Device and method for carrying out thermocompression welding on enameled wires of pendulum components

A technology of hot-press welding and pendulum components, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency, difficult to guarantee the quality of solder joints, difficult operation, etc., and achieve yield and work efficiency Improvement, welding parameters are stable and controllable, and the effect of improving tensile and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

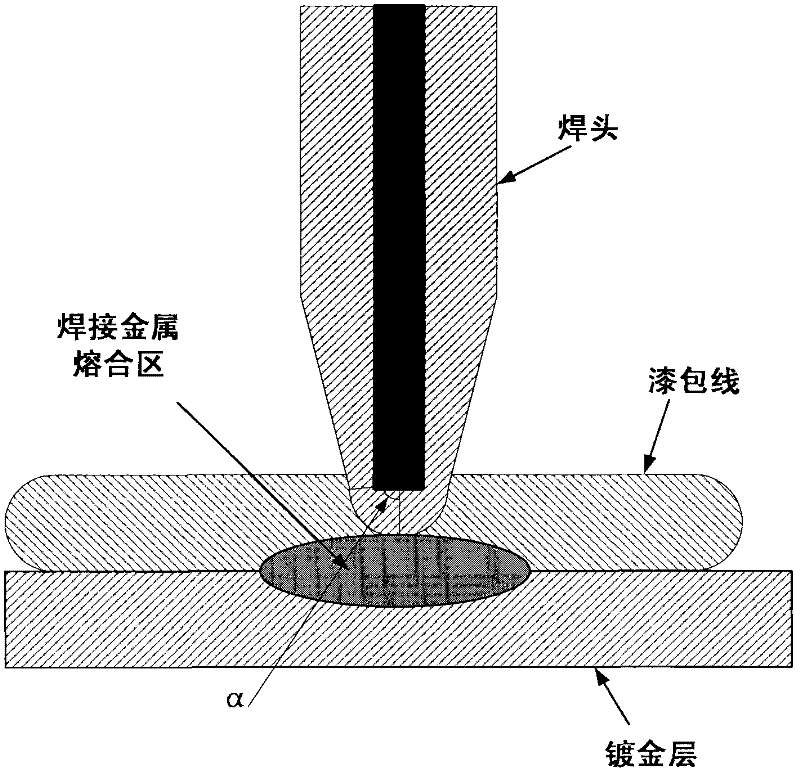

[0027] The present invention as Figure 4 shown in the following steps:

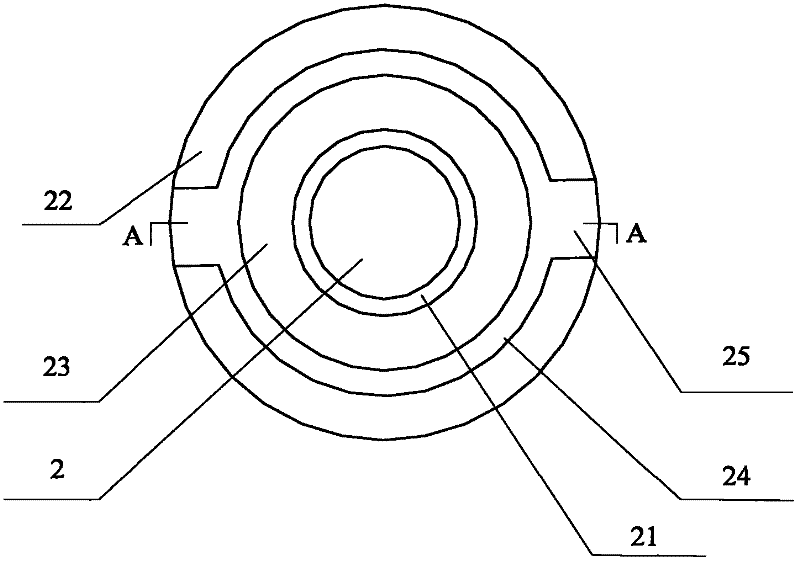

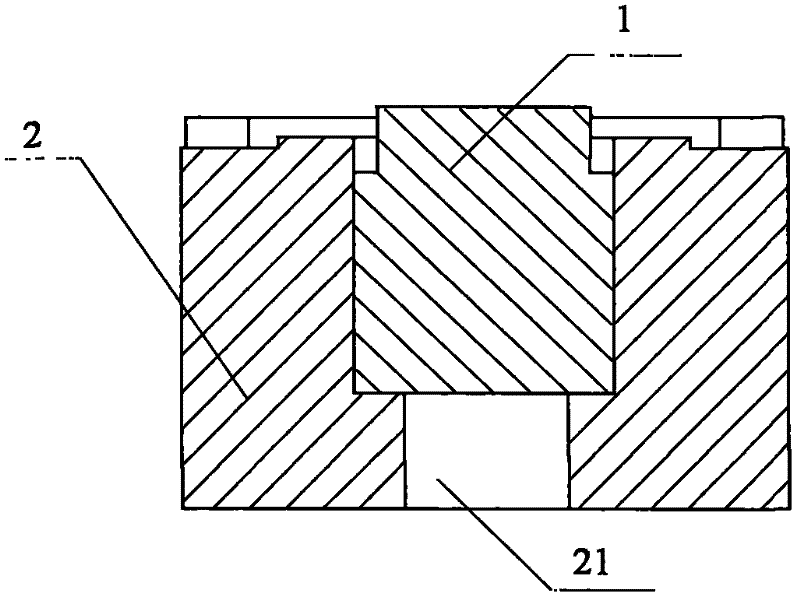

[0028] 1. Make welding device

[0029] The device for thermocompression welding of enameled wire of pendulum components such as figure 1 , 2 The figure includes a base 1 and a sliding shaft 2, and the sliding shaft 2 and the base 1 are separate structures. The base 1 is cylindrical, and the central position is processed with a stepped hole 21 through which the large-diameter hole at the top of the stepped hole 21 is a sliding shaft installation hole, and the small-diameter hole at the bottom is an air hole. The sliding shaft 2 is a cylindrical stepped shaft, the large diameter part is matched with the large diameter hole of the stepped hole 21, the small diameter part is matched with the inner diameter of the torque device moving coil, the sliding shaft 2 is coaxial wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com