Novel traction machine brake device

A technology for braking and braking devices of traction machines, which is applied to hoisting devices, transportation and packaging, elevators in buildings, etc. The effect of structure, weight reduction, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

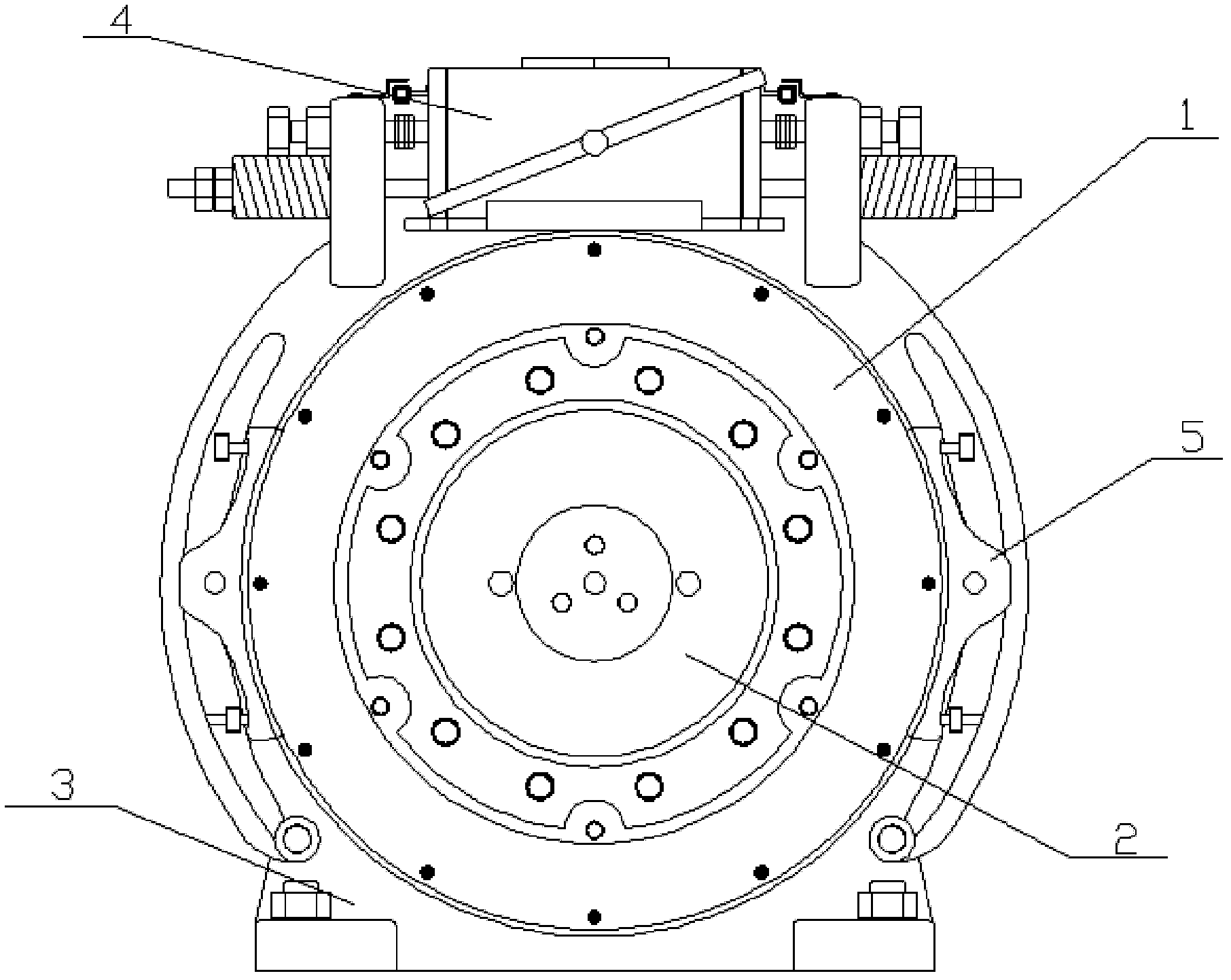

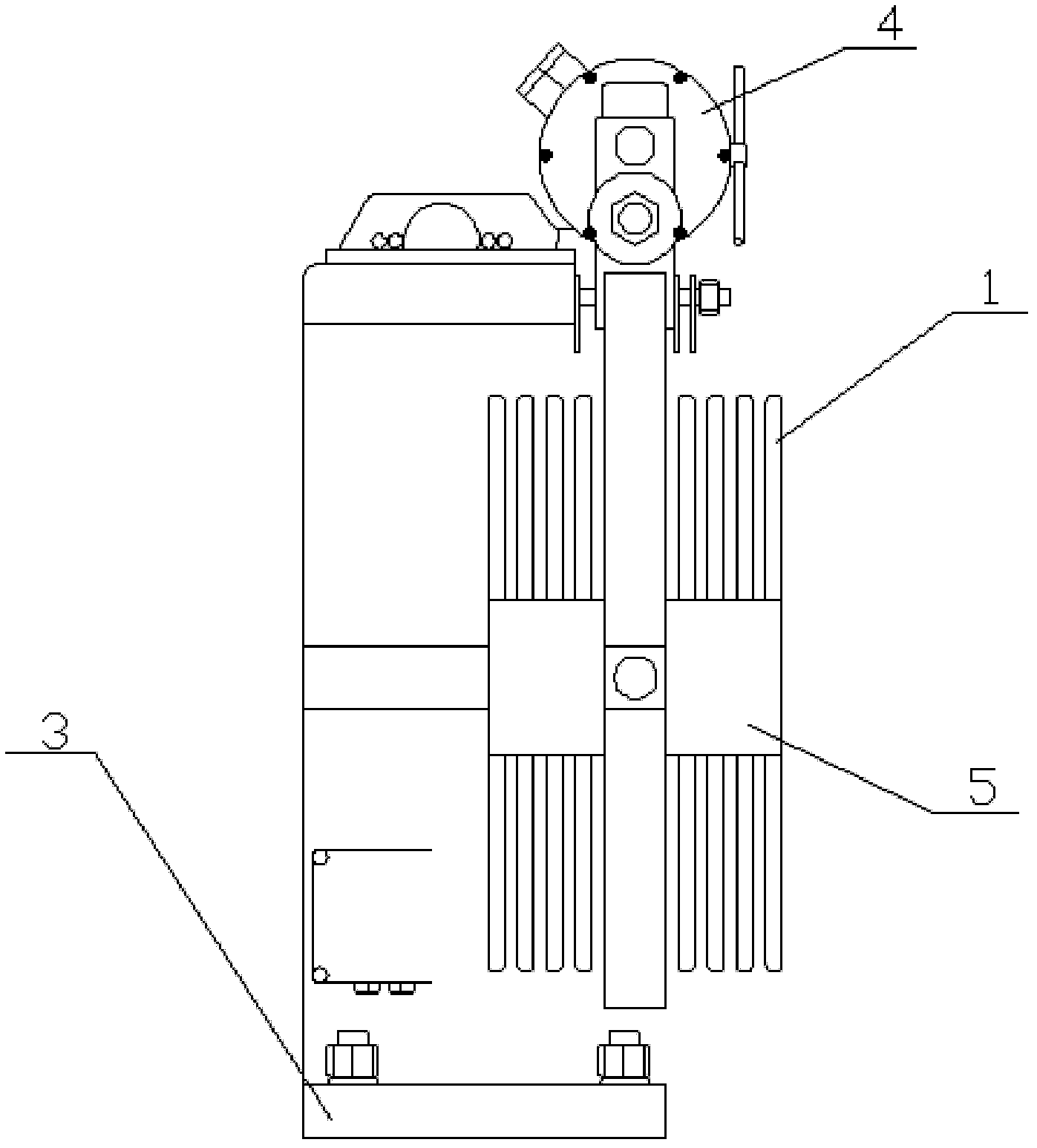

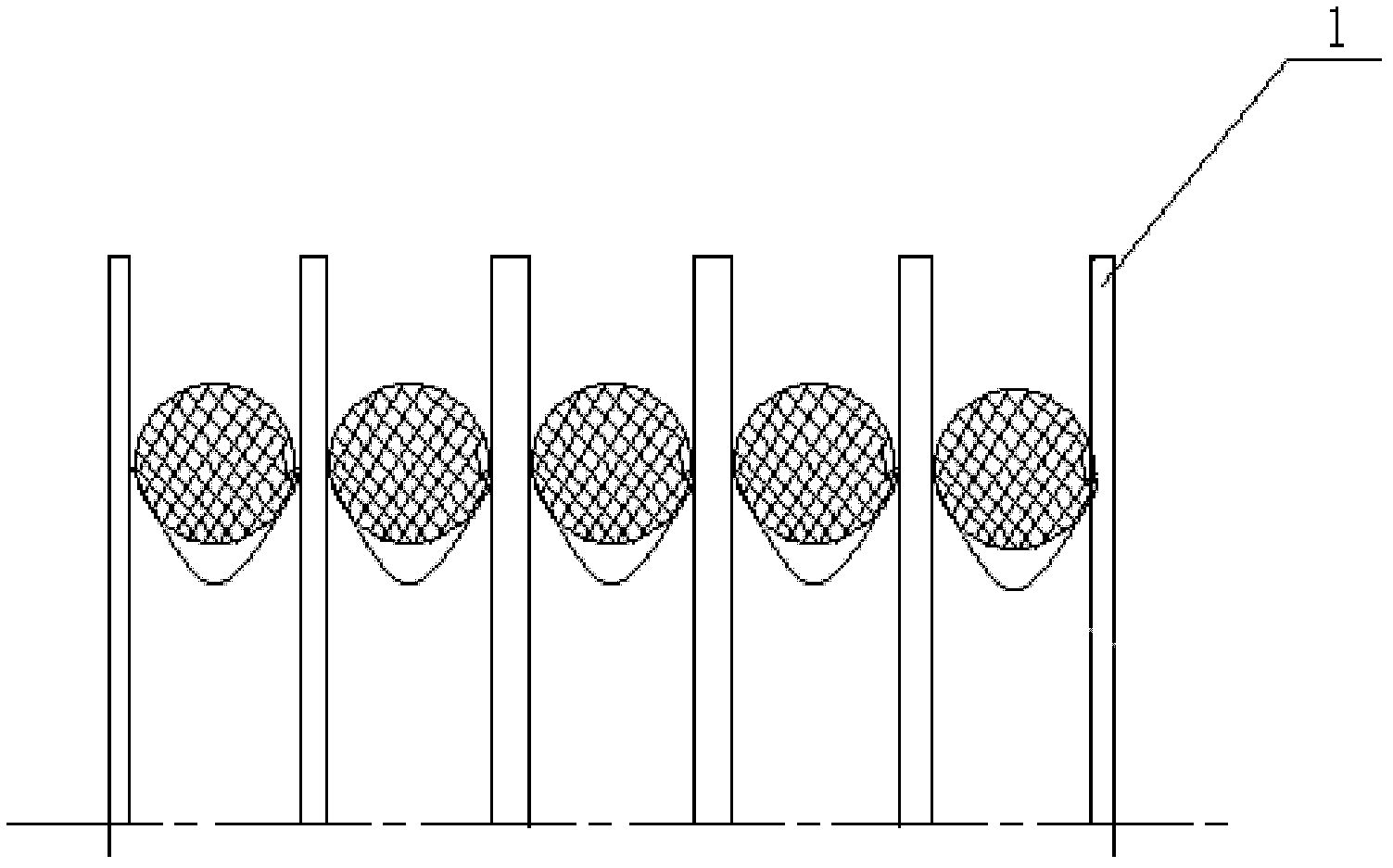

[0016] Such as figure 1 , 2 , Shown in 3, a kind of novel traction machine braking device comprises traction wheel 1, braking device, motor 2 and frame 3, and traction wheel, braking device and motor are installed on the frame respectively; Traction wheel The height of the groove walls on both sides of the rope groove is at least not less than the width of the groove; the braking device is arranged outside the traction sheave.

[0017] Further, the traction wheel is integrally formed, and the height of the groove wall is 5mm larger than the width of the groove.

[0018] The brake device is a brake 4 and a brake lining 5 connected to the brake, there are two brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com