Preparation method of electrostatic spinning fibers with axial-orientation structures on cylindrically tubular support and device for realizing same

An axially oriented, cylindrical technology, used in textile and papermaking, medical science, fiber processing, etc., to solve problems such as inability to rotate the device, limiting the length of tubular stents, and uneven fiber deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

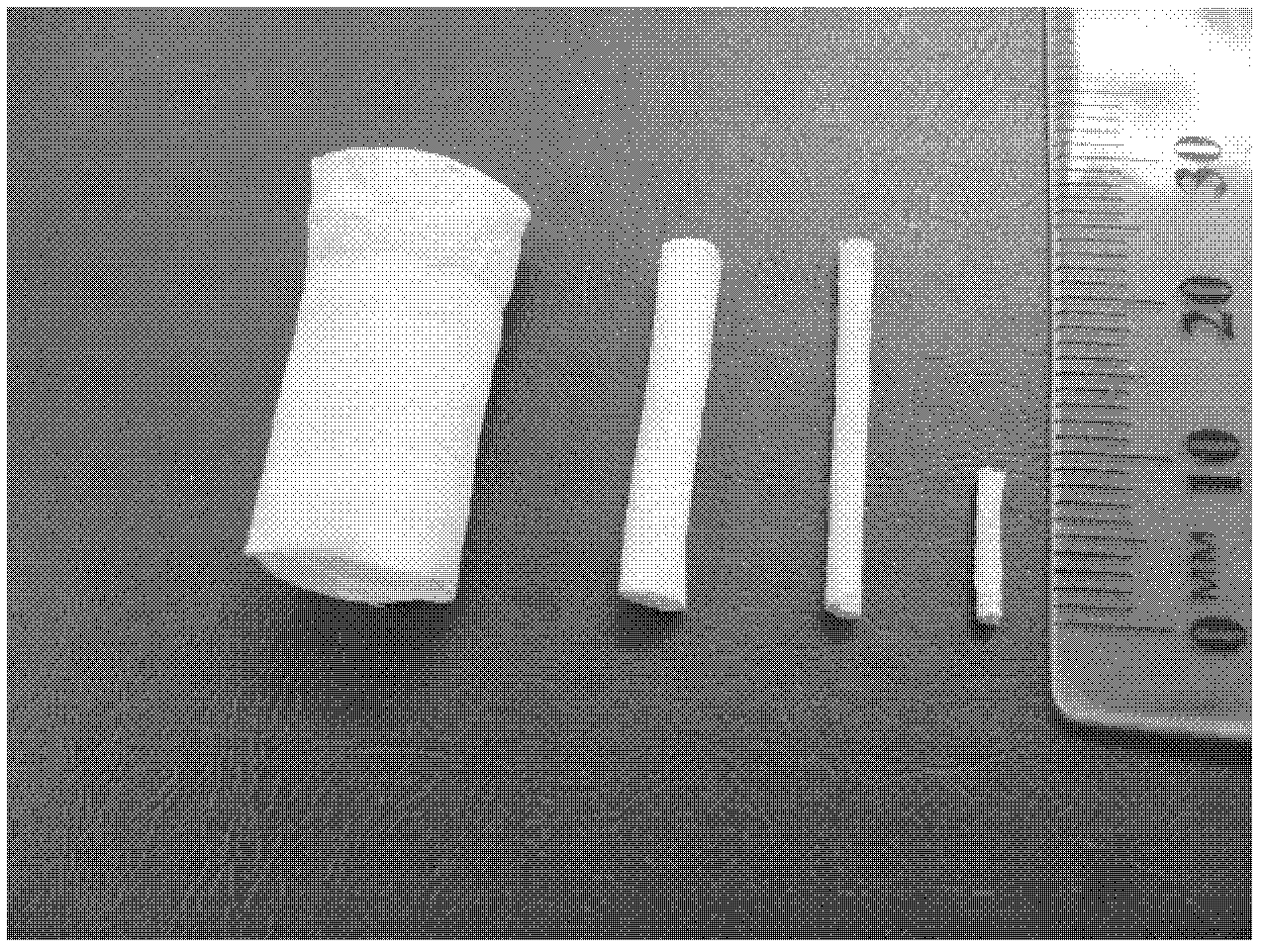

Embodiment 1

[0029] According to the aforementioned method for preparing a cylindrical tubular stent with an axially oriented structure in the present invention, including the preparation of spinning solution, the collection of electrospun fibers and the steps of taking out and storing the tubular stent, the following process conditions are adopted:

[0030] (1) Dissolve 0.8 g of collagen in 10 ml of hexafluoroisopropanol, stir magnetically for 12-24 hours until completely dissolved, and obtain a collagen solution with a concentration of 8% (g / ml).

[0031] (2) Electrospinning is carried out through a rotating receiving device, spinning conditions: voltage 15 kV; receiving distance 150 mm; spinning rate, 1.0 ml / hour, rotation rate 10 rpm, diameter of the insulating section of the rotating shaft 2 mm, length 20 mm.

[0032] (3) After 2 hours of continuous electrospinning, the rotating shaft was removed, and the fiber membrane deposited on it was drawn out to obtain a tubular scaffold of col...

Embodiment 2

[0035] According to the aforementioned method for preparing a cylindrical tubular stent with an axially oriented structure in the present invention, including the preparation of spinning solution, the collection of electrospun fibers and the steps of taking out and storing the tubular stent, the following process conditions are adopted:

[0036] (1) Dissolve 0.75 g of polylactic acid in 10 ml of hexafluoroisopropanol, stir magnetically for 12-24 hours until completely dissolved, and obtain a polylactic acid solution with a concentration of 7.5% (g / ml).

[0037] (2) Electrospinning is carried out through a rotating receiving device, spinning conditions: voltage, 12 kV; receiving distance, 150 mm; spinning rate, 1.0 ml / hour, rotation rate 50 rpm, diameter of the insulating section of the rotating shaft 3 mm , length 20 mm.

[0038] (3) After 5 hours of continuous electrospinning, the rotating shaft was removed, and the fiber film deposited on it was drawn out to obtain a polylac...

Embodiment 3

[0041] According to the aforementioned method for preparing a cylindrical tubular stent with an axially oriented structure in the present invention, including the preparation of spinning solution, the collection of electrospun fibers and the steps of taking out and storing the tubular stent, the following process conditions are adopted:

[0042] (1) Dissolve 1.0 g of polycaprolactone in 10 ml of dichloromethane, and magnetically stir for 12-24 hours until completely dissolved to obtain a polycaprolactone solution with a concentration of 10% (g / ml).

[0043] (2) Electrospinning is carried out through a rotating receiving device, spinning conditions: voltage, 20 kV; receiving distance, 20 mm; spinning rate, 1.5 ml / hour, rotation rate 50 rpm, diameter of the insulating section of the rotating shaft 10 mm , length 50 mm.

[0044] (3) After continuous electrospinning for 6 hours, the rotating shaft was removed, and the fiber film deposited on it was drawn out to obtain a tubular sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com