Construction method used for carrying out strengthening treatment on heavy haul railway bridge

A technology that strengthens treatment and construction methods, and is applied in bridges, bridge repairs, bridge reinforcement, etc., and can solve problems such as concrete weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

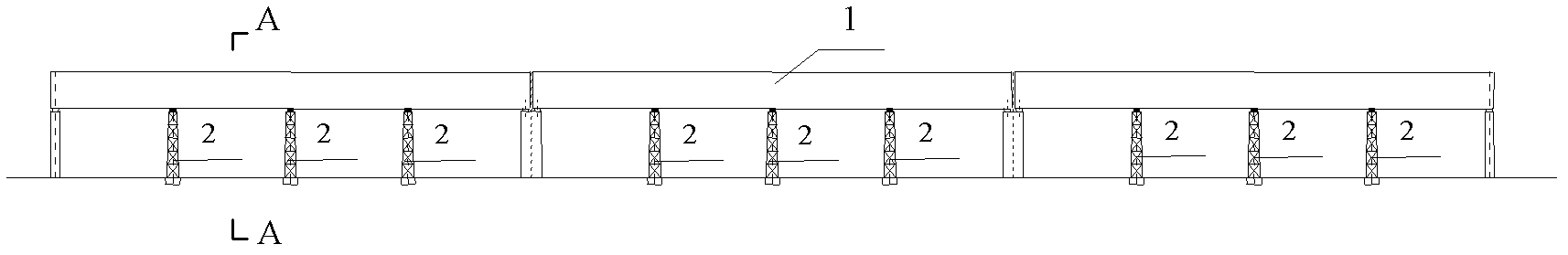

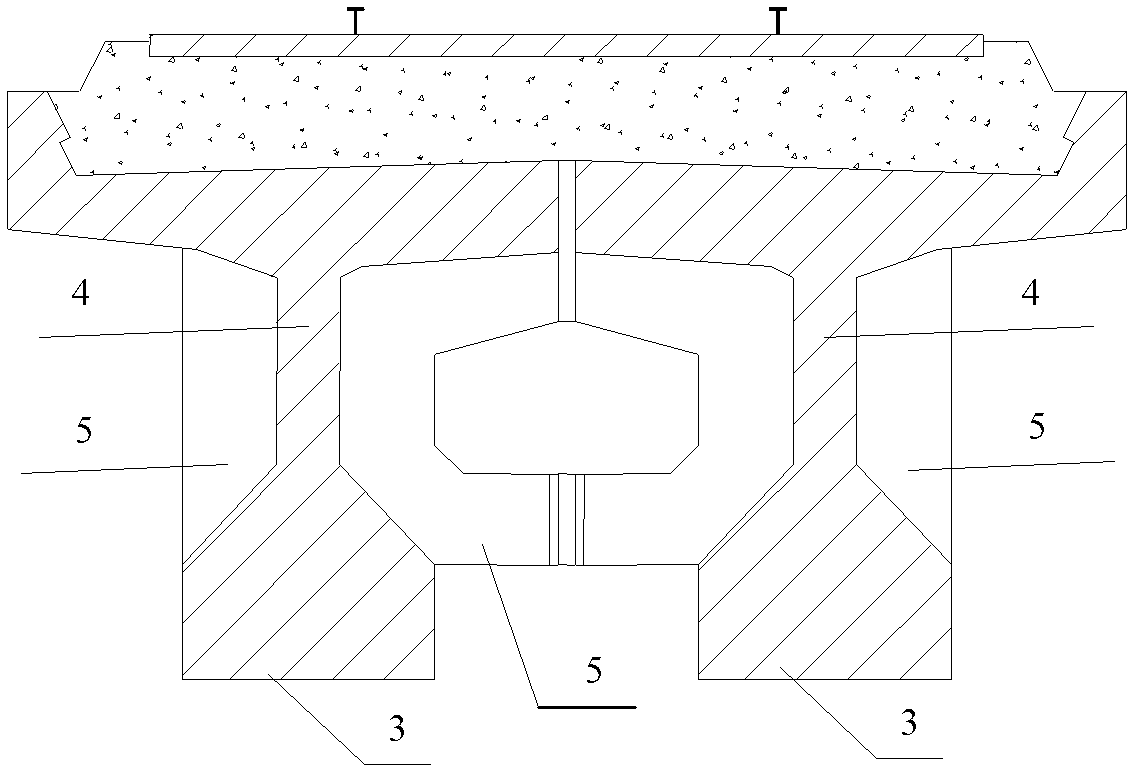

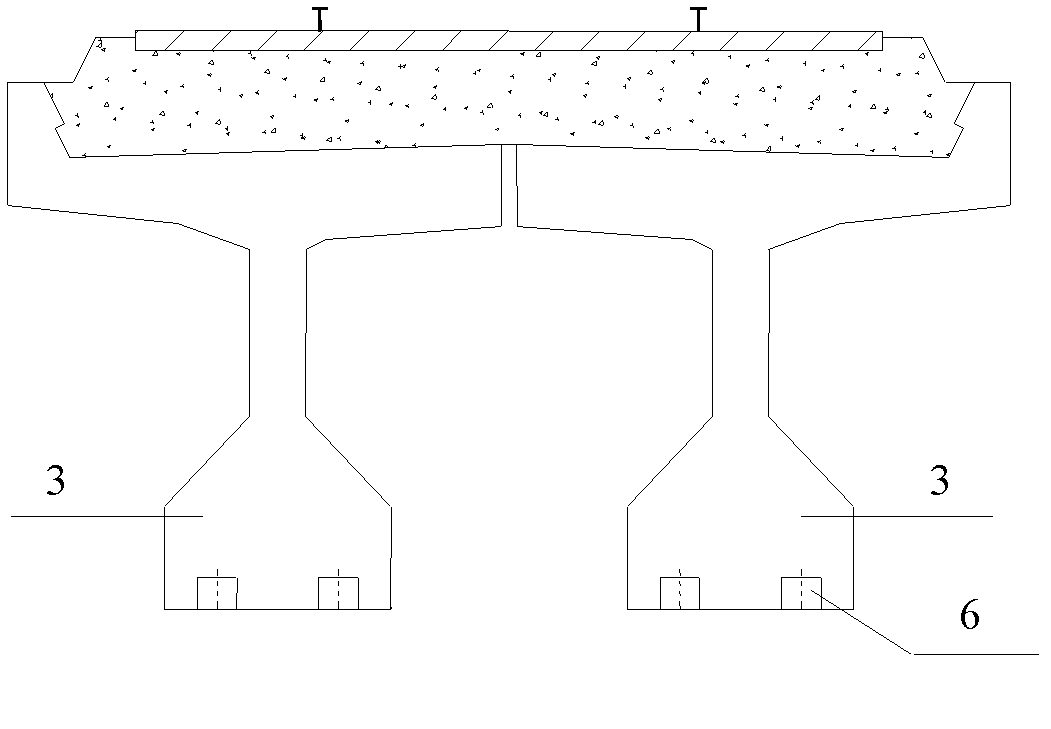

[0097] Preferred embodiments of the present invention are described below in conjunction with the accompanying drawings, wherein the reference numerals are represented as: among the figures, the reference numerals are represented as: 1-concrete T beam; 2-reverse top support; 3-concrete T beam bottom plate; 4 -Concrete T-beam web; 5-Concrete T-beam diaphragm; 6-Micro-expansion self-compacting concrete pouring hole; Concrete; 12-the concrete surface of the original T-beam bottom slab; 13-the portal steel bar.

[0098] The solution of the present invention is to provide a construction method for strengthening the heavy-duty railway bridge on the basis of the prior art. Plant reinforcement, inject micro-expansion self-compacting concrete between the bottom and side web of the original concrete beam and the reinforced steel plate at the same time to make the reinforced part work together with the original structure as a whole. The original concrete beam includes the existing concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Slump spread | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com