Sand-like strong alkali metal filtering washing system and washing process

A strong alkali metal and cleaning system technology, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of low safety, poor separation effect of separation equipment, high activity, etc., achieve good separation effect, improve washing effect, Guarantee the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

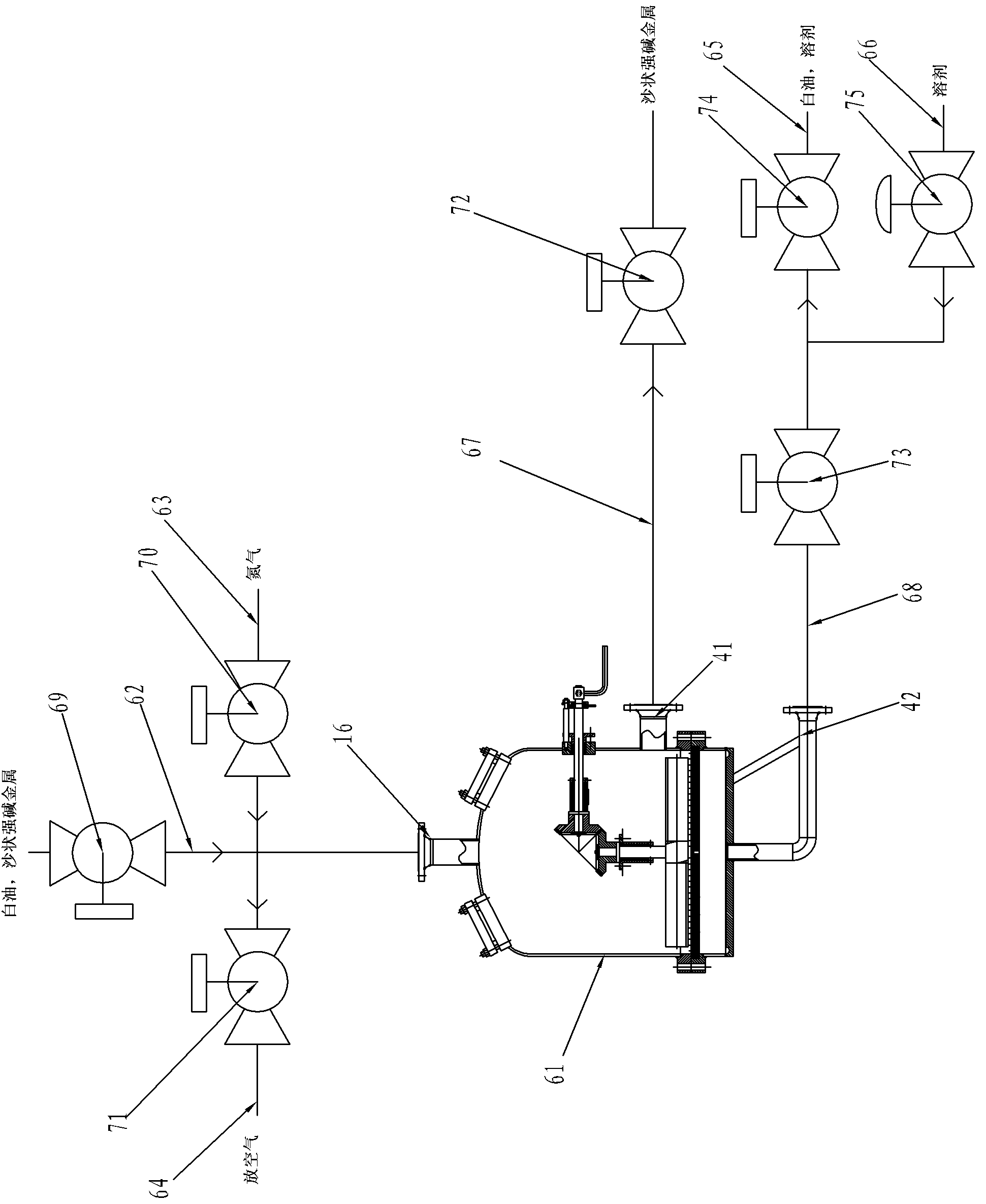

[0024] Such as figure 1 As shown, the sandy strong alkali metal filter cleaning system of the present invention includes cleaning equipment 61, feed pipeline 62, air intake pipe 63, vent pipe 64, white oil and solvent discharge pipe 65, and solvent flushing pipeline 66.

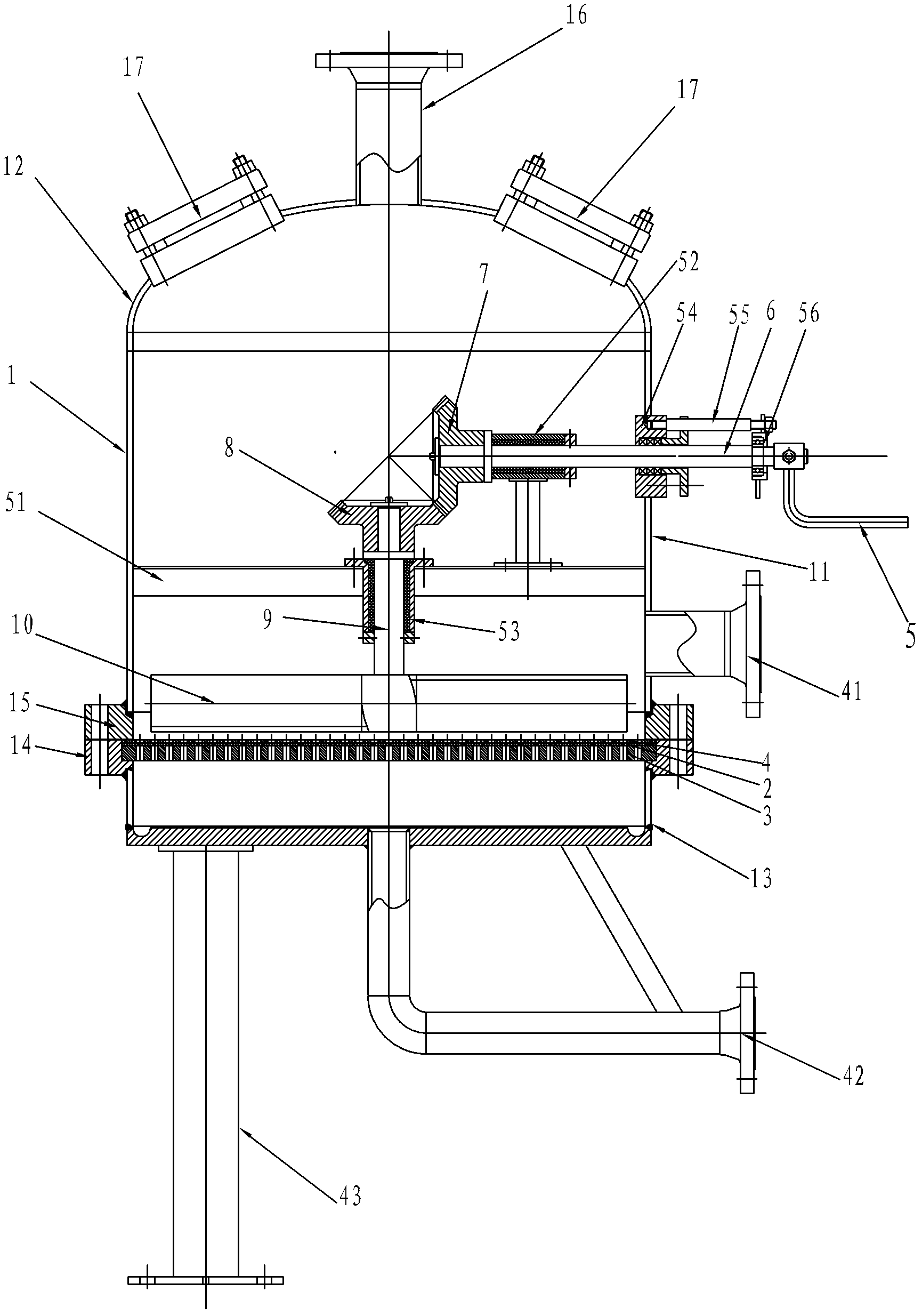

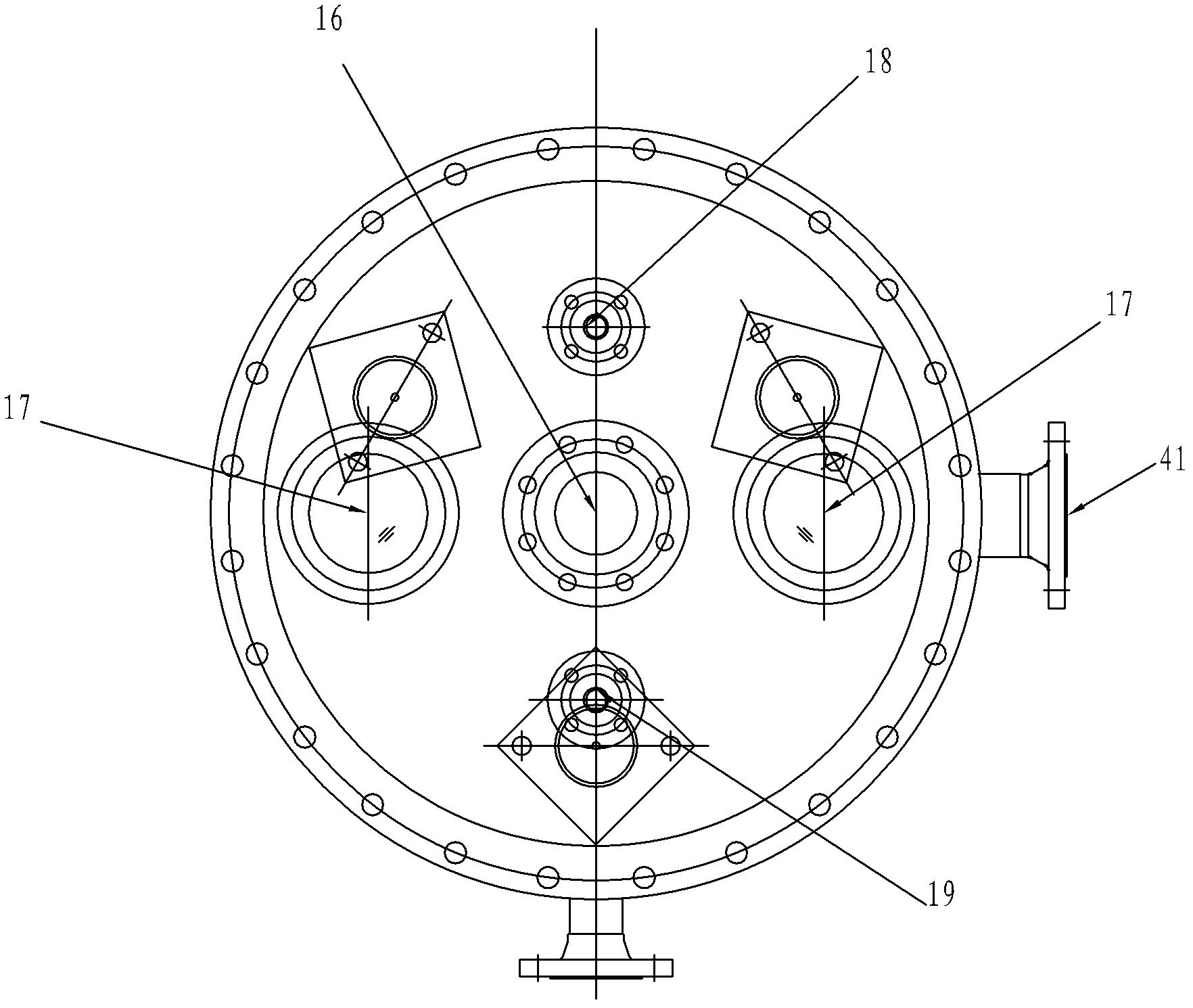

[0025] combine figure 2 , 3 As shown, wherein the cleaning equipment includes a tank body 1, an agitator, and a filter assembly, the tank body 1 includes a shell 11, a top head 12 and a bottom head 13, the top head 12 is an elliptical head, and the bottom head 13 is Flat bottom or oval head. The bottom head 13 is connected to the upper flange 15 welded at the bottom of the shell 11 through the lower flange 14 . A material inlet 16 is provided at the center of the top head of the tank body 1, and a mirror port 17 is respectively provided on the left and right sides of the material inlet 16. The sand-like strong alkali metal entering the equipment has a very high activity and needs to be isolated from the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com