Exchange transmission device of three-dimensional garage

A technology of three-dimensional garage and transmission device, which is applied in the field of garages storing multiple vehicles, and can solve problems such as complex structure, long time-consuming parking and picking up cars, etc., and achieve the effects of high safety performance, simple and convenient access, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

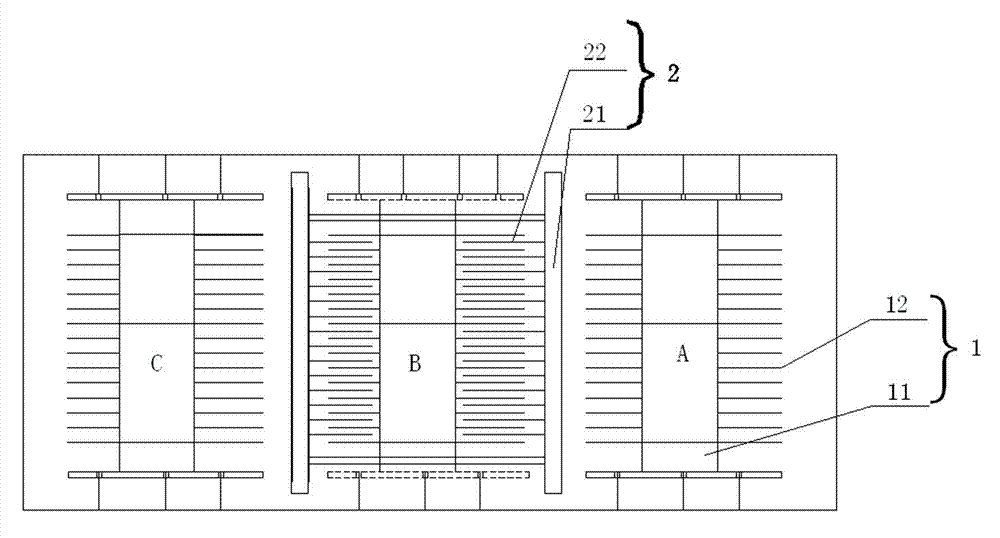

[0022] As shown in the figure, the exchange transmission device of the three-dimensional garage includes a vertical transport elevator 1 , a vehicle platform 2 and a horizontal transmission device 3 .

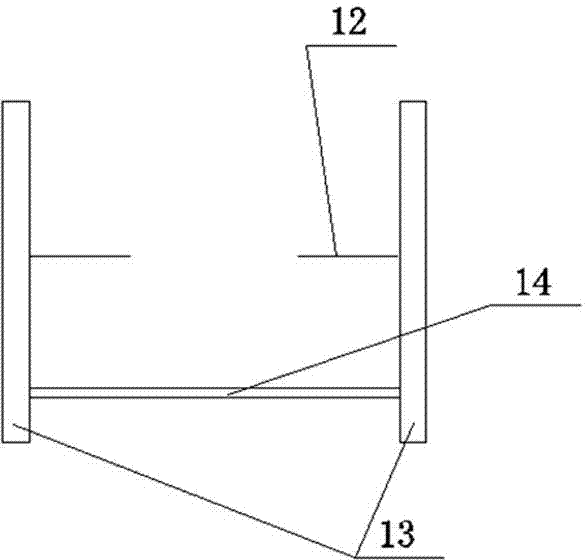

[0023] The vertical transport elevator 1 includes brackets 11 arranged on both sides and bracket teeth 12 fixed to the inner side of the brackets 11 and arranged at intervals. like image 3 and Figure 4 As shown, the aforementioned vertical transport elevator 1 further includes a support plate 14 fitted with support columns 13 at four corners, and both ends of the aforementioned bracket 11 are respectively fixed to the adjacent support columns 13 . The support column 13 and the support plate 14 cooperate with each other to form a support frame of the vertical transportation elevator 1 , and play a role of supporting the entire vertical transportation elevator 1 . The support plate 14 may be located below or above the bracket teeth 12 , and both can play a supporting role of ...

Embodiment 2

[0031] like figure 2 As shown, the comb structure of the second embodiment adopts a half-tooth structure, and the ends of the two sides of the bracket 11 are fitted with the bracket teeth 12, and the middle part is not installed with the bracket teeth 12. Bracket teeth 22 are fitted at both ends of the bracket 21 , and bracket teeth 22 are not installed in the middle.

[0032] In the second embodiment, when the effect of the comb structure is exerted, the material is saved, the weight of the vehicle exchange device is reduced, the cost is saved, and the effect is improved.

[0033] The other structures of the second embodiment are the same as those of the first embodiment, and are not repeated here.

[0034] In conjunction with the accompanying drawings, the working process of the present invention is as follows (vehicle storage to position A):

[0035] Vehicle parking: When in use, the vehicle drives into the vertical transportation elevator 1 of the three-dimensional gara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com