Diaphragm compressed valve-less micropump

A compression-type, micro-pump technology, applied in the direction of pumps, pump components, variable-capacity pump components, etc., can solve the problems of high driving voltage and complex processing technology, and achieve the effects of prolonging service life, easy processing, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

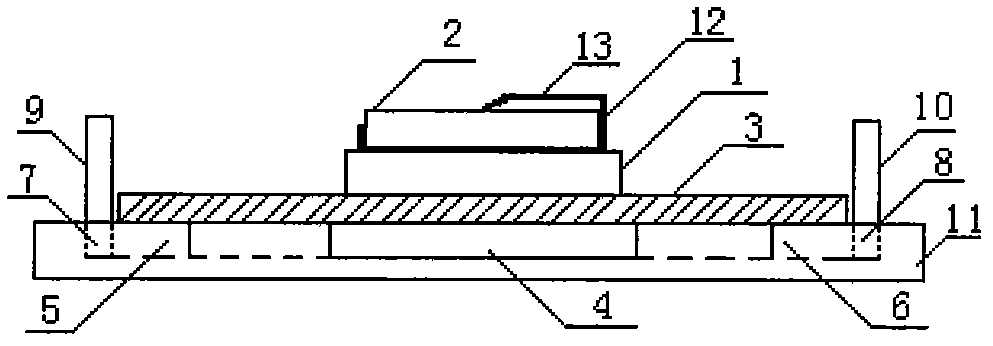

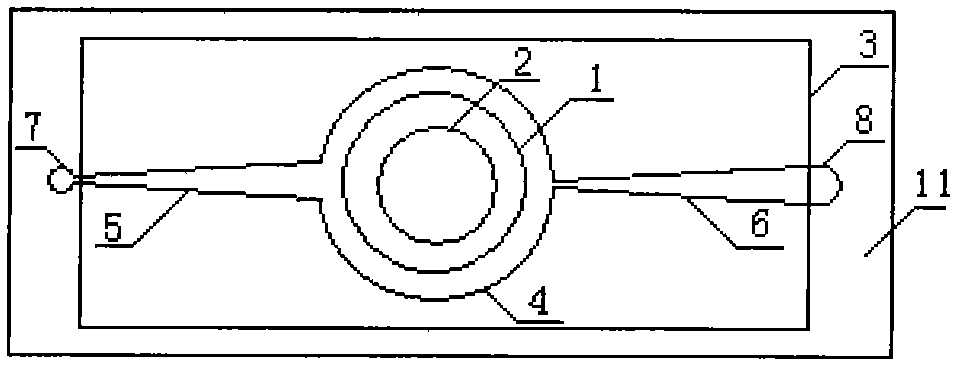

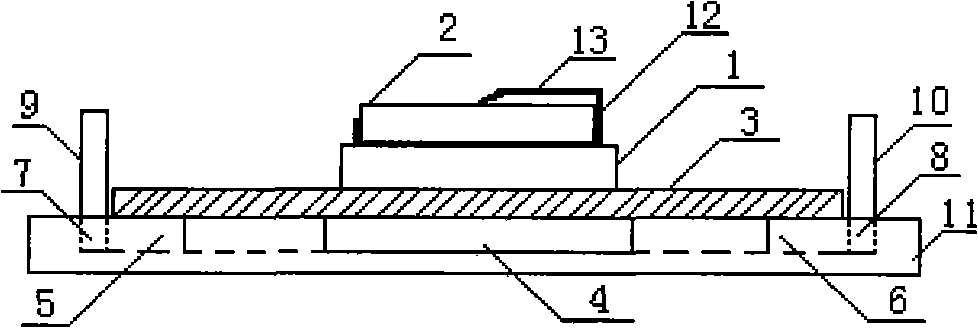

[0011] Such as figure 1 , figure 2 As shown, there is a pump chamber 4, a conical diffusion channel 5, a conical contraction channel 6, a left water hole 7 and a right water hole 8 on the pump body 11, and there is a layer of silicone rubber pump membrane on the upper surface of the pump body 11. 3. The top of the silicone rubber pump membrane 3 is bonded with the micro-vibration motor 1 with resin glue, and the button battery holder 12 is installed on the micro-vibration motor 1. The button battery is installed in the button battery holder. There is a spring piece 13 on the button battery holder. There is a plastic sheet between the sheet 13 and the button battery 2, the plastic sheet can be taken out when the micropump works, and the plastic sheet can be inserted when the micropump stops working. The pump chamber 4 is connected with the left water hole 7 through the tapered diffusion channel 5, and connected with the right water hole 8 through the tapered shrinkage channel...

Embodiment approach 2

[0016] The narrow mouth width of the tapered diffusion channel 5 and the tapered constriction channel 6 of the micropump is 100 μm, the width of the wide mouth is 500 μm, the length is 2.3 mm, and the angle is 10°; the diameter of the pump chamber of the micropump is 8 mm, and the depth is 0.5 mm The thickness of the pump membrane of the micropump is 0.25mm, and the above dimensions are the best values obtained after simulation. The pump body 11 is made of glass material, and the others are the same as in Embodiment 1.

Embodiment approach 3

[0018] The narrow mouth width of the tapered diffusion channel 5 and the tapered constriction channel 6 of the micropump is 100 μm, the width of the wide mouth is 500 μm, the length is 2.3 mm, and the angle is 10°; the diameter of the pump chamber of the micropump is 8 mm, and the depth is 0.5 mm The thickness of the pump membrane of the micropump is 0.25mm, and the above dimensions are the best values obtained after simulation. The pump body 11 is made of silicon material, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com