Guy rope dropping connector

A technology of connectors and threaded connection sleeves, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problem of long connector length, etc., and achieve the effect of stable structure of parts and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

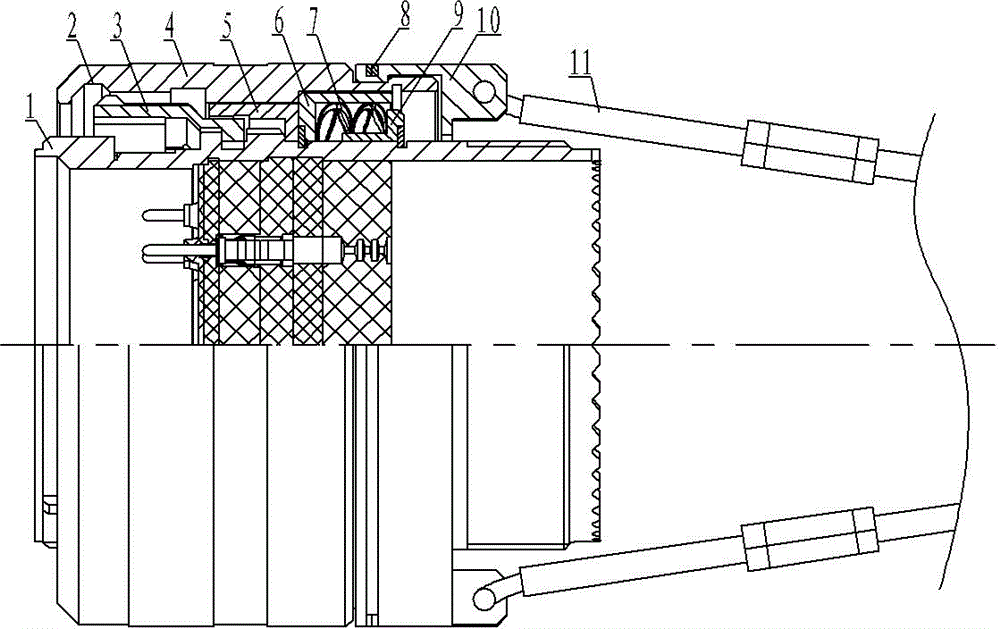

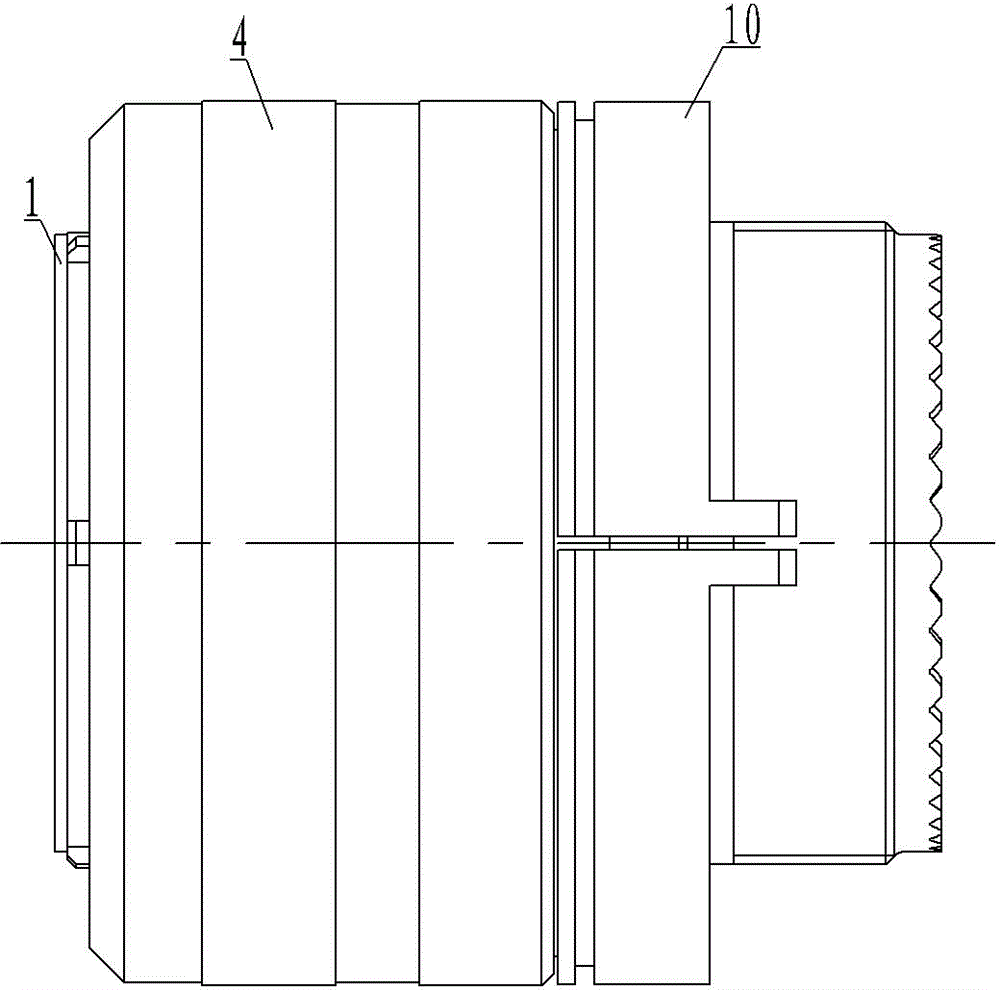

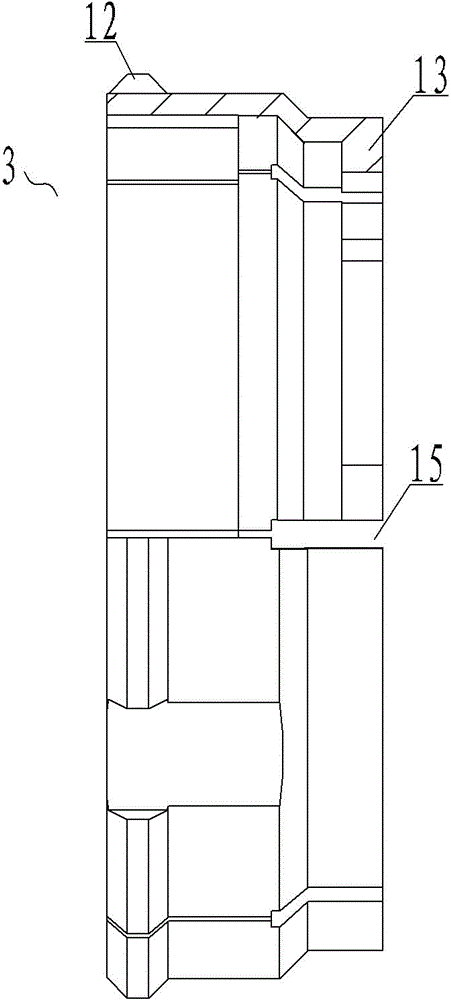

[0038] An embodiment of a pull cord drop connector, in Figure 1~23 Among them, the connector housing 1 has an inner hole passing through the front and back, and the inner hole of the connector housing 1 is provided with a contact piece through an insulator. The outer circumference of the connector housing 1 is provided with a pull-off housing 4, and a threaded connection sleeve 3 is arranged between the front section of the inner hole of the pull-off housing 4 and the connector housing 1, and the rear end of the threaded connection sleeve 3 has The fixed edge 13 turned inward is provided with a front collar 17 and a rear collar 18 at intervals on the outer peripheral surface of the connector housing 1, and the fixed edge 13 is between the front and rear two collars, and its front end surface is in contact with the front collar. The collar 17 stops and fits, and the rear end face and the rear collar 18 stop and cooperate. The front collar 17 and the rear collar 18 prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com