Medium goods shelf assembly and motorcycle with same

A technology for motorcycles and shelves, which is applied in the field of middle shelf assembly and its motorcycles. It can solve the problems of modeling design requirements, high requirements for welding and baking paint, exposed torsion spring windings, and scratches on middle shelves, so as to save materials and assemble The effect of simplifying the process and reducing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

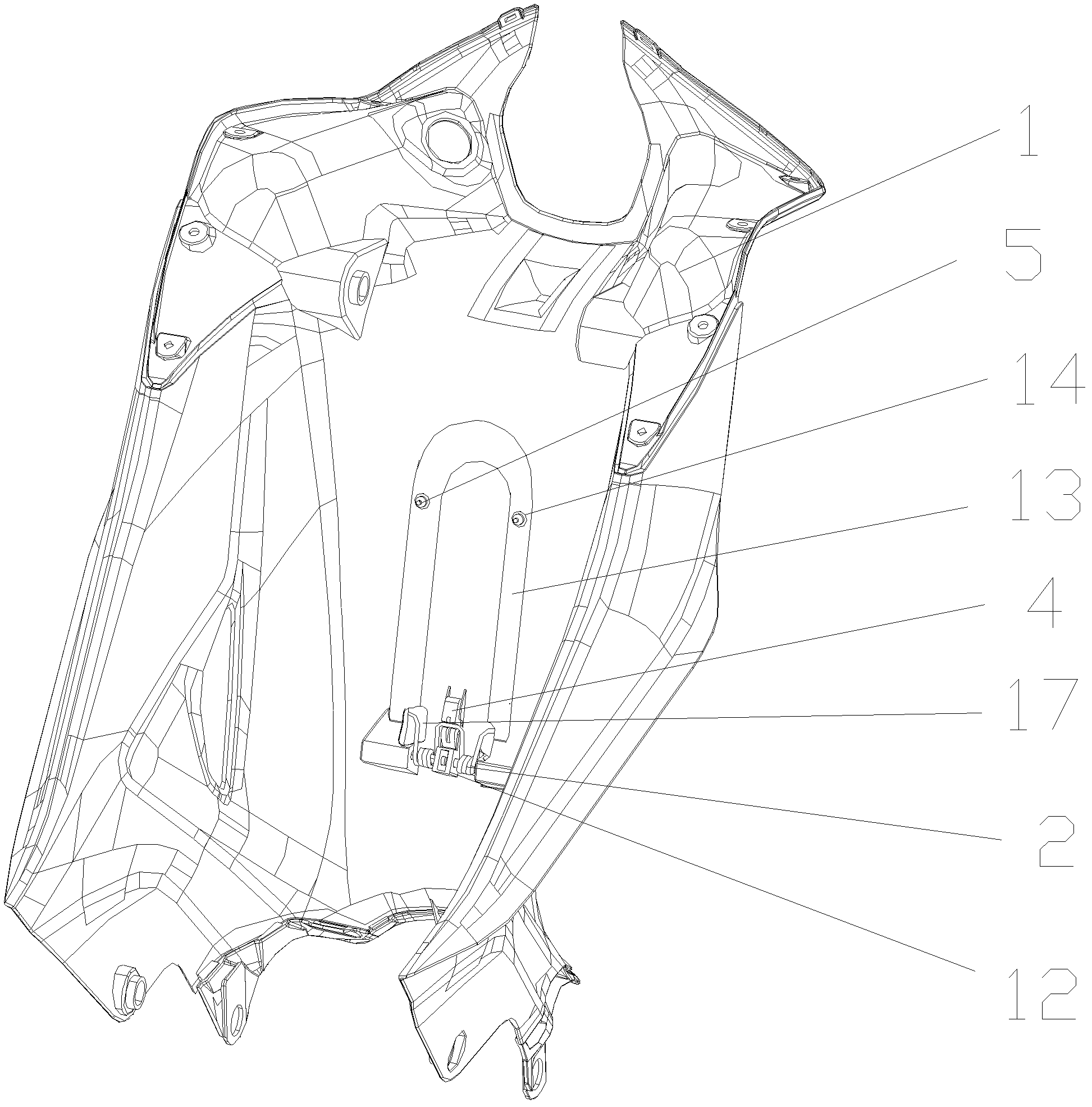

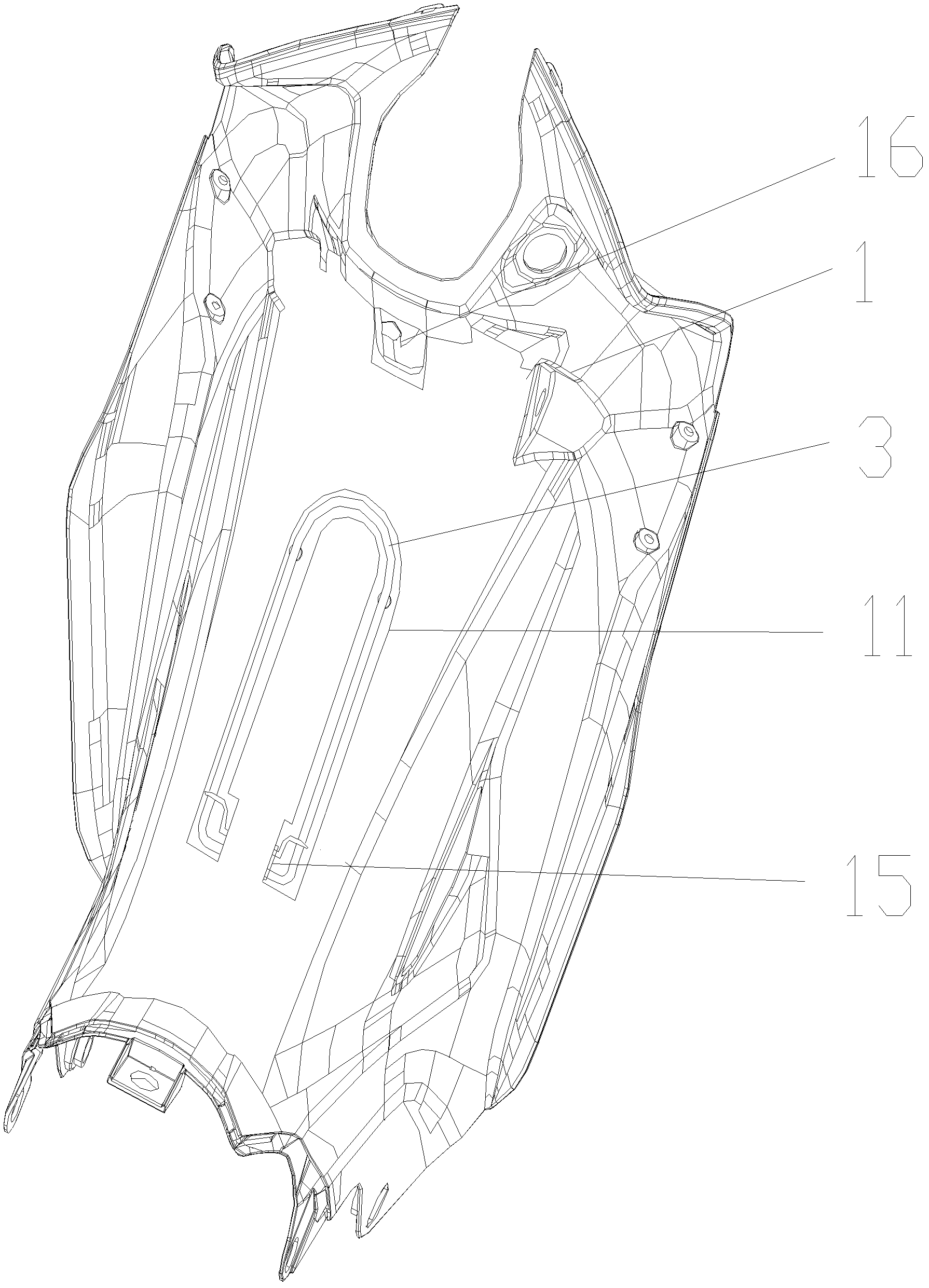

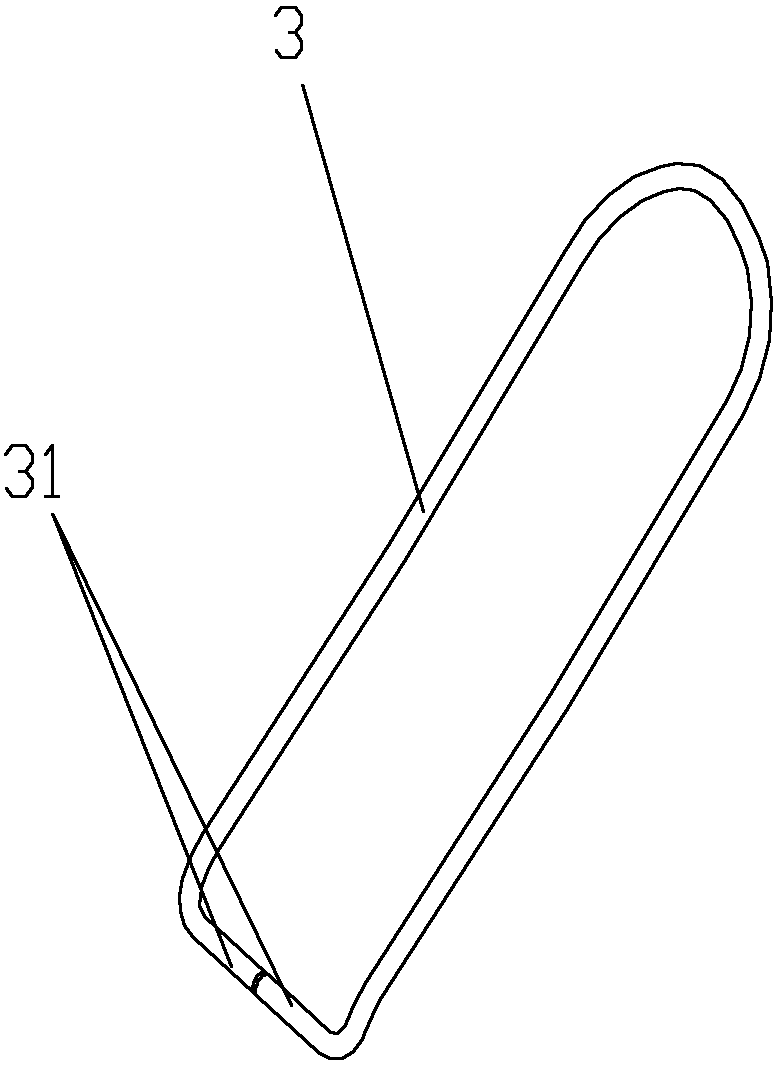

[0024] figure 1 Is a schematic diagram of the lower surface structure of the present invention, figure 2 Is a schematic diagram of the upper surface structure of the present invention, image 3 Is a schematic diagram of the pressure clamp structure of the present invention, Figure 4 Is a schematic diagram of the torsion spring structure of the present invention, Figure 5 It is a schematic diagram of the structure of the torsion spring limit slider of the present invention, Image 6 It is a schematic diagram of the structure of the limit block of the present invention. As shown in the figure, a middle shelf assembly provided by the present invention includes a middle shelf body and a middle shelf base body 1, wherein the middle shelf base body 1 is fixed and covered on a motorcycle curved beam. Motorcycle windshield.

[0025] In this embodiment, the middle shelf body is a pressure clamp 3 elastically hinged to the rear surface of the middle shelf base 1 through an elastic compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com