Coplanar sensor and manufacturing method thereof

A manufacturing method and sensor technology, applied in the direction of using electric/magnetic devices to transfer sensing components, manufacturing microstructure devices, piezoelectric devices/electrostrictive devices, etc., can solve the problem of warping and overlapping of fixed arms 52 and extension arms 64 Reduced area, reduced effective capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

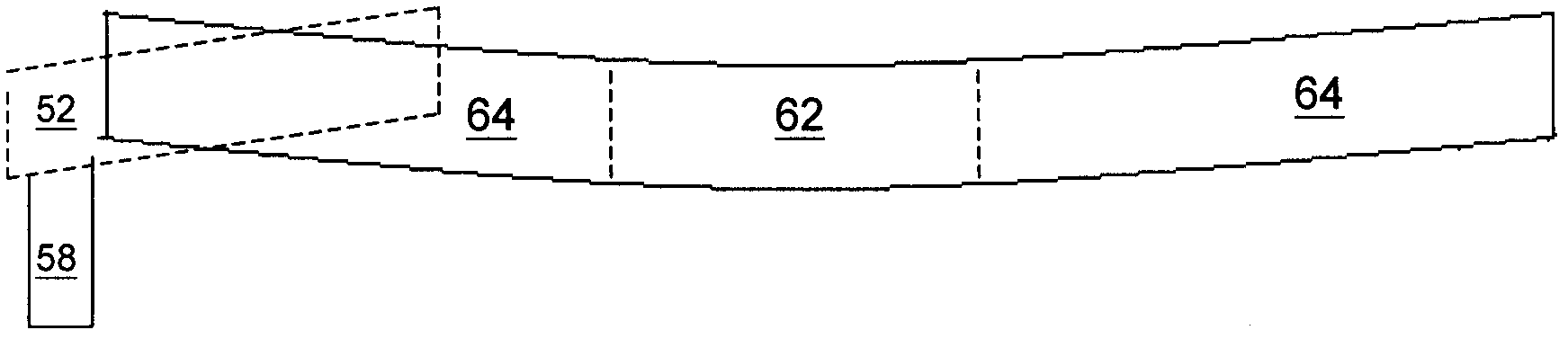

[0059] The icons in this manual are schematic, and their dimensions are not completely drawn to scale.

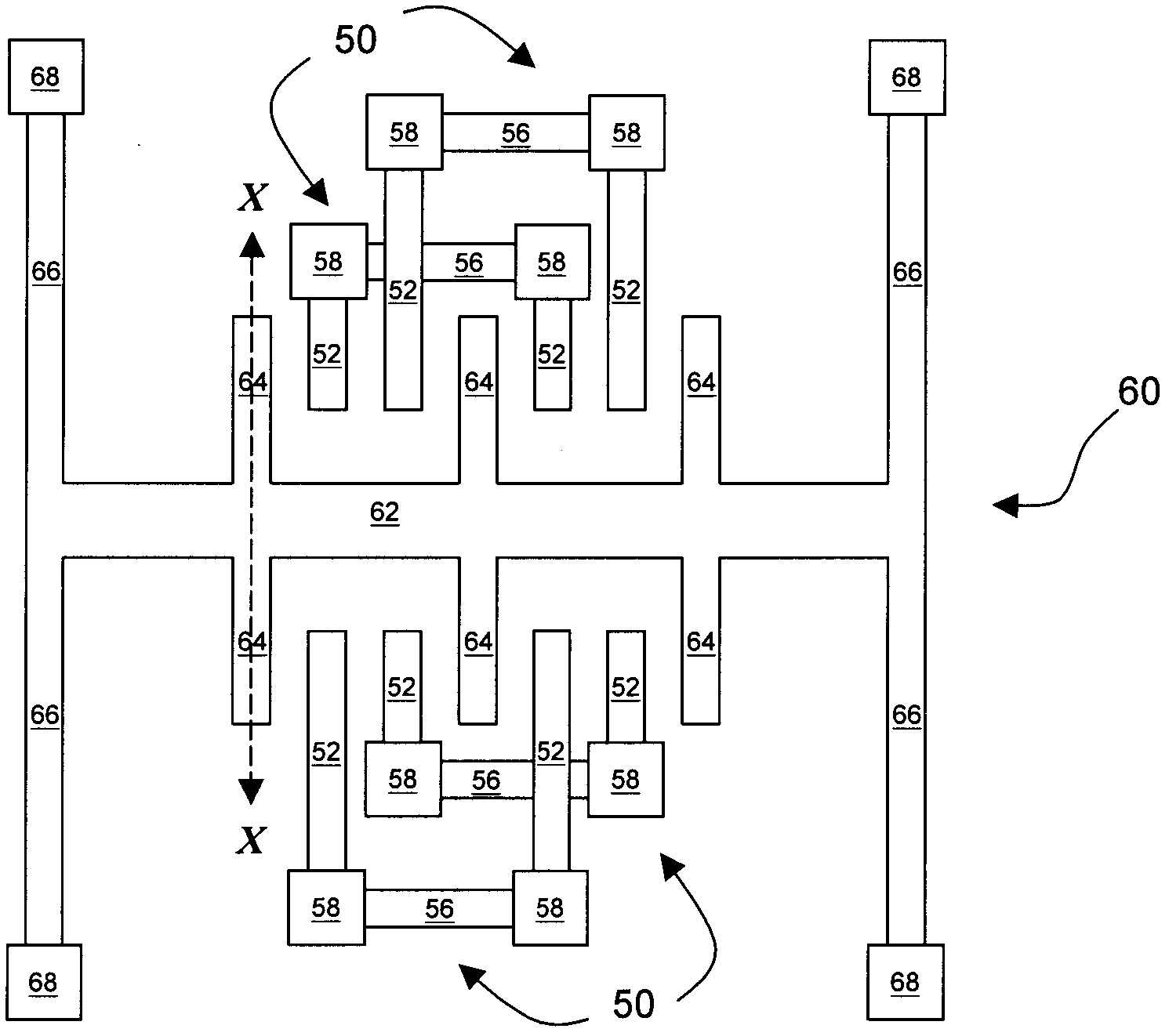

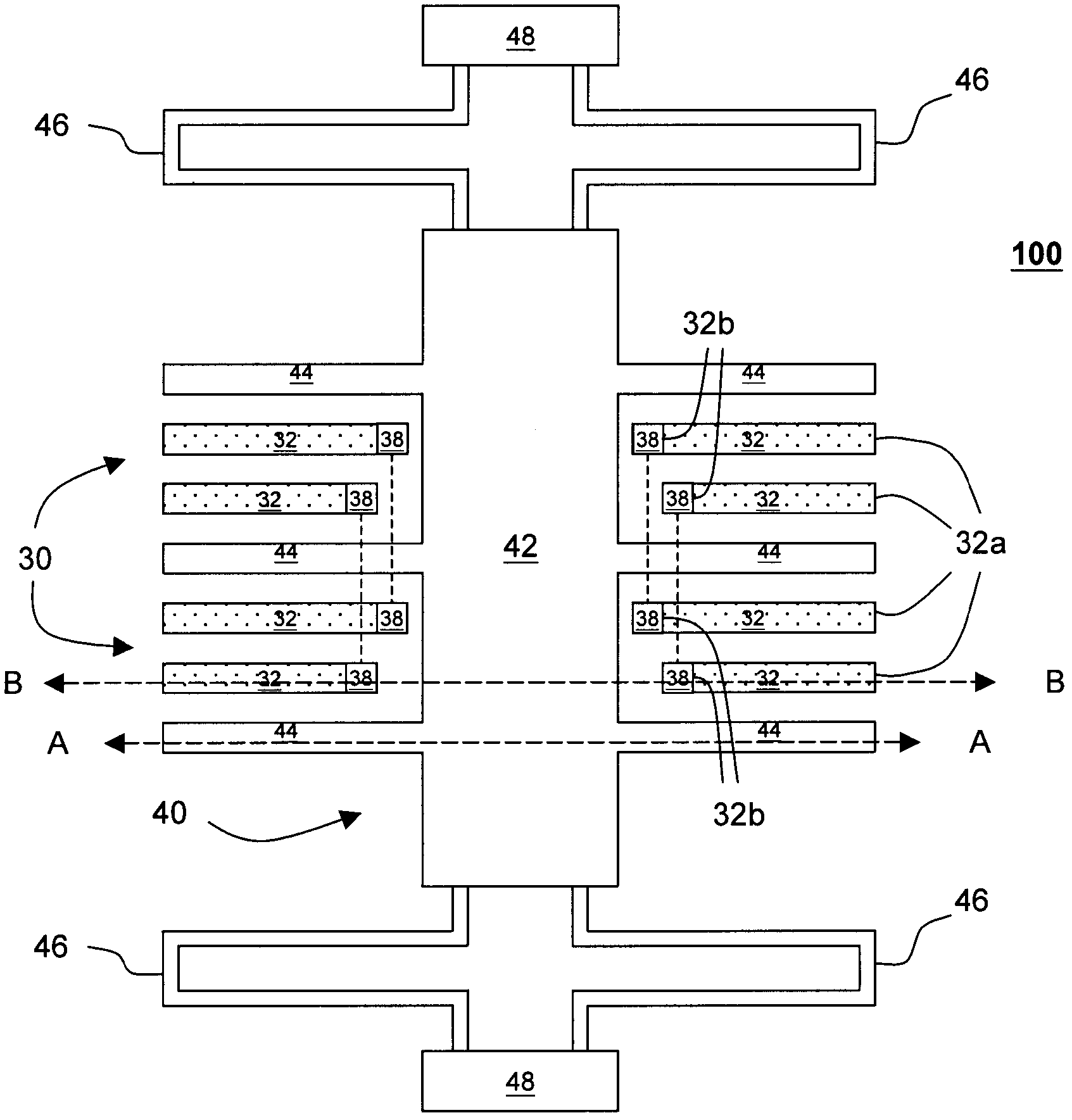

[0060] see image 3, in the first embodiment of the present invention, the MEMS structure 100 of the coplanar sensor includes at least one fixed structure 30 and one movable structure 40 . The moving structure 40 includes a main body 42, an extension arm 44, a connecting portion 46 and a fixed portion 48, which are connected to each other; wherein the main body 42, the extending arm 44, and the connecting portion 46 are suspended structures, and the fixed portion 48 is a fixed structure, which means that except The fixed part 48 is fixed on the lower base (not shown), and the body 42, the extension arm 44 and the connecting part 46 connected to each other are suspended. In one embodiment, the connecting portion 46 is a spring, which can be stretched elastically. The fixing structure 30 includes a plurality of fixing arms 32 . Each fixing arm 32 itself is suspended, and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com