Light emitting diode (LED) full light angle bulb

A full light angle and light bulb technology, which is applied to light sources, lampshades, electric light sources, etc., can solve the problems of LED heat concentration, high phosphor cost, and insufficient power supply design space for light bulbs, so as to prolong life and increase design space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

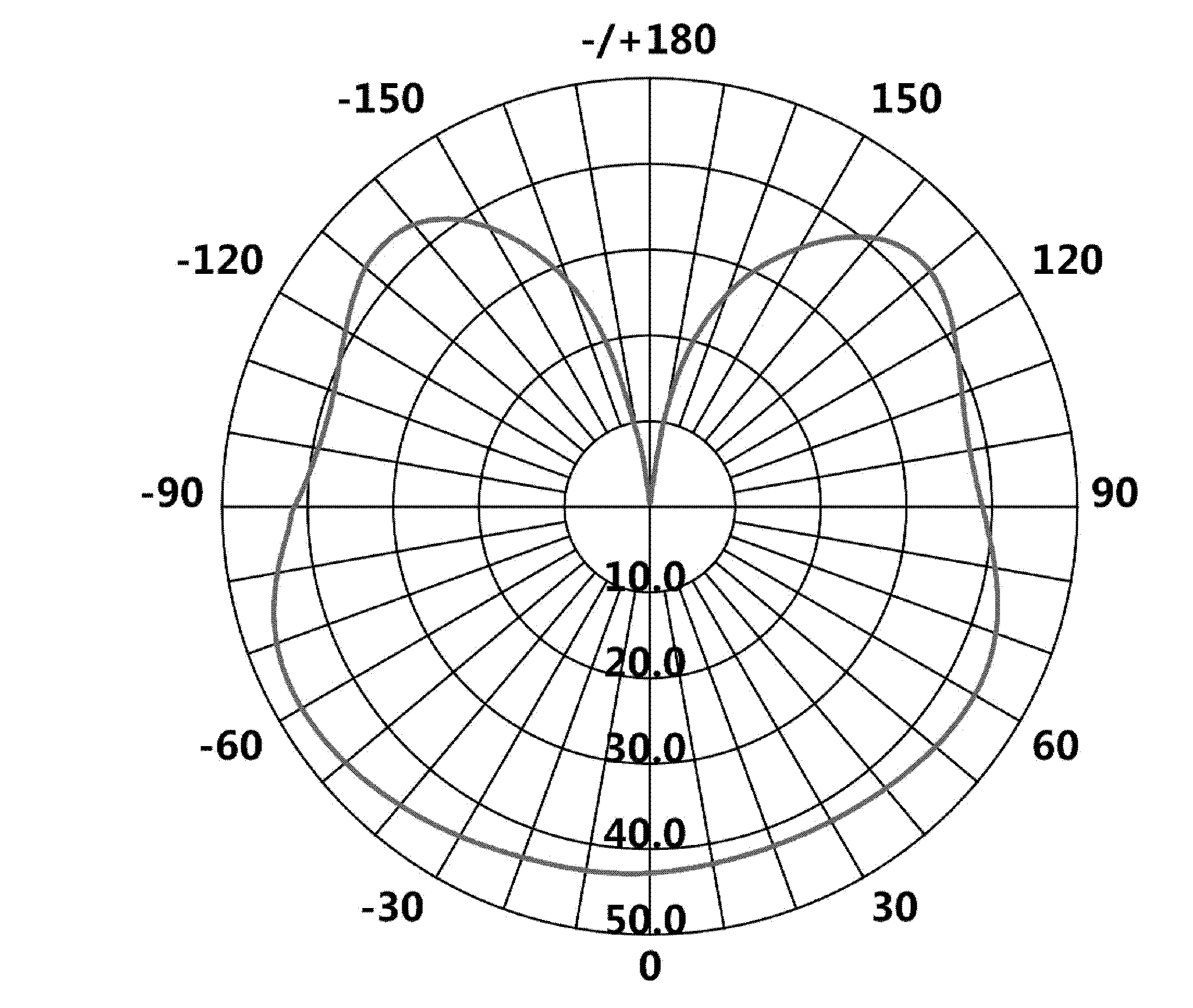

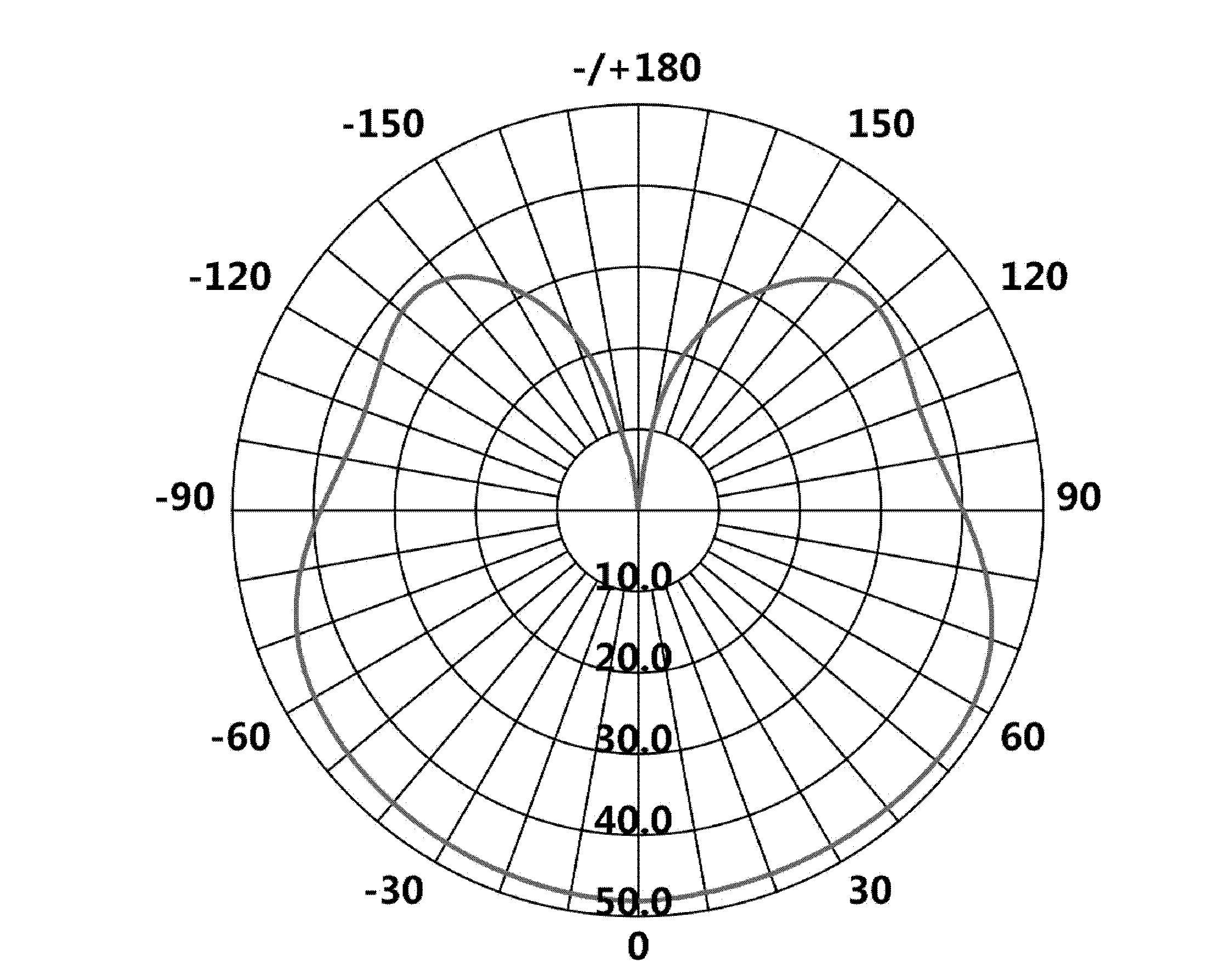

[0024] An embodiment of the present invention provides an LED full-light angle bulb, referring to figure 1 , the LED full-light angle bulb includes a lamp housing 1 , a light source 2 and a reflection unit 3 , and the light source 2 and the reflection unit 3 are arranged inside the lamp housing 1 .

[0025] The lamp housing 1 includes a bulb 11 and a radiator 12 , the bulb 11 and the radiator 12 are connected to form a closed chamber, and the light source 2 and the reflection unit 3 are arranged in the closed chamber. The bulb 11 includes an inner bulb 111 and an outer bulb 112. The advantage of setting two layers of bulbs 11 is that after the light passes through the inner bulb 111, it is refracted by the outer bulb 112 to realize secondary light distribution. .

[0026] In a specific embodiment, the inner bulb 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com