Rotary multi-way valve

A multi-way valve and rotor technology, applied in multi-way valves, valve details, diaphragm valves, etc., can solve problems such as cross-contamination, liquid leakage, and easy wear of end face seals, achieving strong designability and flexible and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

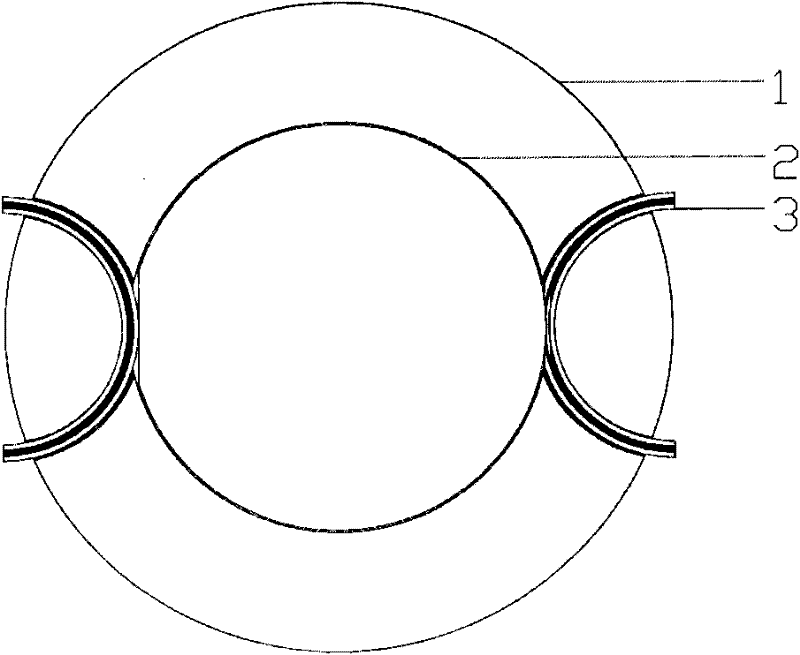

[0101] use as Figure 1a The pressure switch shown is released, the inner rotor and outer stator mode; its overall structure adopts the following Figure 2a Shown; the distribution of fluid channels on the middle plate is as follows Figure 9a As shown, the four-way distribution method is adopted; three intermediate plates are stacked, there is a chassis under it, and a top plate above, and the fastening method of the bottom plate, the middle plate and the top plate is bolted; the outer diameter of the middle plate is 160mm, the inner diameter is 108mm, and its upper surface carries the closing mechanism—the groove of the silicone tube is a semi-circular ring, the radius of the ring body is 60mm, and the corresponding circular tube diameter is 12mm; the rotor adopts such as Figure 7a , 7b , 7c and 7d show the form of the inner rotor, the diameter of the main cylinder is 100mm, the height of the gap is 10mm, the distribution of the gap is as follows Figure 7a , 7b As shown...

Embodiment 2

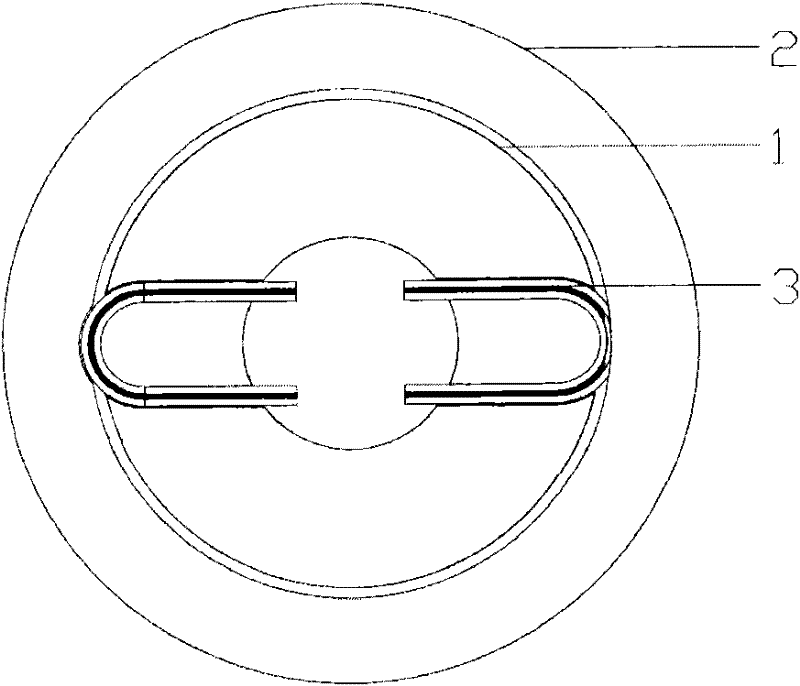

[0104] use as Figure 1d The pressure-on-release type shown is an inner stator and outer rotor mode; its overall structure adopts the following Figure 2b Shown; the distribution of fluid channels on the middle plate is as follows Figure 9b-1 As shown, the five-way distribution method is adopted; only one middle plate is used, there is a bottom plate under it, and a top plate on the top, and the fastening method of the bottom plate, the middle plate and the top plate is bolted; the outer diameter of the middle plate is 100mm , the inner diameter is 50mm, and its upper surface has a groove for carrying the closing mechanism 3 and the pressing mechanism 4; the rotor adopts such as Figure 9b-2 In the form of the outer rotor shown, the outer diameter of the main cylinder is 160mm, the inner diameter is 118mm, the height of the protrusion is 10mm, and there is only one protrusion; the closing mechanism adopts a silicone tube as shown in Figure 3a, the outer diameter is 10mm, and...

Embodiment 3

[0107] use as Figure 1d The pressure-opening and loose-closing type shown; its overall structure adopts the following Figure 2c As shown, it is the upper stator and lower rotor mode; the distribution of the fluid channels on the upper stator is as follows Figure 9c-1 As shown, a six-way distribution method is adopted; the outer diameters of the upper stator and the lower rotor are both 180mm, the inner diameter of the upper stator is 50mm, the inner diameter of the lower rotor is 70mm, the diameter of the middle shaft is 50mm, and the upper stator is fixed on the middle shaft. The lower rotor is connected to the central shaft through an ordinary bearing, the inner diameter of which is 50mm, and the outer diameter is 70mm; Institutions such as Figure 4d-1 and 4d-2 The pressure-opening-release-closing mechanism shown; the relative positional relationship of the lower rotor, the pressing mechanism and the closing mechanism are as follows: Figure 5c-2 As shown, only its i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com