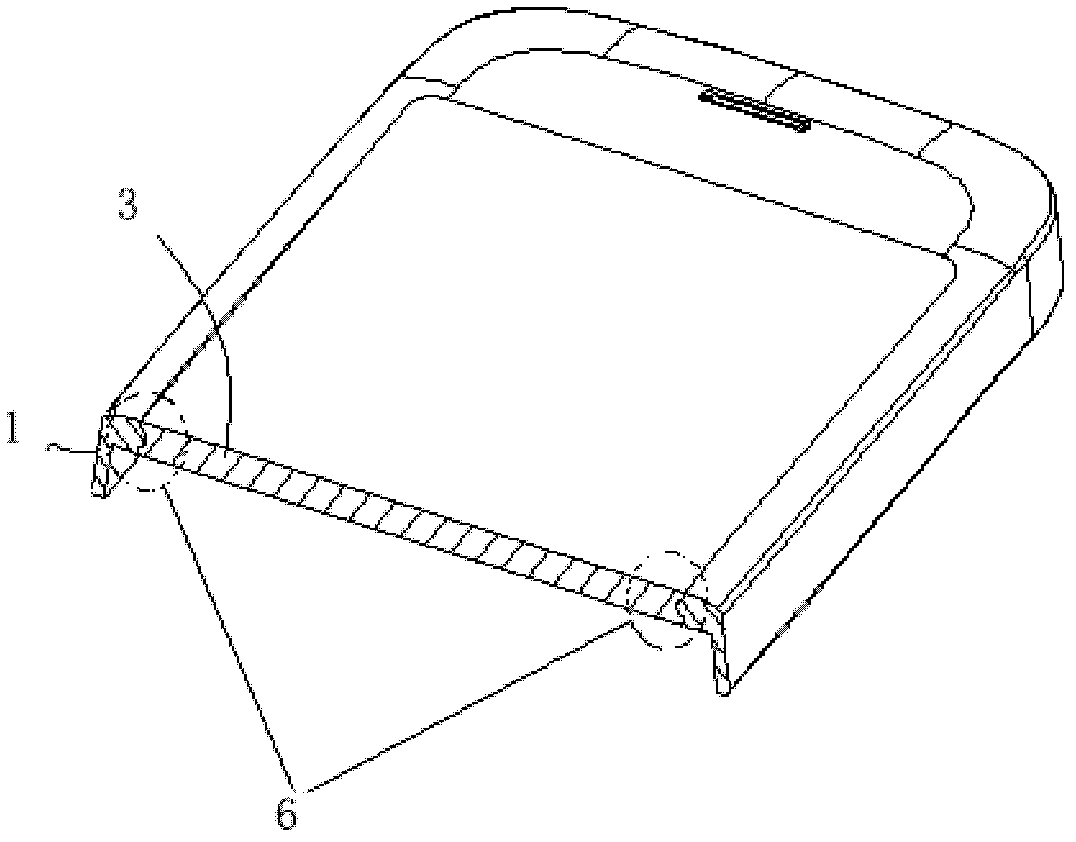

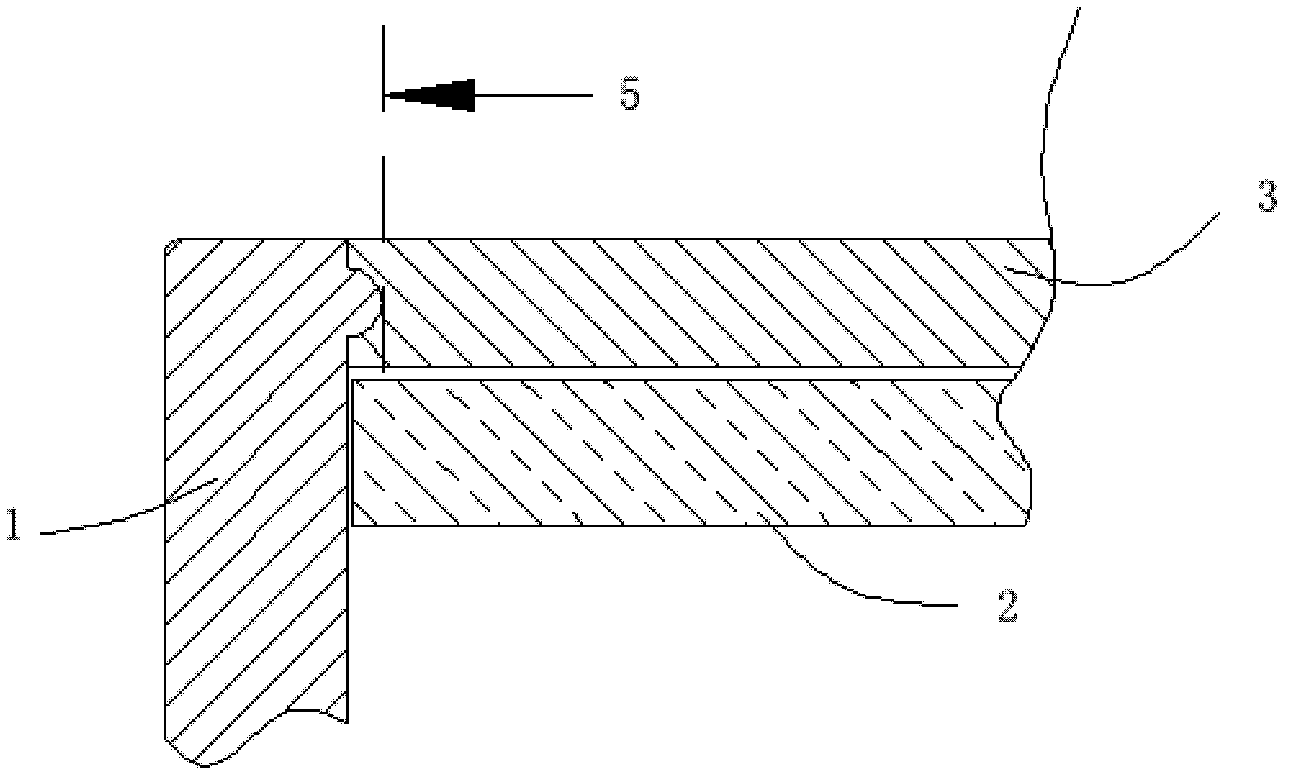

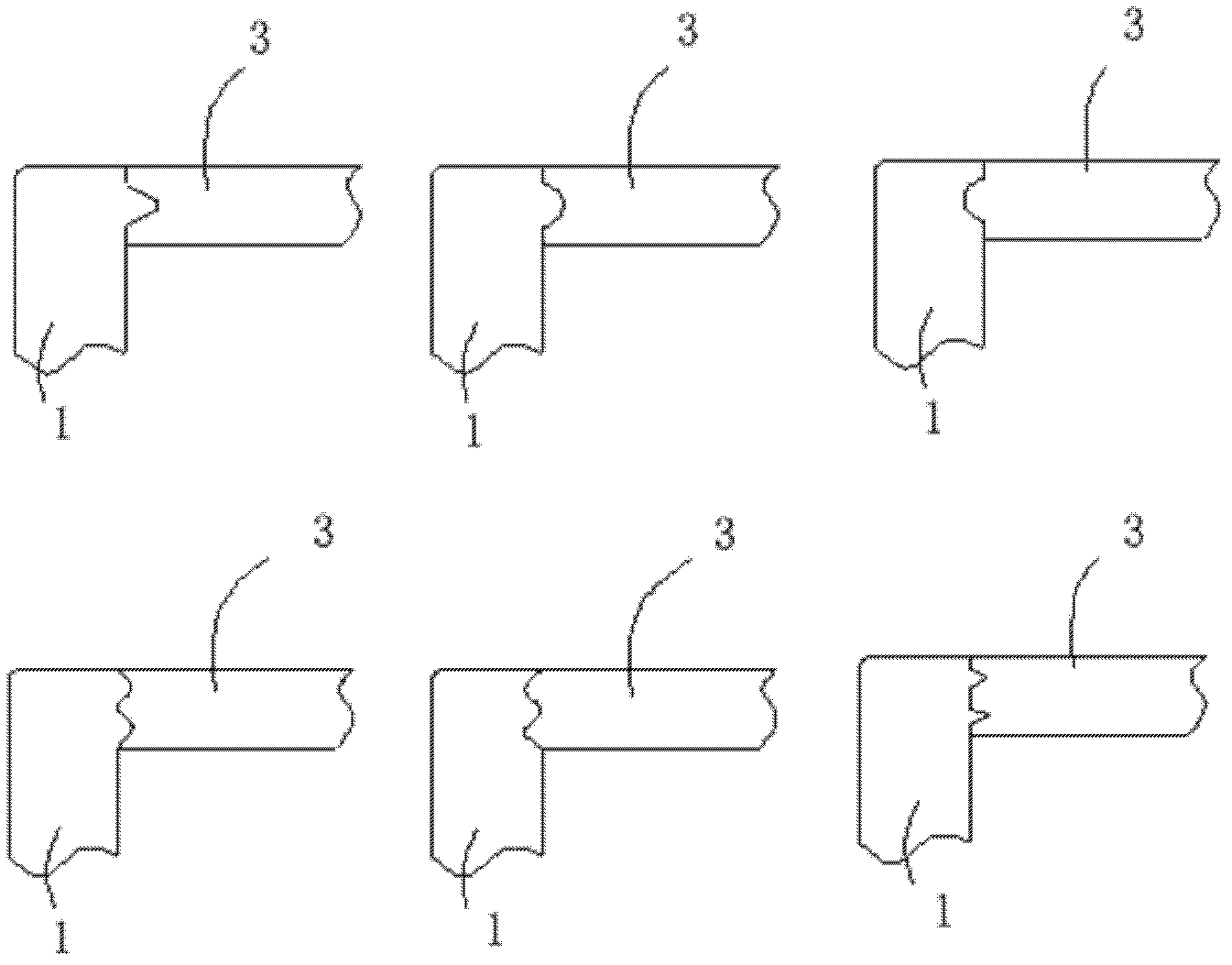

[0040] figure 1 For a mobile phone with a display lens of the present invention, figure 2 It is the structural diagram of the display lens. The display screen 2 is arranged inside the plastic casing 1 , and a glass lens 3 is arranged above the display screen 1 . The bonding surface 6 of the glass lens 3 and the plastic shell 1 is as image 3 shown. The plastic shell 1 is obtained by placing the glass lens 3 in a mold and injection molding. The specific steps are as follows: put the glass lens 3 into the mold, and then cast plastic raw materials. The plastic raw materials fill the periphery of the protective lens and fill the cavity of the mold The other parts of the body are solidified to form the plastic shell 1 and are closely combined with the glass lens 3 at the same time. The display lens does not use double-sided tape, so the displayable area 5 is relatively large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com