Direct cooling water system for cooling machines

A cooling water system and cooling machine technology, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of complex cooling machine structure, increased factory investment, and inconvenient production and maintenance, so as to facilitate equipment installation and The effects of worker operation, reduced initial investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

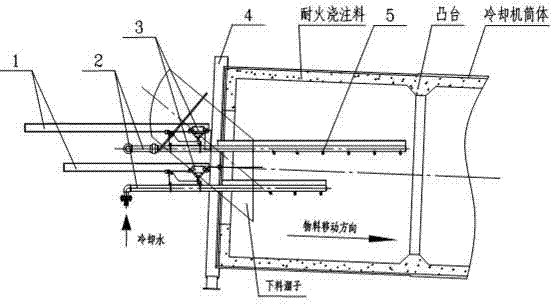

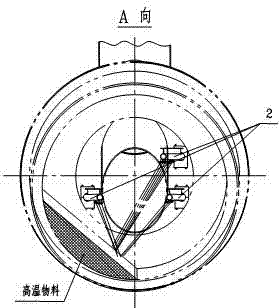

[0009] Embodiment of the present invention: The components of the present invention are: slide rail 1 , cooling water pipeline 2 , pulley 3 , tail cover 4 , nozzle 5 . The slide rail 1 is fixedly installed, and the cooling water pipeline 2 extends into the cylinder body of the cooler through the opening on the tail cover 4, and several nozzles 5 are installed in the cylinder body part. The outer part of the cylinder of the cooling water pipeline 2 is connected with the pulley 3 and installed on the slide rail 1 . The cooling water pipeline 2 and the nozzle 5 can be pulled out from the cooling machine barrel through the slide rail 1 and the pulley 3, so as to facilitate maintenance when necessary. There is a refractory castable in the cooling machine cylinder to avoid direct contact of high temperature materials with the cylinder wall. A boss is built at a certain position on the refractory castable. The function of the boss is to prevent the material and cooling water from m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com