Vibrating tactile interface

A kind of interface and tactile technology, applied in the direction of instrument, electrical digital data processing, user/computer interaction input/output, etc., can solve the problems of large volume and limited detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

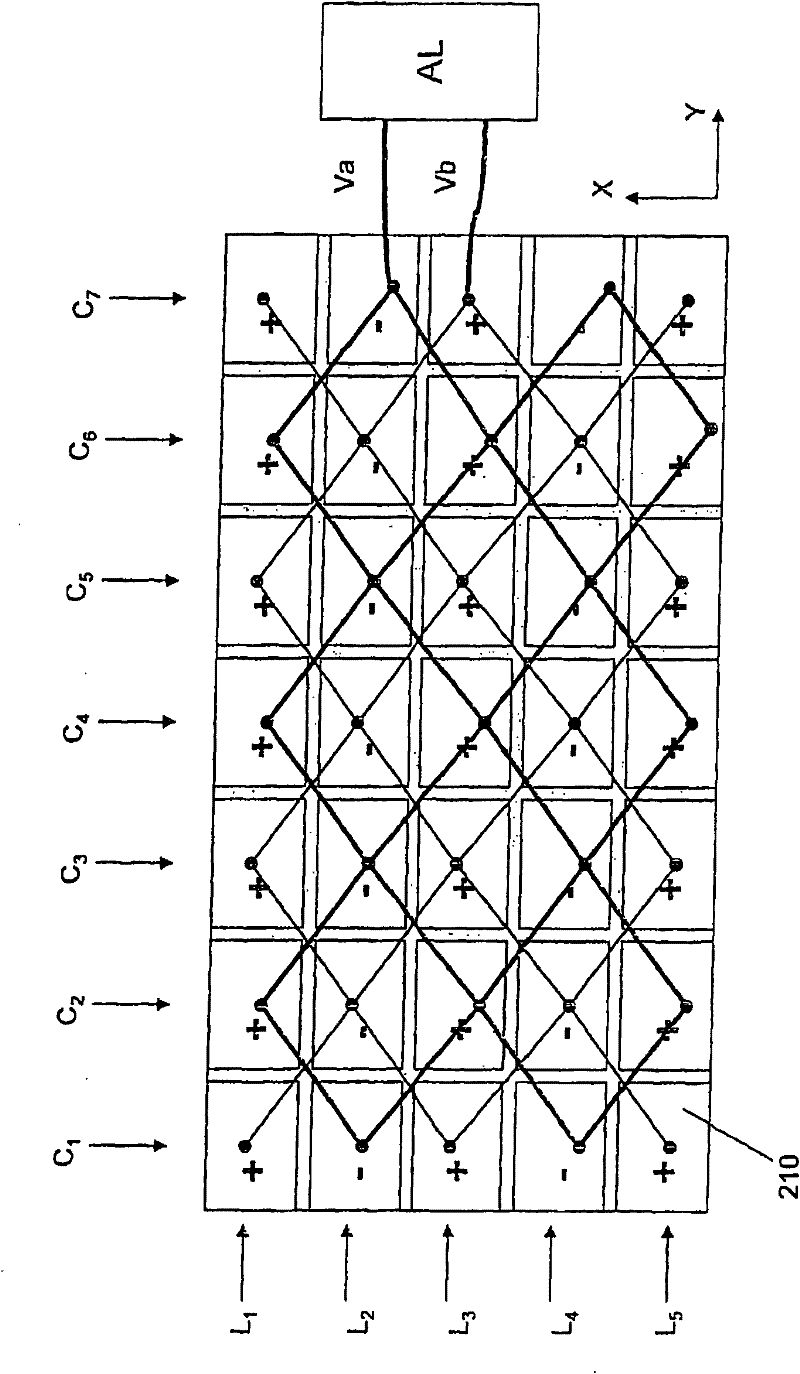

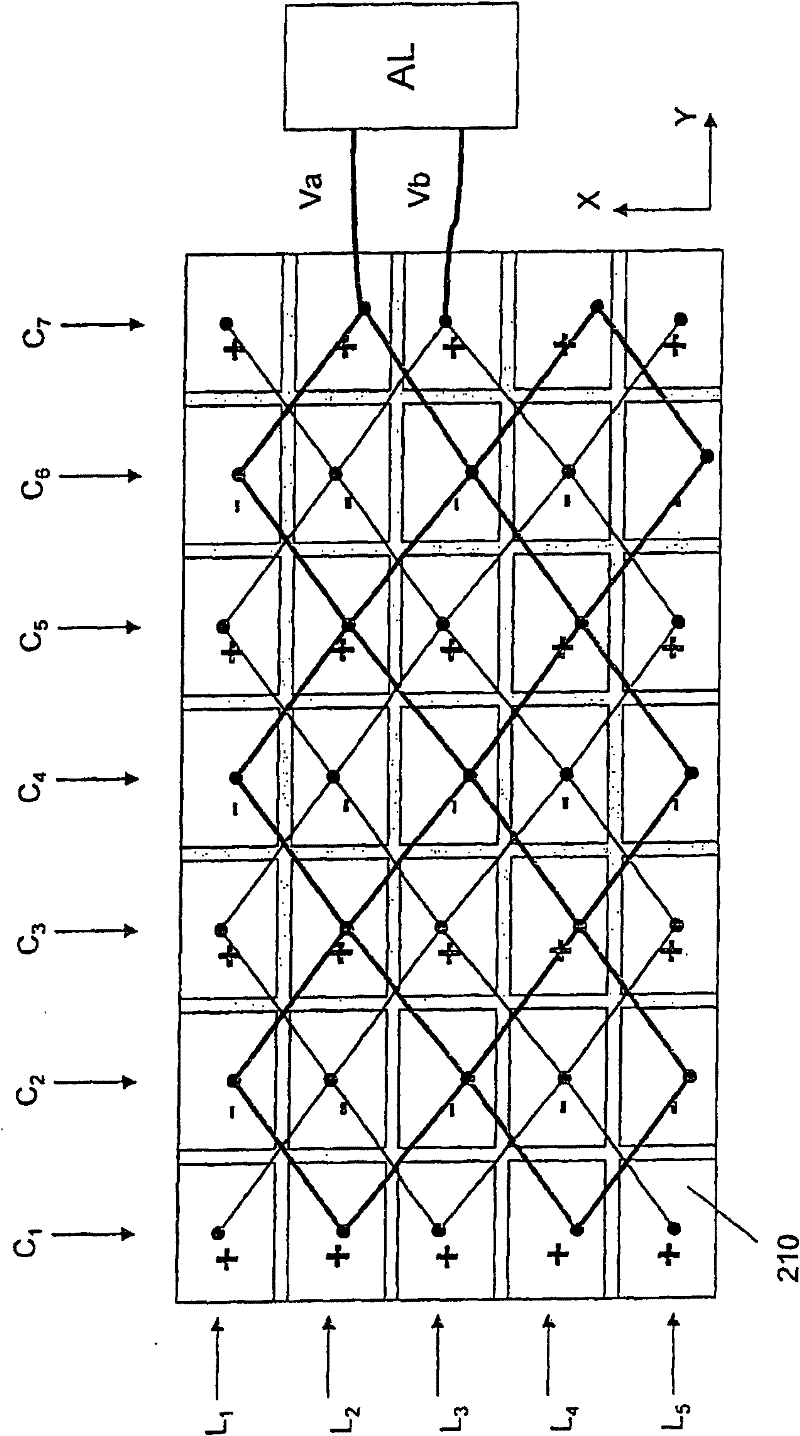

[0059] In a specific embodiment given only as an indication, the resonant base 20 is a thickness (e 1 ) equal to 2mm, length L equal to 83mm, width (I) equal to 49mm beryllium copper plate. Each piezoelectric ceramic element 210 is a 11mm * 9mm, thickness (e 2 ) is equal to a rectangular plate of 1 mm. These piezoelectric ceramic elements 210 are fixed on the board 20 with epoxy glue. The frequency f of the intrinsic bending mode along the propagation axis Y Y is 30.5kHz; the frequency f of the intrinsic bending mode along the propagation axis X X 44.8kHz.

[0060] Bending mode along length L (axis Y) / Figure 6

[0061] Figure 6 An example of deformation of the contact surface 20a of the interface 1 along the longitudinal propagation axis Y is shown. The deformation is measured point by point by a laser vibrometer. To obtain this deformation, the signal V a and V b Has the following characteristics:

[0062] V a = V1.sin(ωt), V b =V1.sin(ωt-π)

[0063] Exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com