Servo motor type undercarriage retractile follow-up loading system and loading method of loading system

A servo motor and follow-up loading technology, applied in the field of landing gear testing, can solve the problems of limited travel of the loading actuator, inaccurate force model, and low speed of the loading actuator, and achieve enhanced safety and reliability. The effect of weakening the degree of oscillation and improving the loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

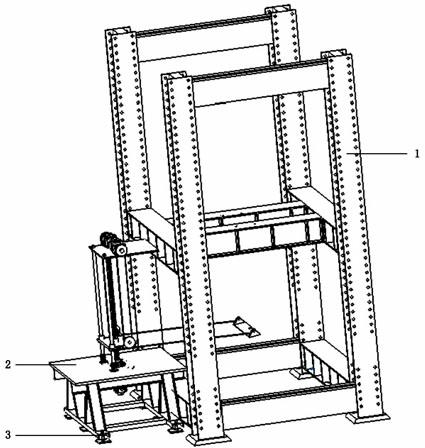

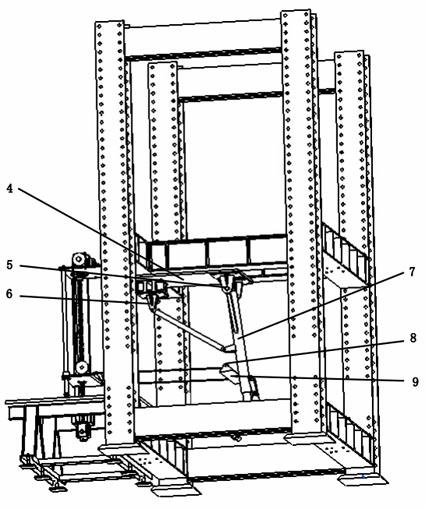

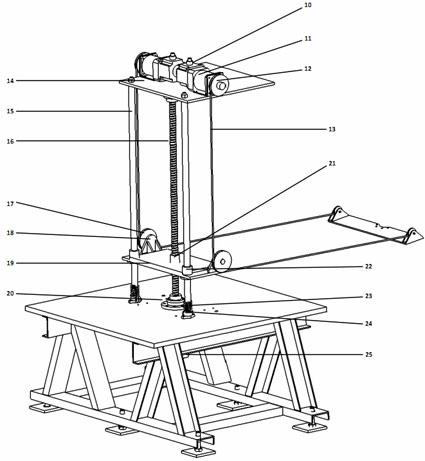

[0031] The servo motor type undercarriage retractable follow-up loading system and its loading method of the present invention:

[0032] It includes the test bench 1 fixedly installed on the test ground, the hanging plate 4 installed on the test bench 1, the main pillar fixture 5 and the retractable actuator fixture for clamping the landing gear 7 are installed on the lower surface of the hanging plate 4 6. Consists of a clamping and bearing mechanism; it also includes a support frame 2 fixedly installed on the test ground, a ball screw 16 installed on the support frame 2, the lower end of the ball screw 16 is connected with the output shaft of the vertical servo motor 25, and the installation The lifting table 19 that follows the ball screw 16 and the vertical guide rail 15 constitutes a load direction following mechanism; it also includes a fixed table 14 installed on the upper end of the ball screw 16 and fixed relative to the support frame, fixedly installed on the fixed ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com