Novel hanger for changing radiant tubes

A radiant tube, a new type of technology, applied in the direction of the lifting device, etc., can solve the problems of poor control of the driving force, poor control, excessive radiant tube, etc., to reduce the risk of excessive insertion and the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with implementation examples and accompanying drawings, but the present invention is not limited.

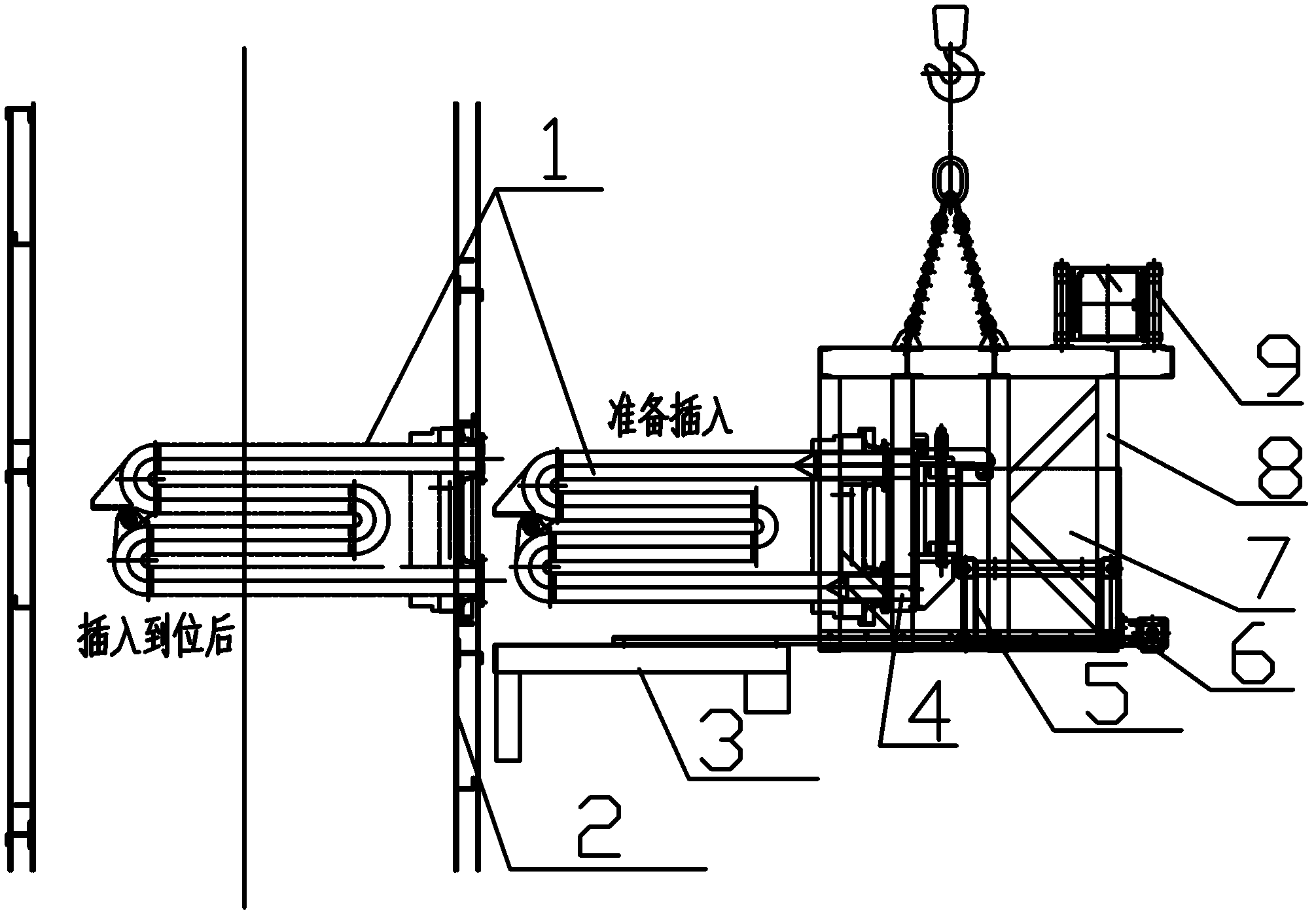

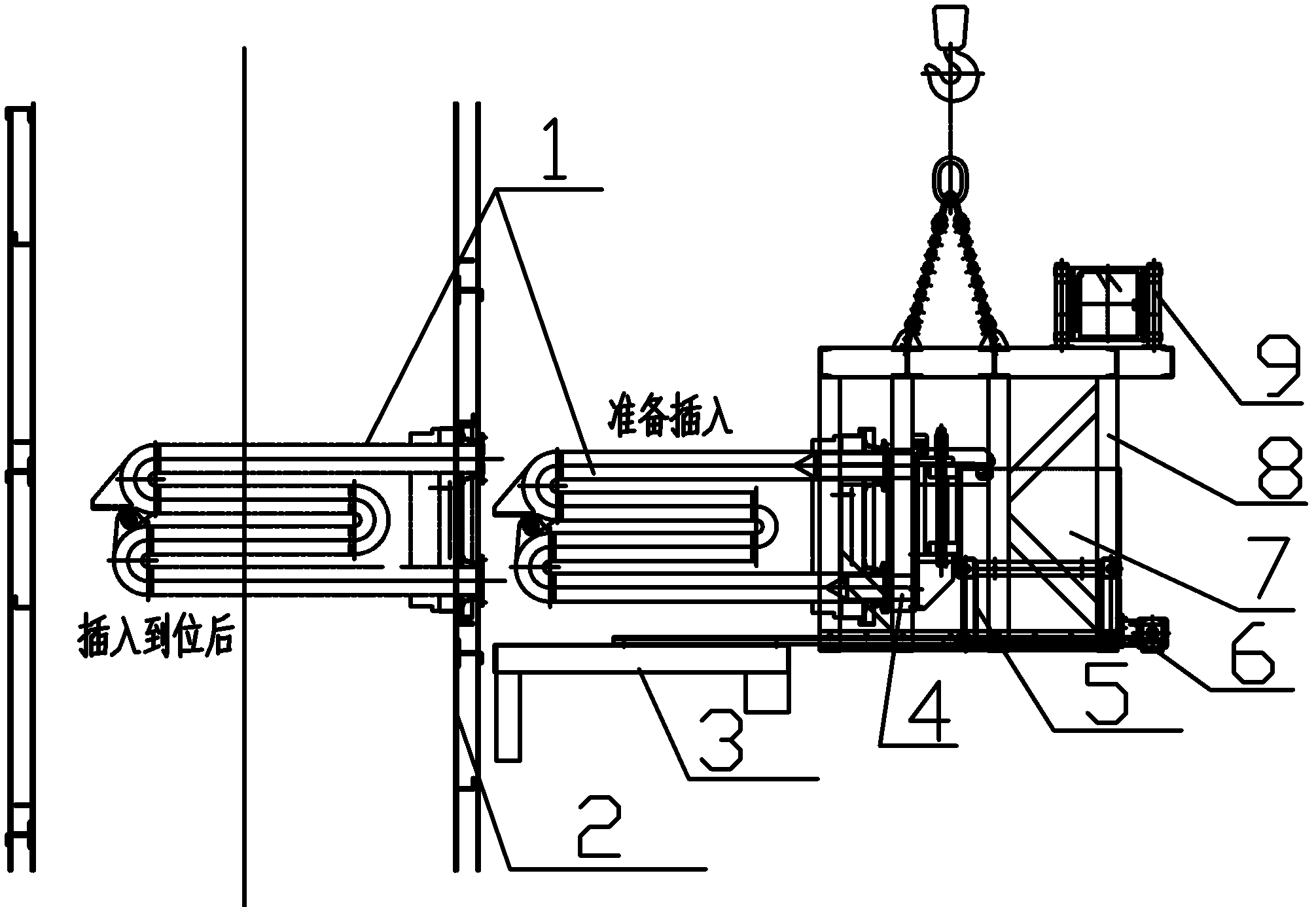

[0015] figure 1 Shown is the novel radiant tube replacement hanger implemented according to the present invention, which is characterized in that it mainly includes a main frame 8 for driving and lifting, and the trolley 5 is arranged on the main frame 8 and can move along the frame 8; the space of the main frame 8 Inner trolley 5 ends are connected with the plunger 4 of fixedly supporting radiant tube, and dolly 5 itself is equipped with configuration box 7, and dolly 5 can drive chain by transmission gear machine 6 on frame 8 to control the advancement and retreat of dolly.

[0016] During operation, the electric control box 9 is controlled by the operation button to realize the advancement of the trolley. After the trolley advances, the radiant tube 1 is fixed, and the trolley 5 is returned to the rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com