Rotating bracket for wind-tunnel flow-field display test models

A technology of test models and rotating brackets, which is applied in aerodynamic tests, machine/structural component tests, and measuring devices. It can solve the problems of large human injuries, toxicity, and weakness, and achieve improved efficiency and accuracy and simple structure. , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

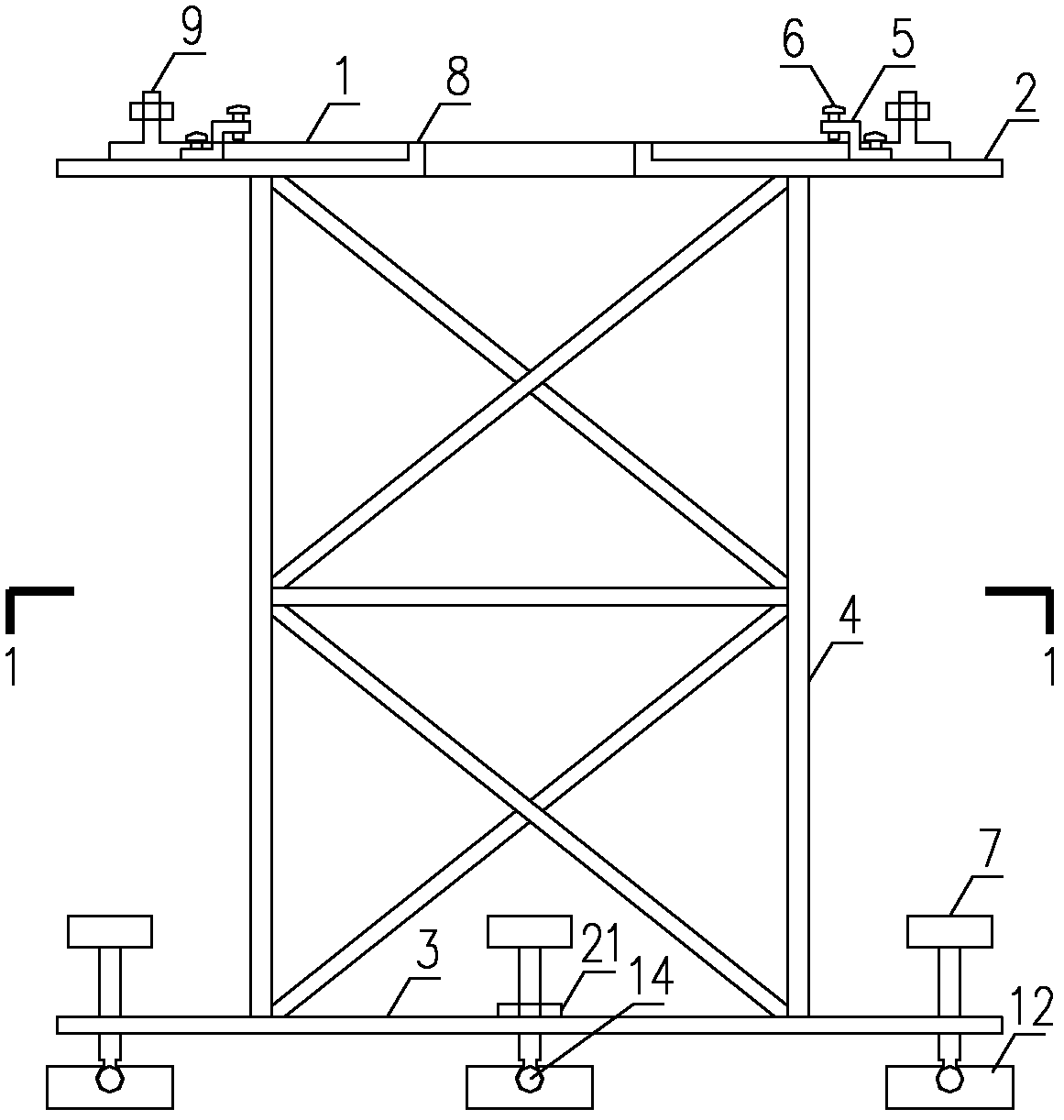

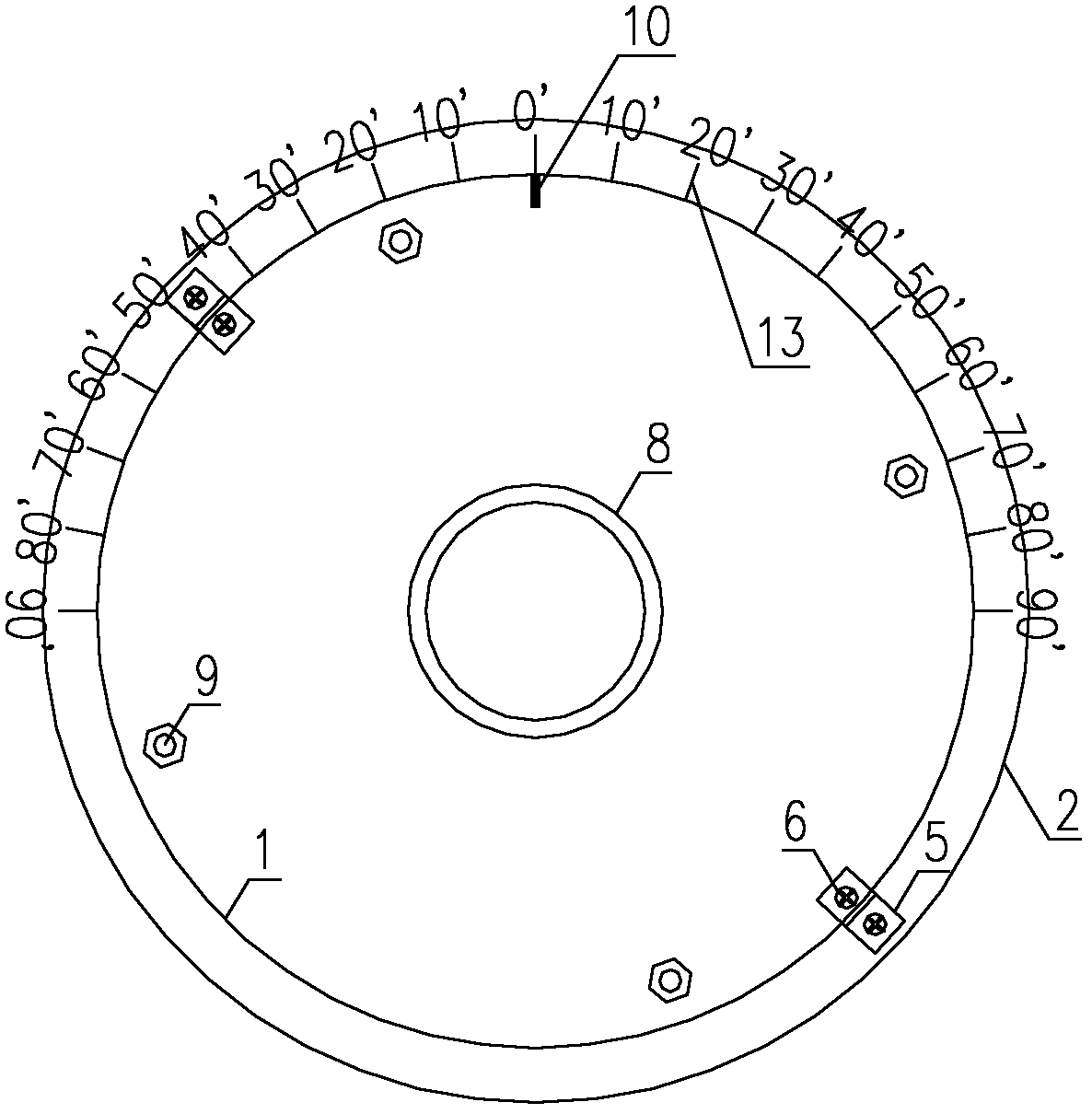

[0026] A wind tunnel flow field display test model rotating bracket, comprising: a bottom plate 3 and a top plate 2 parallel to each other, a supporting truss 4 is provided on the bottom plate 3 and the top plate 2, a central circular hole is provided on the top plate 2, and a central circular hole is A flange 8 is arranged on the circumference, and a rotating plate 1 is set on the flange 8. A scale pointer 10 and a number of model fixing bolts 9 are arranged on the rotating plate 1. Scale line 13 to accurately locate the rotation angle of the model.

[0027] The top plate 2 is provided with a limit button 5, and one end of the limit button 5 is fixedly connected with the top plate 2, and the other end is located above the top surface of the edge of the rotating plate 1, and the limit button 5 is threaded with a limit fixing bolt 6. A first level 21, a second level 22, and a height adjustment bolt 7 are arranged on the bottom plate 3, the first level 21 and the second level 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com