Control device and control method for equipment

A device control and controller technology, applied in electrical components, transmission systems, etc., can solve the problems of inconvenience, limited number of PLC terminals, and inflexible control, and achieve the effects of increasing convenience, improving transparency, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

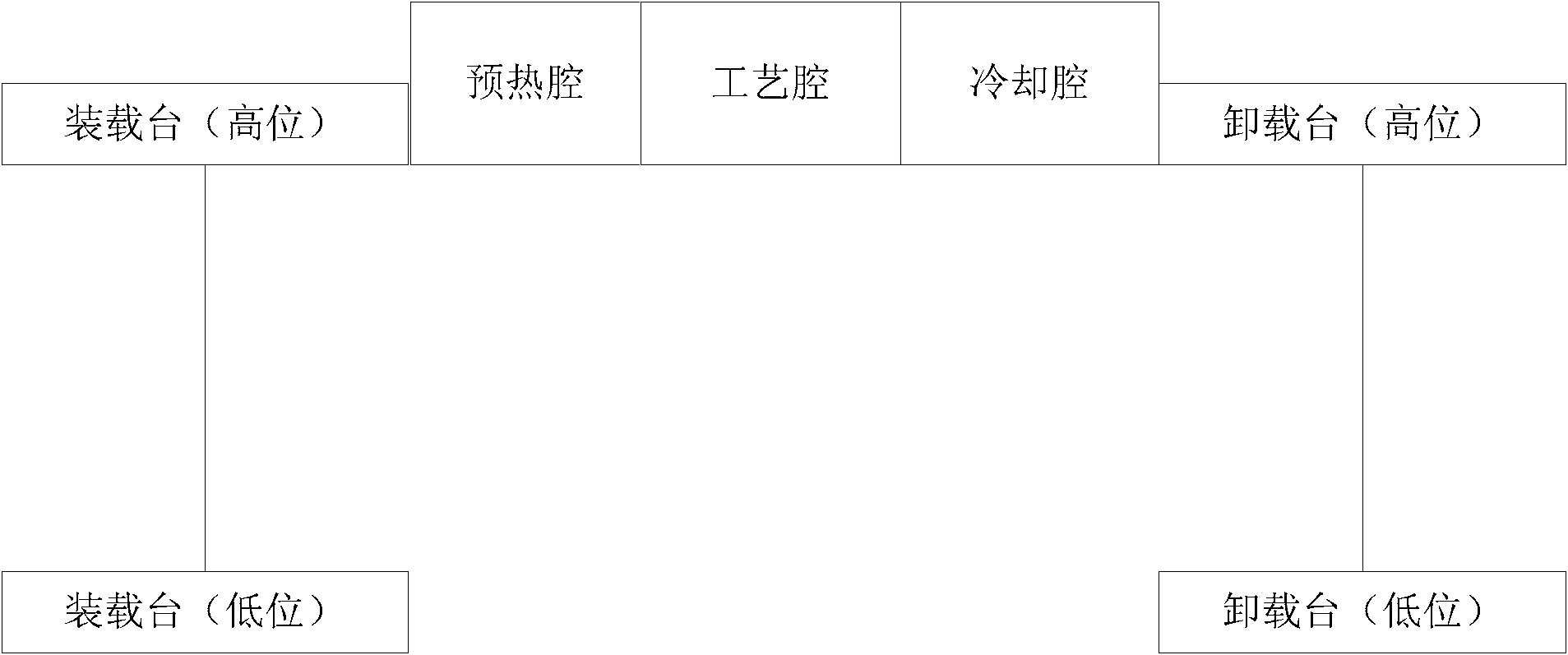

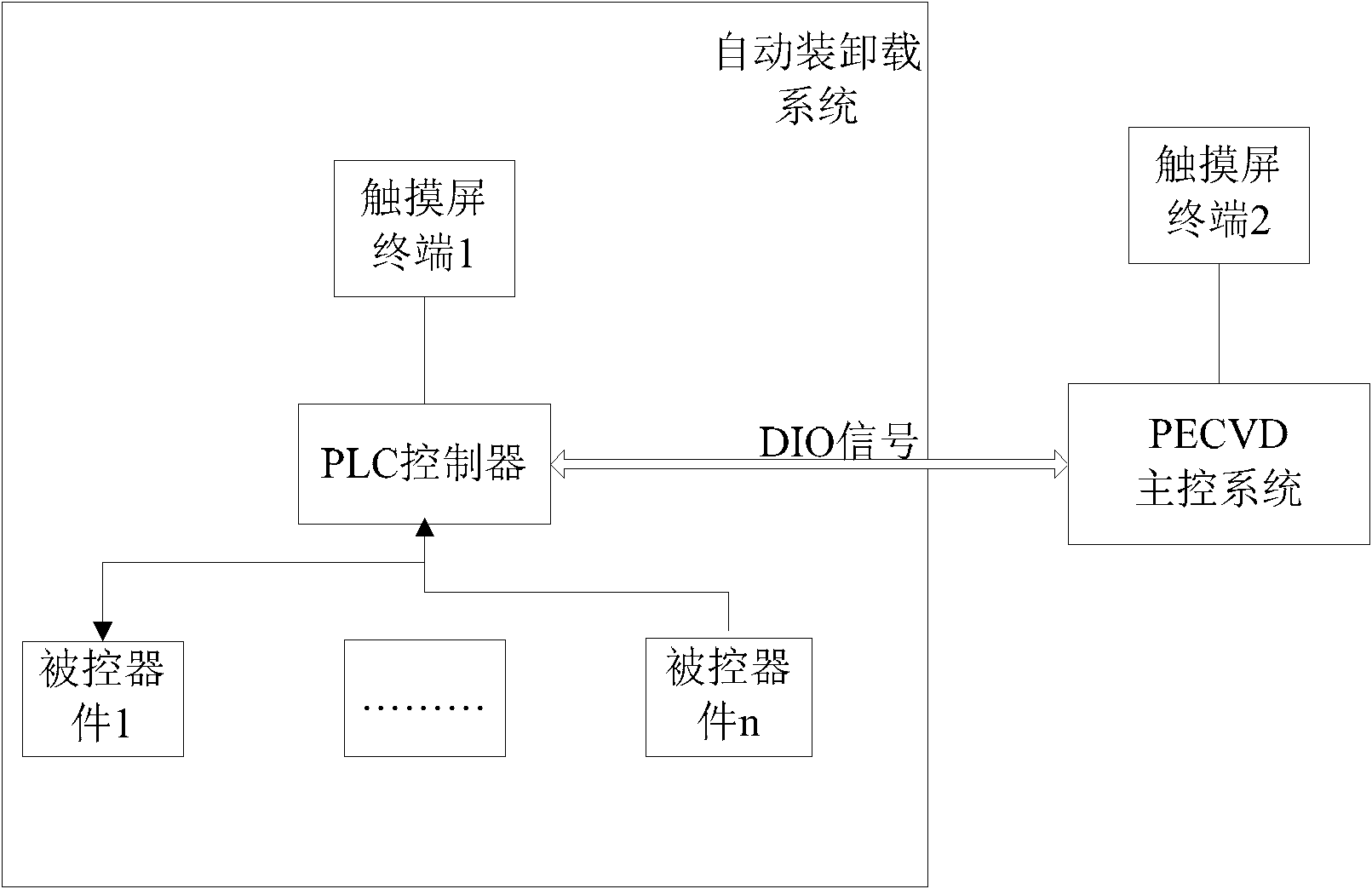

[0081] If the control mode in the existing method of the background technology can be changed, and the control of the loading stage and the unloading stage can be integrated in the PECVD main control system, then the number of touch-screen terminals can be reduced, and the convenience of user operation can be increased; and, if The combination of some basic actions can be realized in the PLC controller to cooperate with the automatic scheduling of the upper-layer software, so that the scheduling will be more flexible without losing the efficiency of the PLC controller.

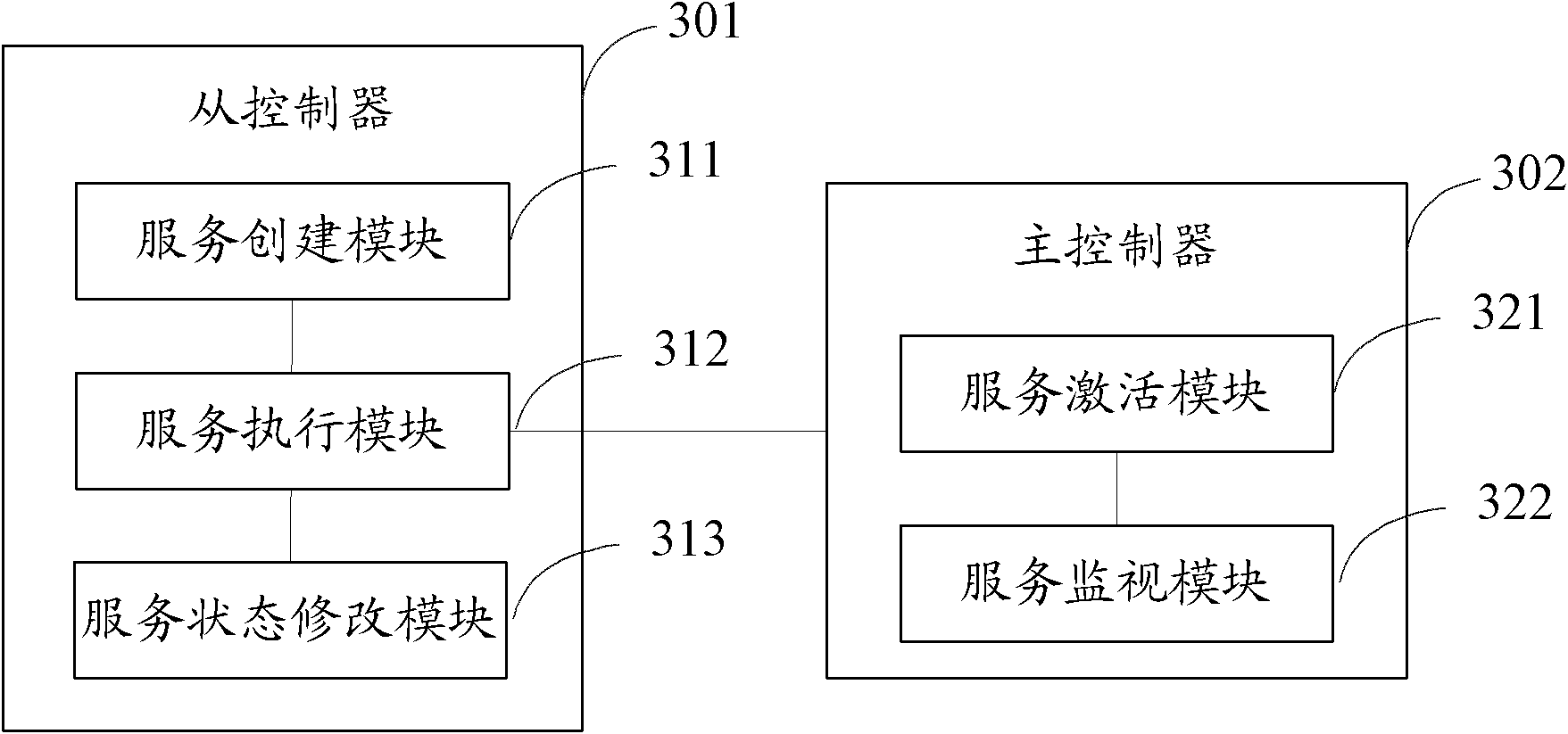

[0082] The inventor of this patent has noticed this point, therefore, creatively proposed one of the core concepts of the embodiment of the present invention, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com