Switched reluctance motor driving control system, angle control device and method

A switched reluctance motor, angle control technology, applied in control systems, AC motor control, single motor speed/torque control, etc., can solve the problems that the overall efficiency cannot be optimized, the temperature of switching semiconductor components rises, etc., to achieve efficiency optimization , the effect of reducing the opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

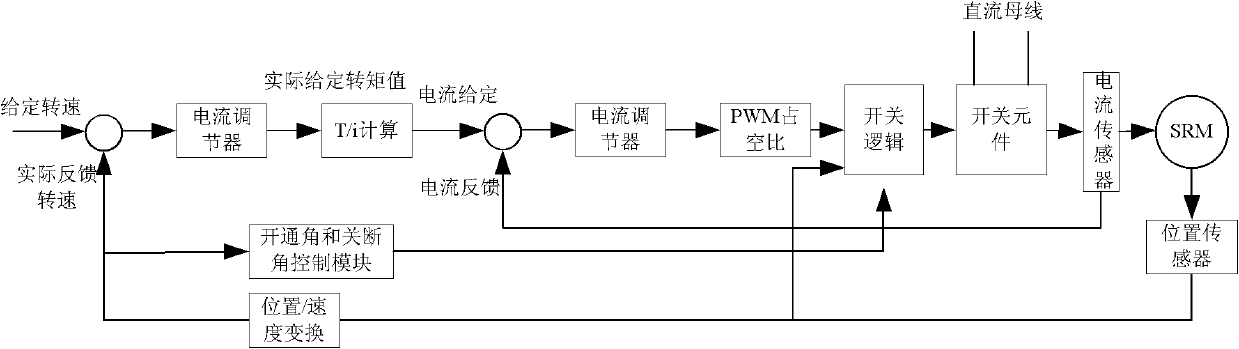

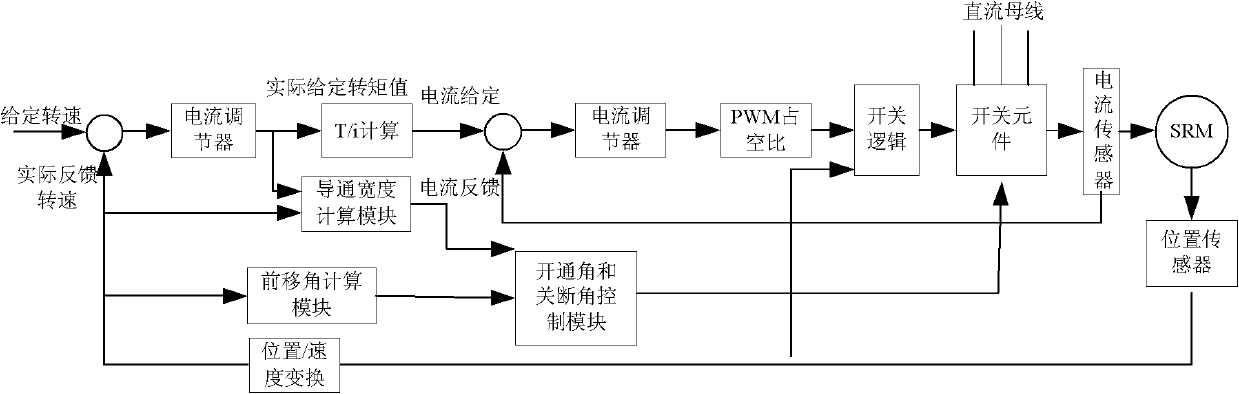

[0037] figure 2 It is a structural diagram of the drive control system of the switched reluctance motor of the present invention. These include: angle control device;

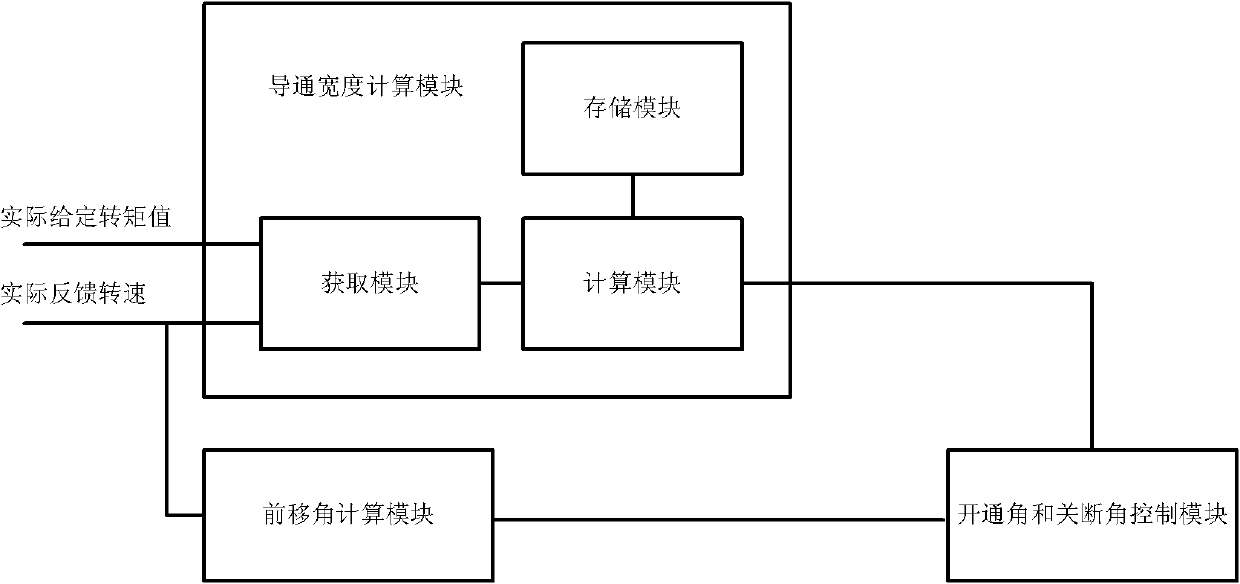

[0038] The angle control device, such as image 3 As shown, it includes: a conduction width calculation module, an advance angle calculation module, and a turn-on angle and turn-off angle control module. The turn-on angle and turn-off angle control modules are used to calculate the conduction width and advance The forward angle calculated by the angle calculation module controls the action of the switching element in the drive control system of the switched reluctance motor to complete the control of the switched reluctance motor. Specifically, according to the conduction width calculated by the conduction width calculation module and the advance angle calculated by the advance angle calculation module, the turn-on angle and turn-off angle control module can obtain the phase conduction interval through progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com