Line-drawing device of wave-proof board

A wave-proof plate and center line technology, applied in the field of line drawing devices, can solve problems such as the error of fitting the template and the hull, the cumulative error cannot be estimated, and the difficulty of drawing lines with slip needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

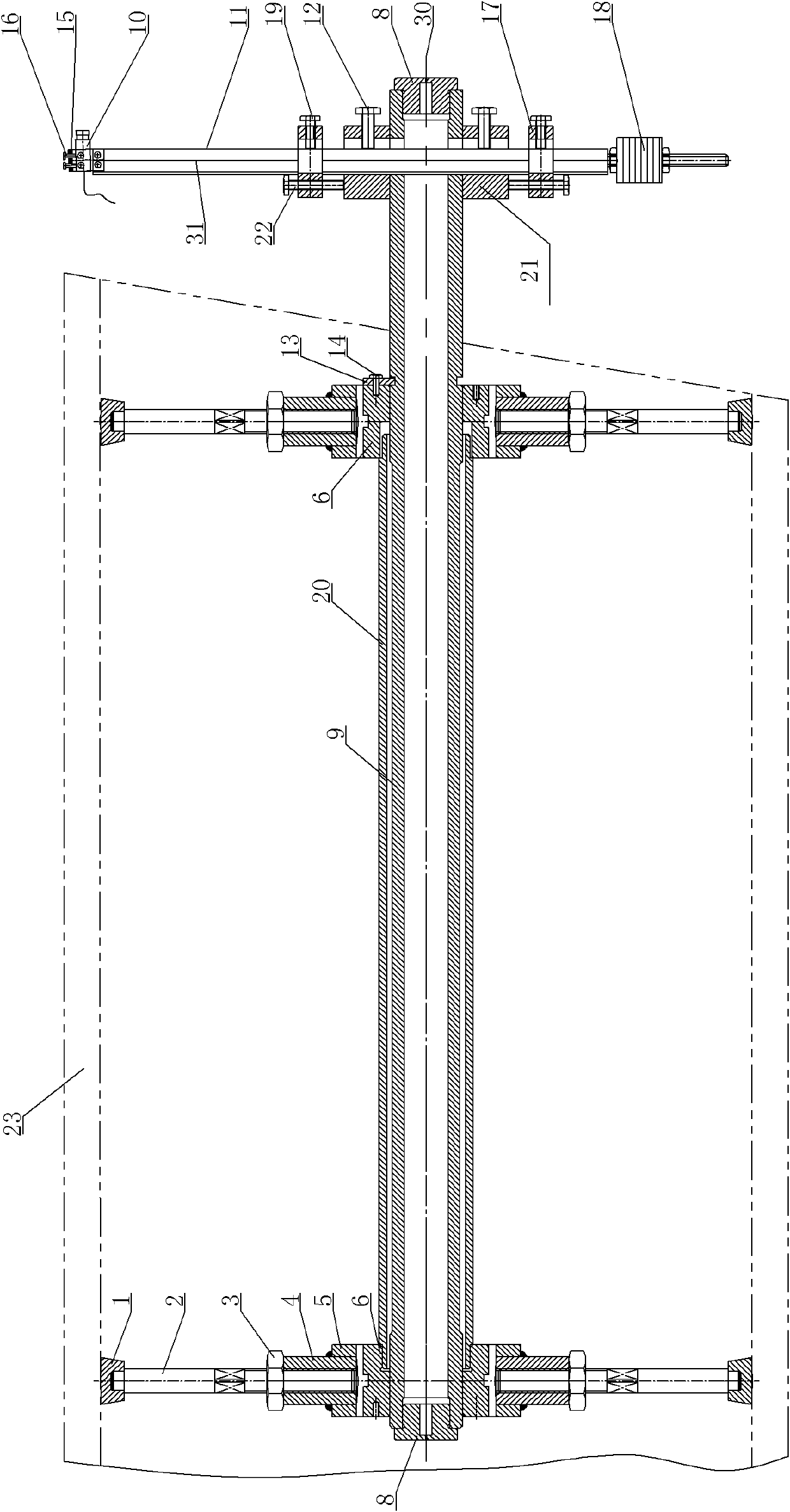

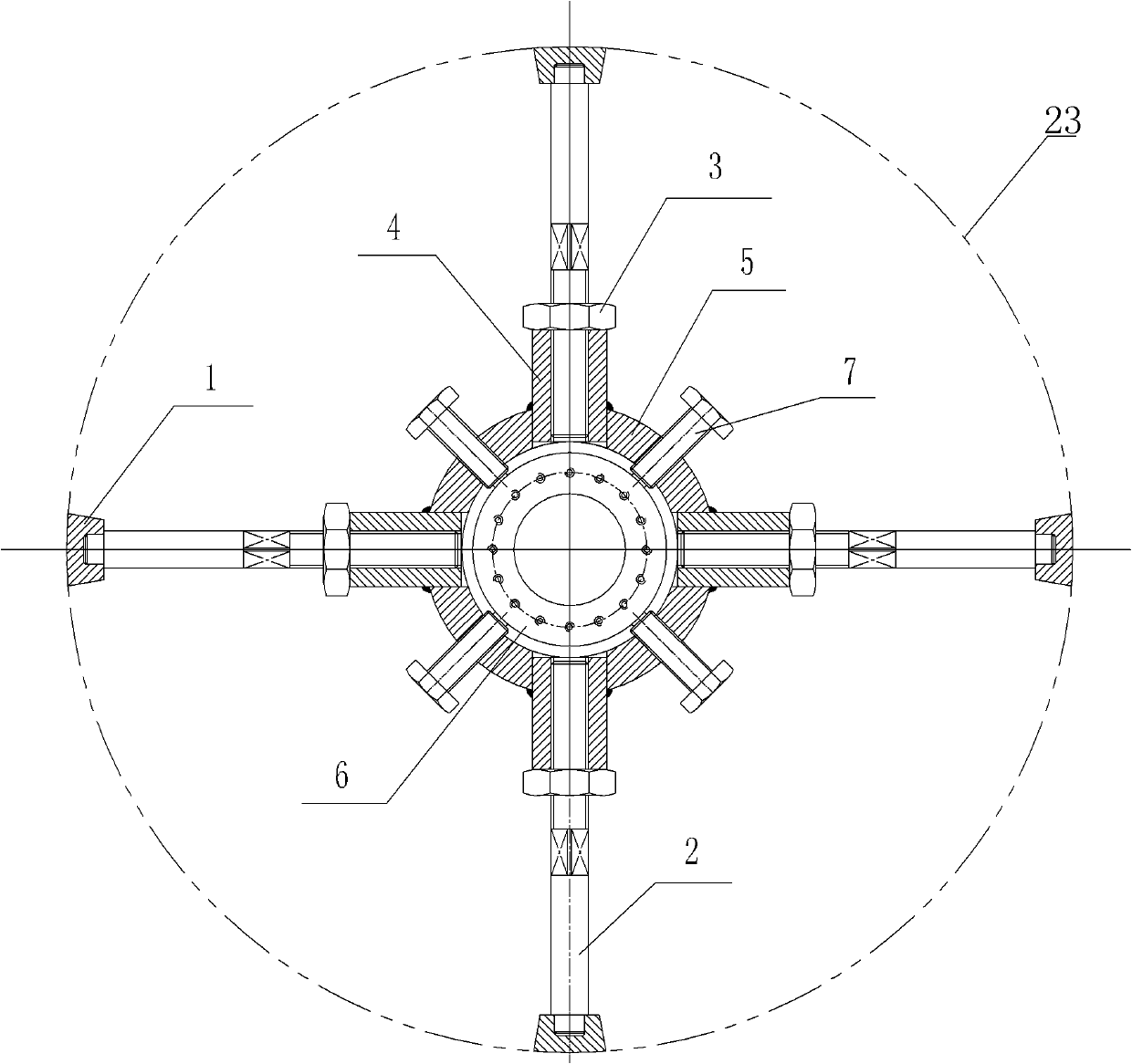

[0030] The appearance of the anti-wave board is formed as figure 1 shown. The outer shape of the anti-wave plate is formed by the intersection of the taper line 100 released from the centerline surface of the front cover of the circular tube 23 and the complex curved surface 102 of the hull, and the intersection line is the outer shape curve 101 of the anti-wave plate. There is a distance from the nozzle to the curved surface 102 of the hull, which is about 2 meters. This distance is relatively long, and it is difficult to achieve the desired effect by using the traditional needle drawing method.

[0031] The anti-wave plate line drawing device of the present invention can solve the above problems, and can place taper lines and draw lines at a long distance.

[0032] See Figure 2-3 , is a schematic structural diagram of the line drawing device involved in the present invention. It includes a positioning assembly fixed in the circular tube 23 and a rotating shaft 9, the rot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap