Hydraulic casing pipe centering device

A technology of centralizer and casing, applied in casing, drill pipe, drilling equipment, etc., can solve the problems of affecting drilling well production, economic loss, uneven distribution of cement sheath, etc., and achieve significant economic benefits and uniform annular gap. , Guarantee the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

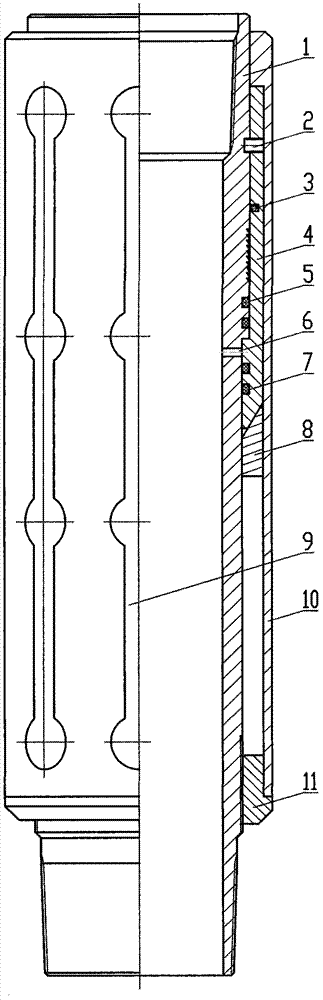

[0007] Combine first figure 1 Embodiments of the present invention will be further described.

[0008] exist figure 1 Middle: 1 is the main body, 2 is the constant pressure pin, 3 is the lock ring, 4 is the piston, 5 is the upper sealing ring, 7 is the lower sealing ring, 8 is the cone, 10 is the expansion and centralizing cylinder, and 11 is the stop sleeve. That is, the embodiment of the present invention includes a main body 1, a constant pressure pin 2, a lock ring 3, a piston 4, an upper sealing ring 5, a lower sealing ring 7, a cone 8, an expanding centralizing cylinder 10, and a retaining sleeve 11. Hole 6, the piston 4 is set outside the main body 1, the piston 4 is connected to the main body 1 by the constant pressure pin 2, there are upper sealing ring 5 and lower sealing ring 7 between the main body 1 and the piston 4, in this embodiment, the upper sealing ring 5 is installed on the outer wall of the main body 1, the lower sealing ring 7 is installed on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com