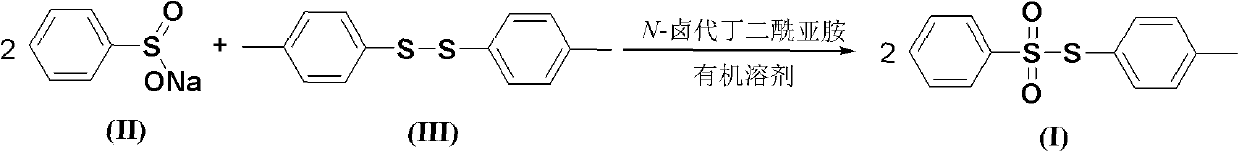

Chemical synthesis method for S-(4-tolyl)benzene sulfonate

A technology for the chemical synthesis of benzenesulfonate, which is applied in the field of chemical synthesis of S-benzenesulfonate, can solve the problems of high risk factor, high volatility, and high requirements, and achieve environmental friendliness, less three wastes, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ratio of bis(4-tolyl) disulfide, sodium benzene sulfinate, and N-halogenated succinimide is 1:4.0:2.0 according to the amount of feed material, and bis(4-tolyl) disulfide 24.6g (0.1mol); sodium benzene sulfinate 64.8g (0.4mol); N-halogenated succinimide is N-bromosuccinimide, feeding quality 35.6g (0.2mol); organic solvent Be acetonitrile 369g, its total consumption is 15 times of two (4-tolyl) disulfide quality.

[0020] Dissolve sodium benzenesulfinate and N-halogenated succinimide in an organic solvent (the amount of organic solvent used is 9 times the mass of bis(4-tolyl) disulfide). Dissolve bis(4-tolyl) disulfide in an organic solvent (the amount of organic solvent is 6 times the mass of bis(4-tolyl) disulfide), slowly add dropwise to sodium benzenesulfinate and N-halogenated In the solution of succinimide, the reaction temperature is 50° C., and the reaction ends after 6 hours.

[0021] After completion of the reaction, add saturated brine, extract and sepa...

Embodiment 2

[0024] The ratio of bis(4-tolyl) disulfide, sodium benzenesulfinate, and N-halogenated succinimide is 1:3.0:2.0 according to the ratio of the feed material, and bis(4-tolyl) disulfide 24.6g (0.1mol); sodium benzene sulfinate 48.6g (0.3mol); N-halogenated succinimide is N-bromosuccinimide, feeding quality 35.6g (0.2mol); organic solvent Be acetonitrile 369g, its total consumption is 15 times of two (4-tolyl) disulfide quality.

[0025] The reaction temperature was 25° C., and the reaction time was 6 hours. Other operations were the same as in Example 1. S-(4-tolyl)benzenesulfonate was 39.1 g, the yield was 74%, and the purity was 98.8%.

Embodiment 3

[0027] The ratio of bis(4-tolyl) disulfide, sodium benzenesulfinate, and N-halogenated succinimide is 1:2.0:2.0 according to the ratio of the feed material, and bis(4-tolyl) disulfide 24.6g (0.1mol); sodium benzene sulfinate 32.4g (0.2mol); N-halogenated succinimide is N-bromosuccinimide, feeding quality 35.6g (0.2mol); organic solvent Be acetonitrile 369g, its total consumption is 15 times of two (4-tolyl) disulfide quality.

[0028] The reaction temperature was 25° C., and the reaction time was 10 hours. Other operations were the same as in Example 1. S-(4-tolyl)benzenesulfonate was 28.2 g, the yield was 53%, and the purity was 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com