Shaft and rod micro-clearance direct-connection technology

A shaft and direct connection technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve problems such as increments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

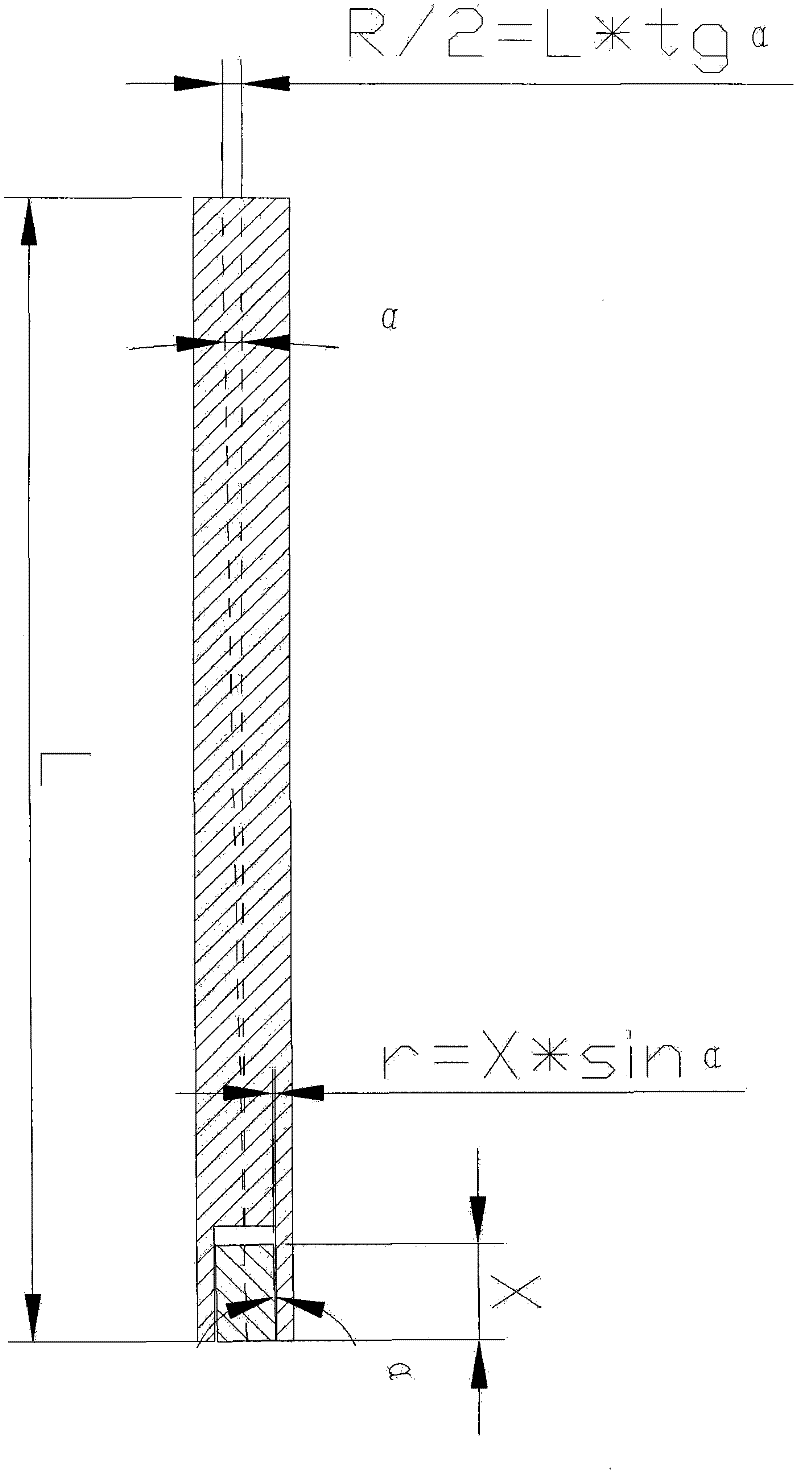

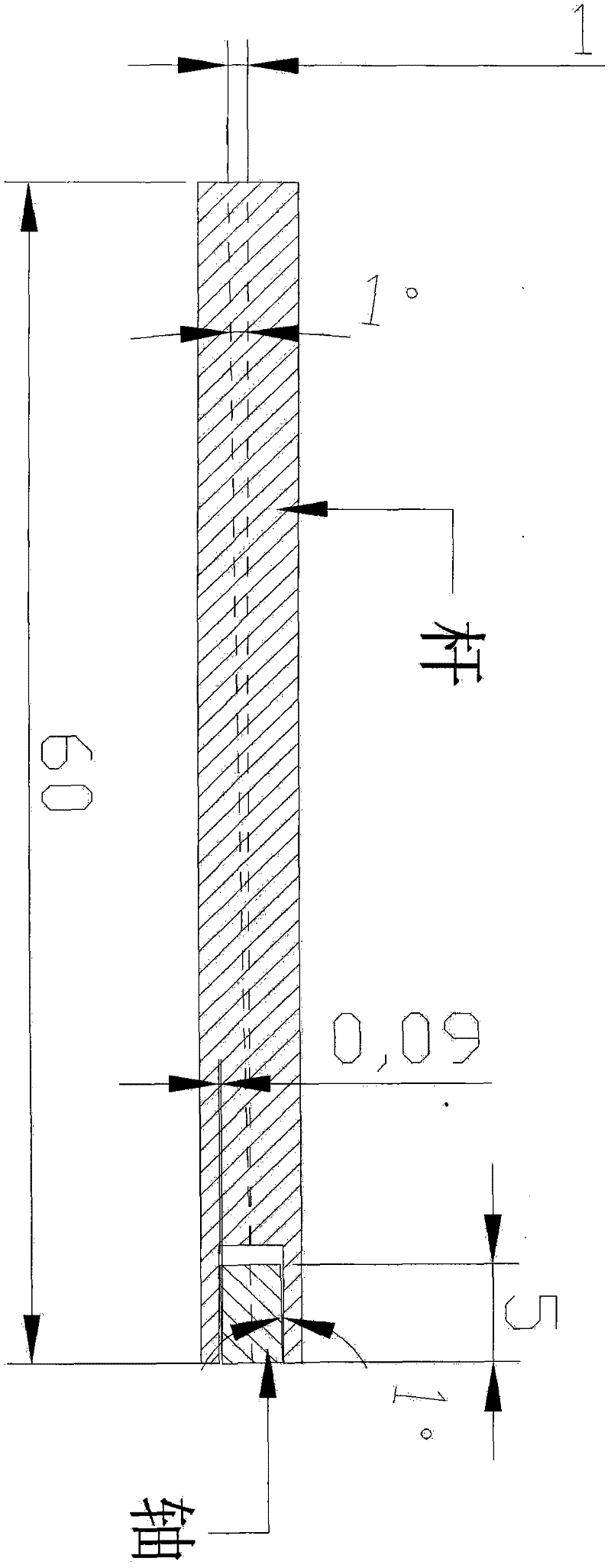

Method used

Image

Examples

Embodiment Construction

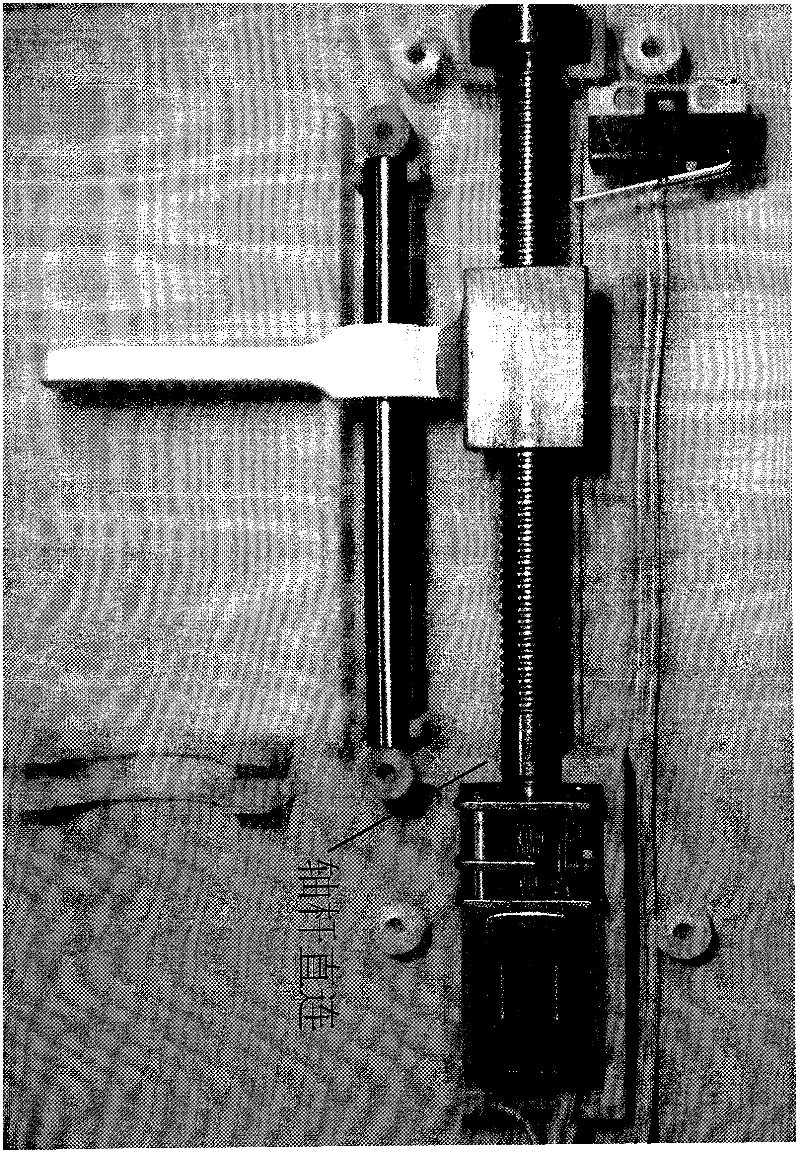

[0008] A typical application is the mechanical transmission part of the "automatic fascial pressure measuring instrument" (attached image 3 ), the automatic fascia pressure measuring instrument is a special device for measuring the pressure of the fascia chamber, which is mainly used in orthopedics. Due to the small space and battery power supply, it uses a miniature geared motor with a 3mm D-type shaft and a 5mm screw for direct connection. This technology eliminates the transmission intermediate structure, and the reserved gap is 0.12mm calculated by the above method. Practice has proved that it is reliable in operation, can effectively eliminate adverse stress and shaking, and the space occupation reaches the minimum limit and the loss is low. This instrument has no requirements for hysteresis, and the actual use effect is very ideal.

[0009] This is a power transmission method that not only saves space, but also reduces costs. It really solves the problem that the error ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com