Belt weigher

A belt scale and conveyor belt technology, applied in measuring devices, instruments, weighing and other directions, can solve the problems of not knowing the change of tare weight, measurement error, and difficulty in ensuring the stability of the measurement accuracy of belt scales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

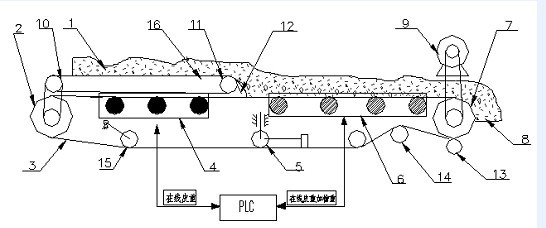

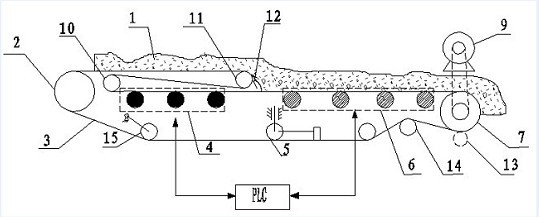

Embodiment 1

[0018] Embodiment one, as attached figure 2 As shown, the present invention provides an electronic belt scale with an online tare function, comprising a belt scale feed area 1, a driven drum 2, a driving drum 7, a tare detection scale platform 4, a material weighing scale platform 6 and a discharge In zone 8, the tare detection weighing platform 4 and the material weighing weighing platform 6 are in the same plane, and the driving roller 7 is driven by the drive motor 9 through the sprocket pair to drive the conveyor belt 3 to move. An isolation belt conveyor 16 is set below the feed area 1, and the isolation belt conveyor 16 includes a forward roller 10 and a turning roller 11, and the forward roller 10 and the turning roller 11 are connected through a belt, and the forward roller 10 and the turning roller 11 are connected by a belt. The driven roller 2 is connected to the roller 10 .

[0019] Open up the installation space for the online tare weighing platform, see attache...

Embodiment 2

[0020] Embodiment two, as attached image 3 , in the feed area 1, there are forward rollers 10 and folding rollers 11 (with antistatic and anti-adhesive coatings), and the belt runs along the image 3 The direction shown in , is wound back along the "S" shape of the folding roller, so as to open up the installation space of the online tare weighing platform under the unloading area, realize the online detection function of tare weight, and maintain the traditional belt scale. The way of feeding and discharging remains unchanged.

[0021] as attached figure 1 As shown, the driving motor 9 drives the driving drum to rotate through the sprocket pair, thereby driving the belt to move. The front-end equipment feeds from the feeding area at the tail of the scale. The material reaches the top of the weighing platform after being folded towards the roller. The weighing platform detects the gross weight of the material, and the gross weight minus the weight below the feeding area Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com