Transmission gear of tube mill

A transmission device and tube mill technology, applied in the direction of transmission device, transmission device parts, gear transmission device, etc., can solve the problems of large maintenance workload, high operation failure rate, large size of reducer, etc., and achieve short installation period, The effect of less capital investment and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

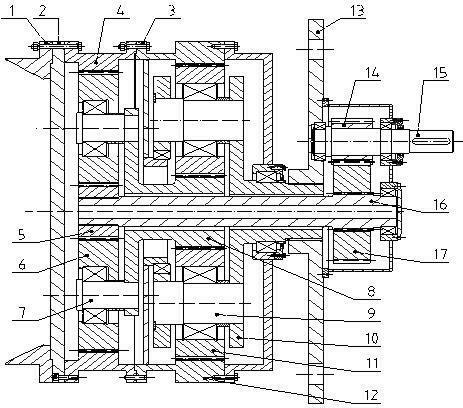

[0020] Such as figure 1 As shown, the transmission device is a first-stage parallel gear reduction + a second-stage planetary gear reduction; the input shaft 15 is installed on the torque frame 13, and the input gear 14 on the input shaft 15 meshes with the input mating gear 17, and the input gear 14 and the input mating gear 17 The first-stage parallel gear reduction is completed; the flexible hollow shaft 16 is installed in the center of the connecting box 3, the input mating gear 17 and the flexible hollow shaft 16 are connected by splines, and the flexible hollow shaft 16 is rigid to the second-stage sun gear 5 Combined together, the second-stage planetary gear 6 on the second-stage planetary shaft 7 meshes with the second-stage sun gear 5, and the second-stage internal ring gear 4 is installed between the coupling box 3 and the flange 2 of the reducer box. The second-stage planetary gear 6 drives the second-stage ring gear 4 to complete the second-stage planetary gear red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com