Method for evaluating reliability of aircraft engine aiming at competing failure

An aero-engine, competitive failure technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as increasing analysis complexity, reliability evaluation complexity, and increasing calculation difficulty, and achieves improved data utilization. Efficiency, the effect of improving the efficiency of information utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

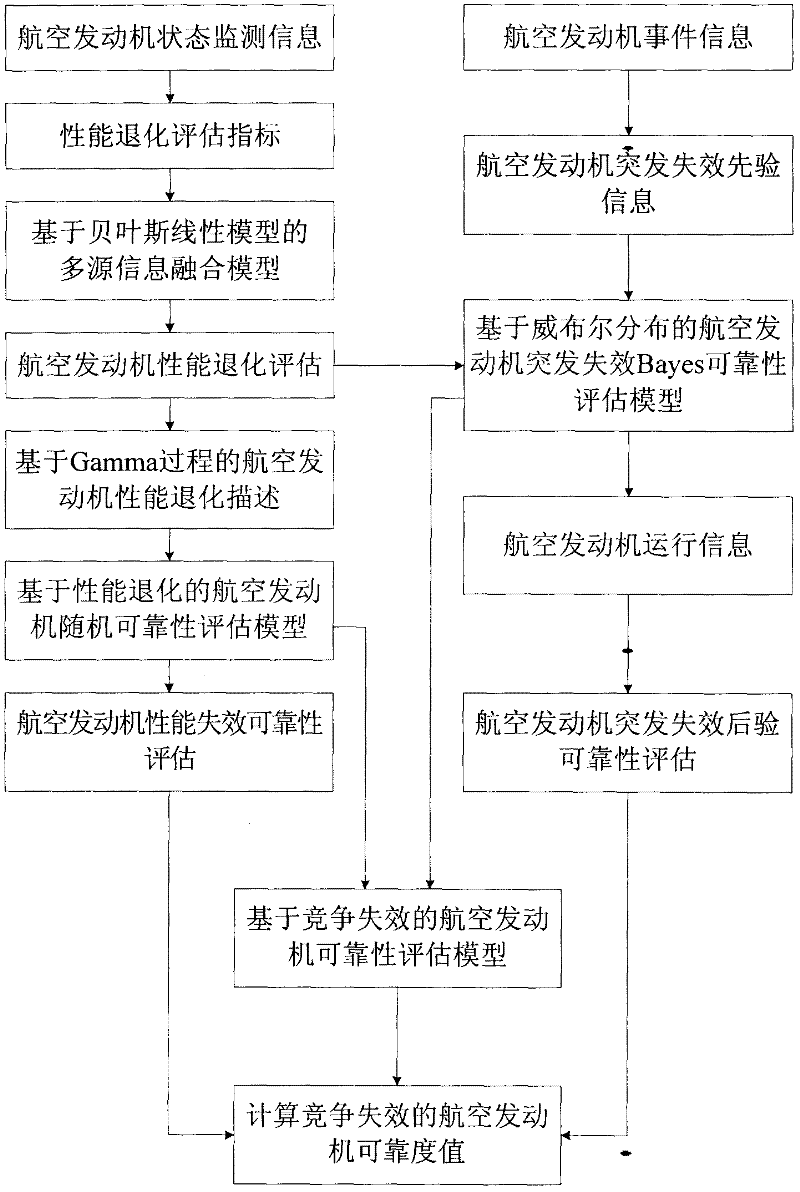

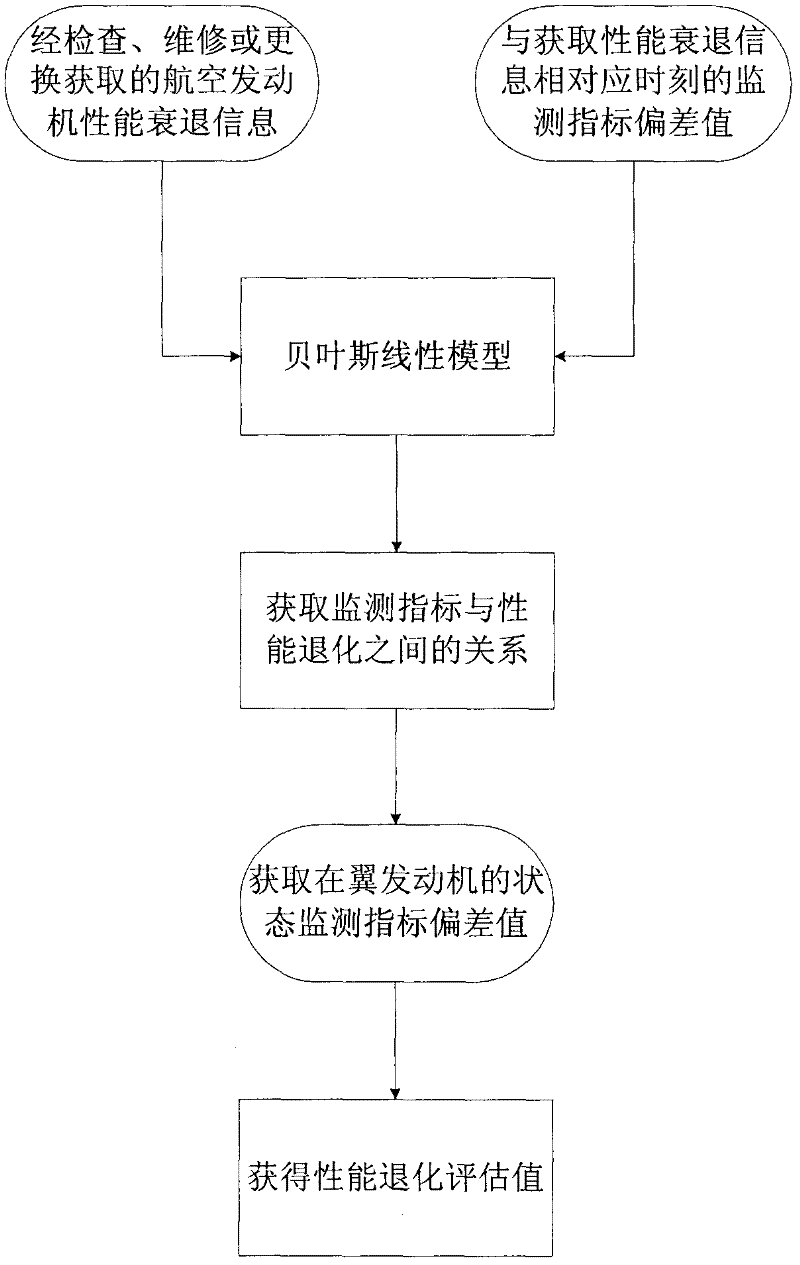

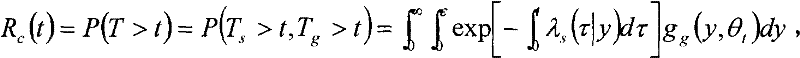

[0019] Aiming at the simultaneous existence of aero-engine sudden failure failure and degradation failure, the two failures are a form of competing failure, which jointly affect the reliability level of aero-engines, an aero-engine reliability evaluation method for competing failures is proposed, and its implementation process can be Divided into the following 6 steps, such as figure 1 shown.

[0020] 1. Analyze the failure rules of aero-engines, analyze the influence of degradation failure and sudden failure failure as two typical failure modes on the reliability level of aero-engines, and judge whether the failure forms of aero-engines belong to competing failures.

[0021] The failure of complex systems is characterized by the coexistence of multiple failure modes. According to different failure mechanisms, it can be divided into performance degradation failure and sudden failure. Sudden failure refers to the sudden loss of specified functions at a certain moment, and degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com