Acoustic testing method for inherent frequency of engine part

A natural frequency and acoustic testing technology, applied in the measurement of resonance frequency, measurement device, measurement of ultrasonic/sonic/infrasonic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

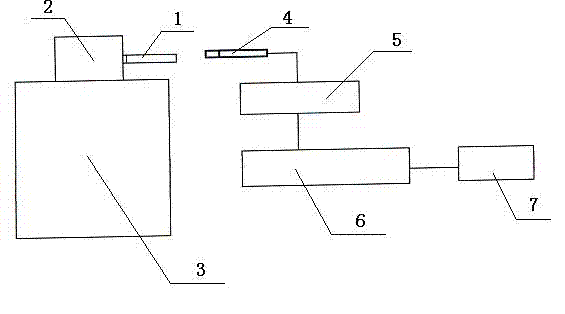

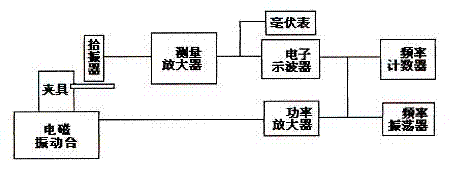

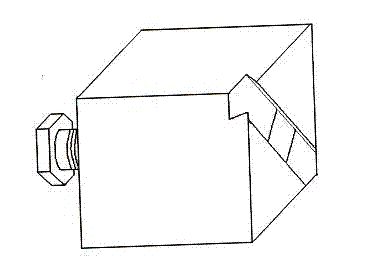

[0035] Use the acoustic method to test the frequency of the high-pressure three-stage working blade of the engine, and fix the working blade A on the working platform with the clamp body and the gantry, and the structure of the clamp body is shown in image 3 , the structure of the gantry see Figure 4; Then, place the microphone MPA401 at a distance of 3cm to 5cm from the blade under test, use a small wooden hammer to vibrate the blade under test, collect the sound waves emitted by the part under test through the sound wave induction sensor, and convert the sound wave signal into a voltage signal through the sensor, and the voltage The signal is amplified by the preamplifier and then transmitted to the signal acquisition processor DH5920, and then the DHDAS signal test and analysis system software in the computer performs self-spectrum analysis on the acoustic digital signal transmitted by the signal acquisition processor to obtain the natural frequency of the working blade. ...

Embodiment 2

[0054] The engine rotor blades B, C, and D are randomly selected as test pieces, and the first three natural frequencies of the blades are tested. The specific test process is as follows. The rotor blades are fixed on the working platform with a clamp body and a gantry, and then the microphone is placed at a distance of At the 3cm~5cm of the measured blade, use a small wooden hammer to vibrate the measured blade, collect the sound wave emitted by the measured part through the acoustic wave induction sensor, convert the sound wave signal into a voltage signal through the sensor, and the voltage signal is amplified by the preamplifier and then transmitted to the The signal acquisition processor, and then through the DHDAS signal test and analysis system software in the computer, perform self-spectrum analysis on the acoustic digital signal transmitted from the signal acquisition processor to obtain the natural frequency of the working blade. The test results are shown in Table 3. ...

example 3

[0061] The natural frequency test of the blisk blade, due to the complex structure of the blisk, cannot be tested by the traditional method, and the advantages of the acoustic method can just meet the natural frequency test of the whole blade, so the acoustic method test of the blisk fills up this technology blank.

[0062] The principle of the test process is as follows: First, use a small wooden hammer to excite the tested component, and then use the acoustic wave induction sensor to collect the excited acoustic wave signal of the tested component, the acoustic signal is converted into a voltage signal by the sensor, and the voltage signal is passed through the front After the amplifier is amplified and adjusted, it is transmitted to the signal acquisition processor, and then the professional signal analysis software (DHDAS signal test analysis system software) in the computer performs self-spectrum analysis on the acoustic digital signal transmitted by the signal acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com