Automatic machine oil cleaning system, oil return pipeline of communicating vessel, and engine system

An oil return line, automatic cleaning technology, applied in the installation/connection of lubricant conduit devices, lubricant purification devices, lubricating parts, etc., can solve the problems of low reliability, complex structure, and structural limitations of the oil pan, Achieve the effect of prolonging the replacement cycle, increasing the cleanliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

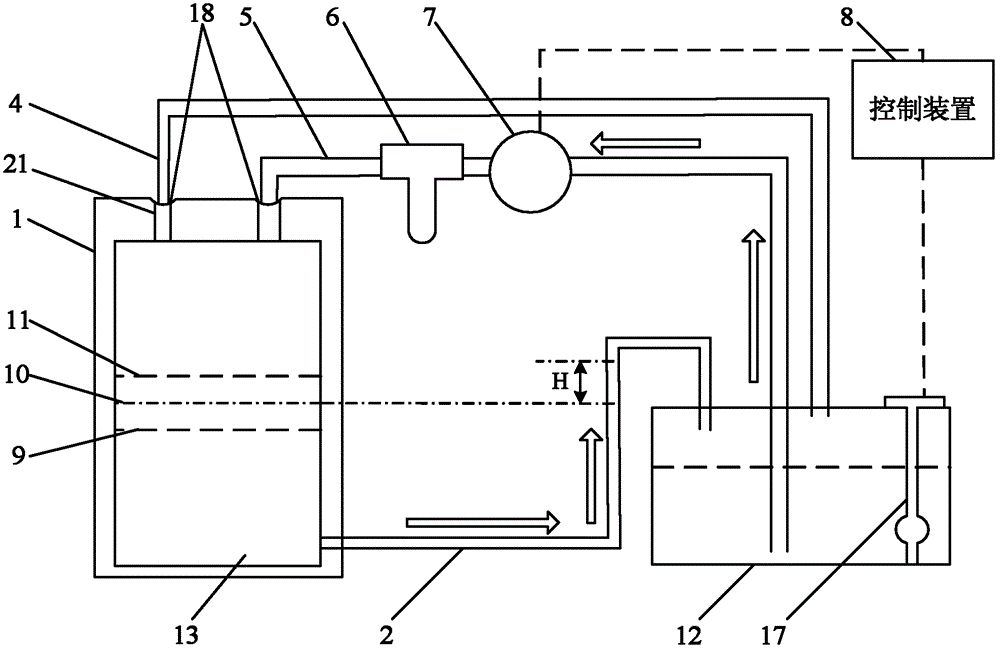

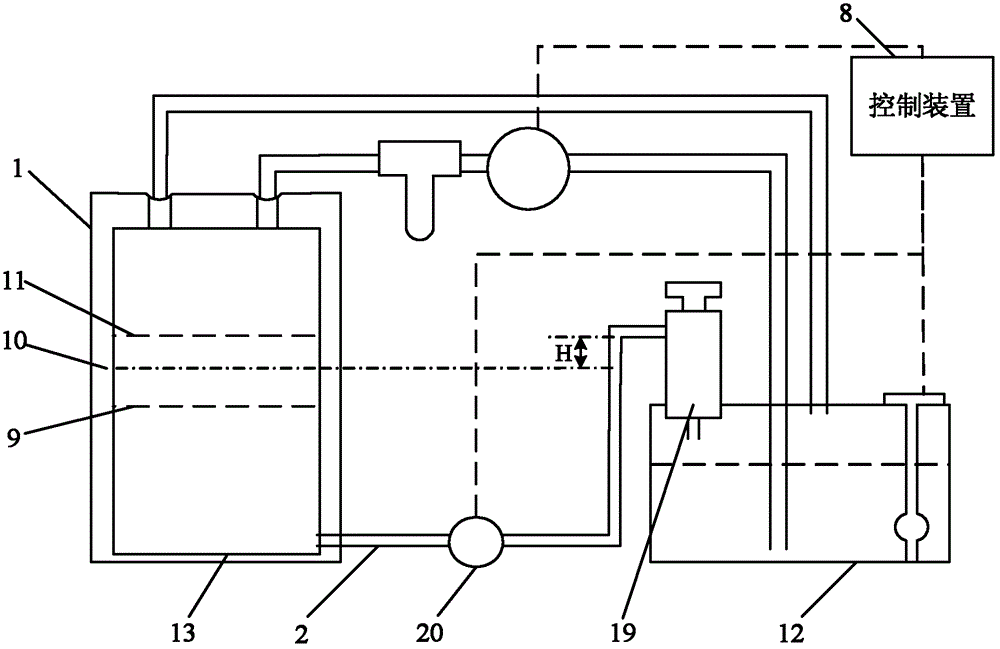

[0025] An embodiment of the present invention provides an automatic engine oil cleaning system, such as figure 1 As shown, the system includes:

[0026] Additional engine oil tank 12, is used for storing engine oil;

[0027] An oil supply device 14 communicated with the additional oil tank 12 and the engine 1 respectively, for extracting and filtering the oil in the additional oil tank 12 and then injecting it into the engine 1;

[0028] Connector oil return pipeline 2, the two ends of the connector oil return pipeline 2 respectively communicate with the bottom end of the oil pan 13 and the top end of the additional oil tank 12, the highest of the connector oil return pipeline 2 The height at the point is higher than the engine oil level height set in the oil pan 13 and has a height difference, and the engine oil level height set in the oil pan 13 is located at the maximum and minimum engine oil levels allowed by the engine Between the heights, the height difference is set a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com