Cold conveying system of mine air-conditioning and working method of cold conveying system

An air-conditioning and cooling technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve the problems of high energy consumption, high cost, poor cooling effect, etc., to improve cooling effect, reduce cooling cost, The effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

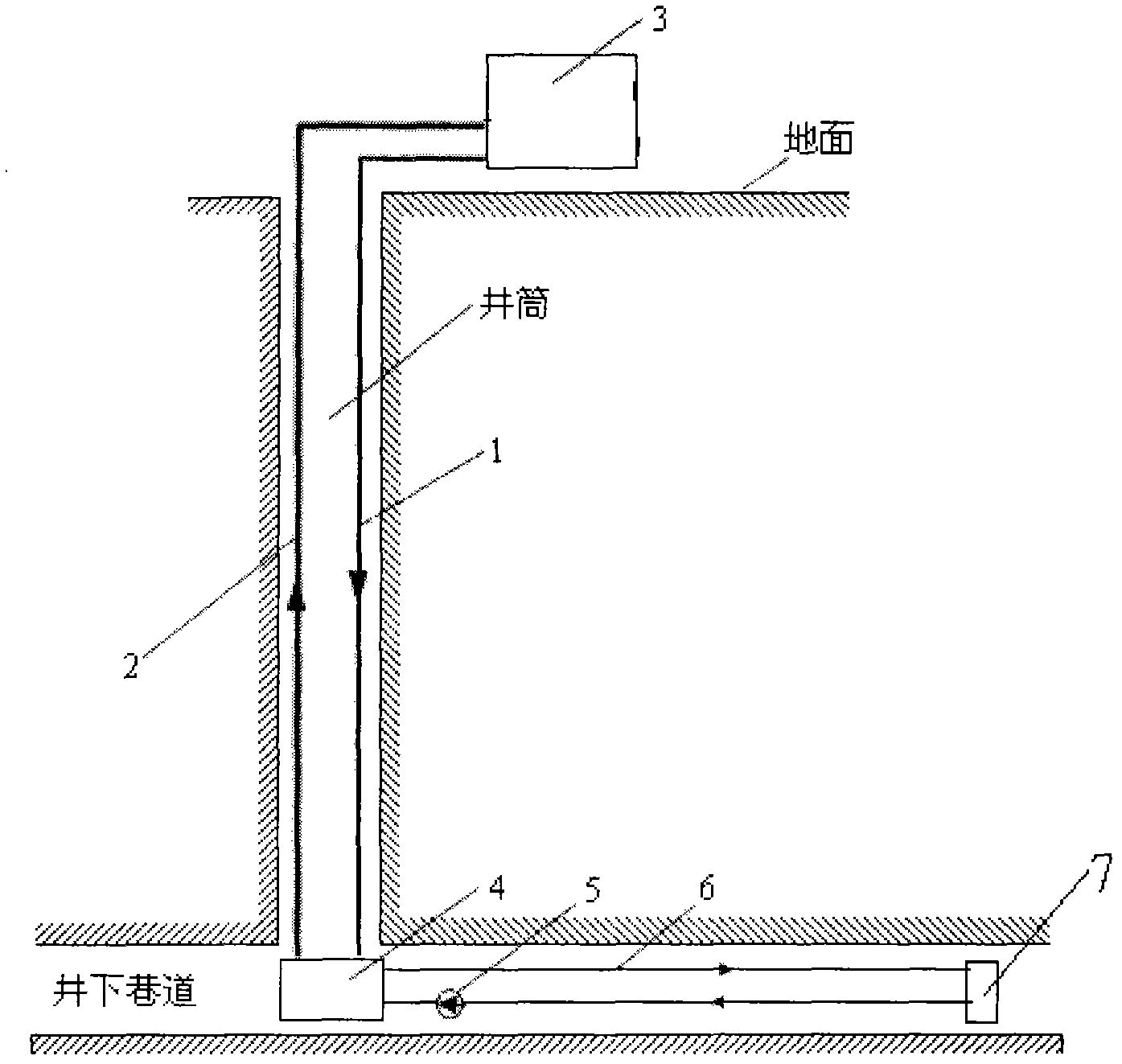

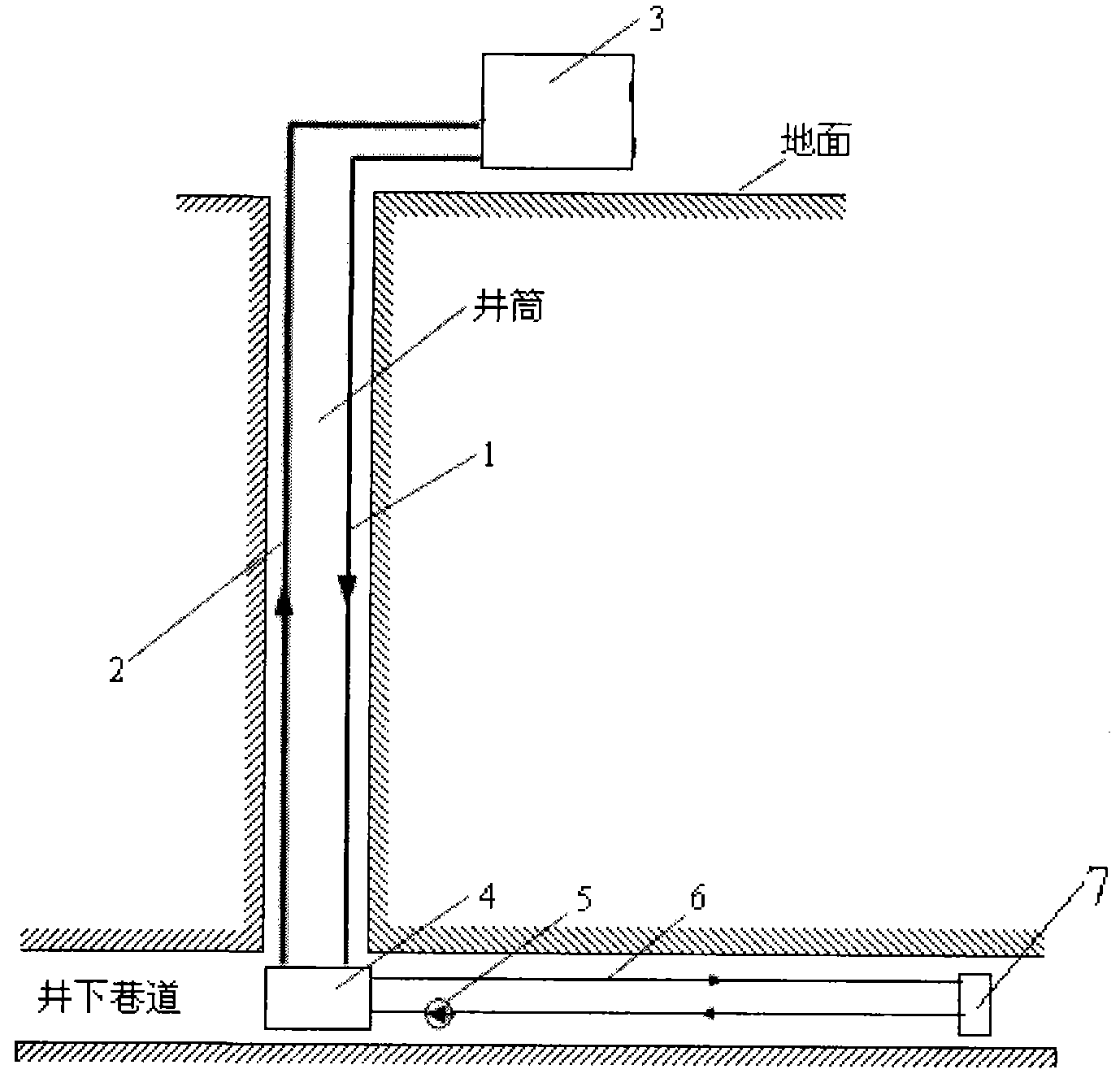

[0026] Such as figure 1 As shown, a mine air-conditioning cooling system is arranged with refrigeration equipment 3 on the ground, a heat exchanger 4 is arranged underground, and an air cooler 7 is arranged at the cooling working point of the well; refrigerant, and cold water flowing on the other side, the evaporator inlet of the ground refrigeration equipment 3 and the refrigerant outlet of the downhole heat exchanger 4 are connected by a gaseous refrigerant pipeline 2, and the evaporator outlet of the ground refrigeration equipment 3 and the downhole heat exchanger 4 The refrigerant inlets are communicated with liquid refrigerant pipes 1 to form a closed pipeline system, and a certain amount of liquid refrigerant is filled in the pipeline system; the cold water side of the downhole heat exchanger 4 is connected with the well cooling The air cooler 7 at the working point is connected through the cold water circulation pipeline 6, and the cold water circulation pump 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com