Composite lamination rubber-annular steel bar quake-isolating device

A technology of laminated rubber and composite lamination, which is applied in earthquake-proof, building components and other directions, can solve the problems of not being able to achieve vertical isolation, not being able to withstand vertical tension, not complying with environmental protection, safety and reliability, etc., and achieving a wide range of engineering application prospects. , significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

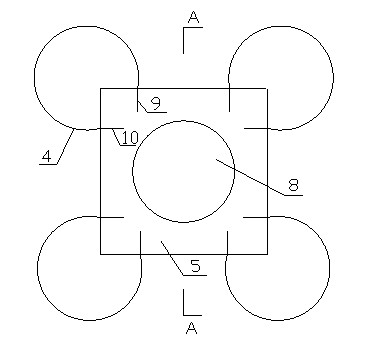

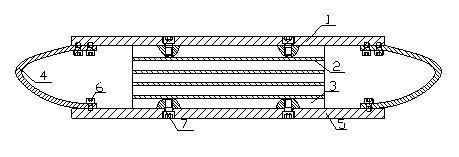

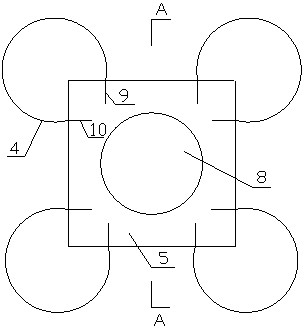

[0017] The new composite laminated rubber-ring steel rod vibration isolation device of the present invention includes: upper connecting plate 1, thin steel plate 2, rubber 3, ring steel rod 4, lower connecting plate 5, connecting bolt 6, countersunk bolt 7, The laminated rubber pad 8, the upper head 9 where the ring-shaped steel rod is connected to the upper connecting plate, and the lower head 10 where the ring-shaped steel rod is connected to the lower connecting plate. Among them, the thin steel plate 2 and the rubber 3 form a laminated rubber pad by a layer of rubber and a layer of steel plate; the laminated rubber pad and the upper connecting plate 1 and the lower connecting plate 5 adopt high-strength countersunk bolts 7 For connection, the number of connecting bolts 6 should ensure the reliable transmission of horizontal shearing force; the ring-shaped steel rods 4 are distributed around the laminated rubber pads, and the two ends are connected with the upper connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com